Housing of an electric machine having an optimized sealing ring

A casing and casing cover technology, which is applied to the sealing of the engine, the casing/cover/support, electromechanical devices, etc., can solve the problems of cooling loss, drive unit stop operation, interference, etc., to achieve easy processing and prevent escape. Out, optimize the effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

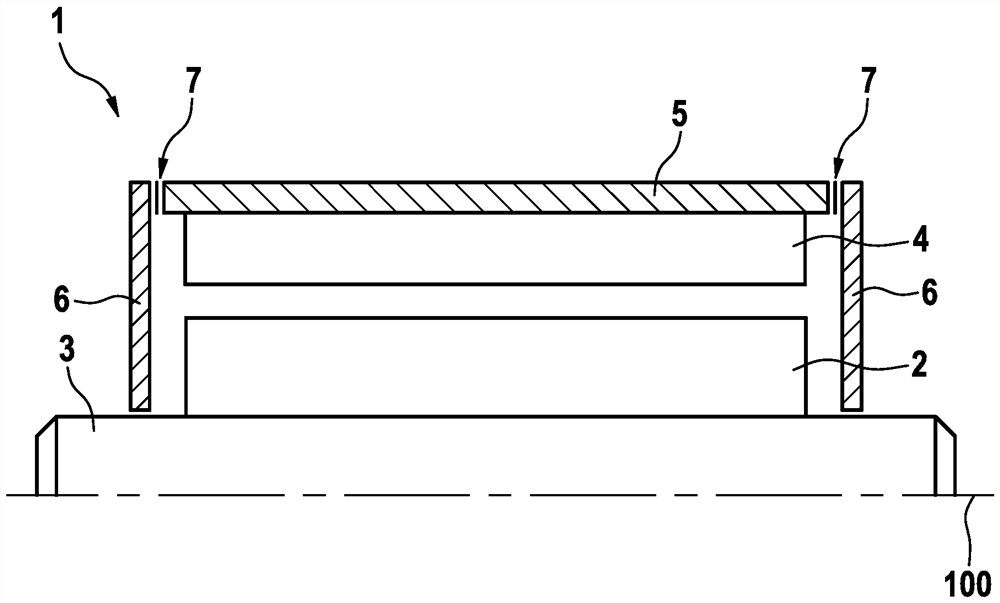

[0032] figure 1 An electric machine 1 according to an embodiment of the invention is shown schematically. The electric machine 1 comprises a rotor shaft 3 on which the rotor 2 is mounted. The rotor shaft 3 extends along a housing axis 100 of the housing of the electric machine 1 . Furthermore, the electric machine 1 includes a housing element 5 which is designed as a hollow cylinder and carries the stator 4 . The rotor 2 can be driven via the stator 4 so that the rotor shaft 3 can rotate. In particular, the housing axis 100 forms the central axis of the housing element 5 .

[0033] The housing has at least one housing cover 6 which is attached to the end face 7 of the housing element 5 . A gasket 7 is mounted between the housing cover 6 and the housing element 5 . Below, refer to Figure 2 to Figure 7 The interaction of housing element 5 , housing cover 6 and gasket 7 is explained in more detail.

[0034] figure 2 A schematic exploded view of a partial area of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com