Radon measurement dehumidification method

A radon chamber and flowmeter technology, which is applied in measurement devices, radiation measurement, X/γ/cosmic radiation measurement, etc., can solve the problems of inconvenience and cost of radon measuring instruments, improve portability and measurement efficiency, reduce usage Volume, volume and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides a radon measurement and dehumidification method, the specific steps are as follows:

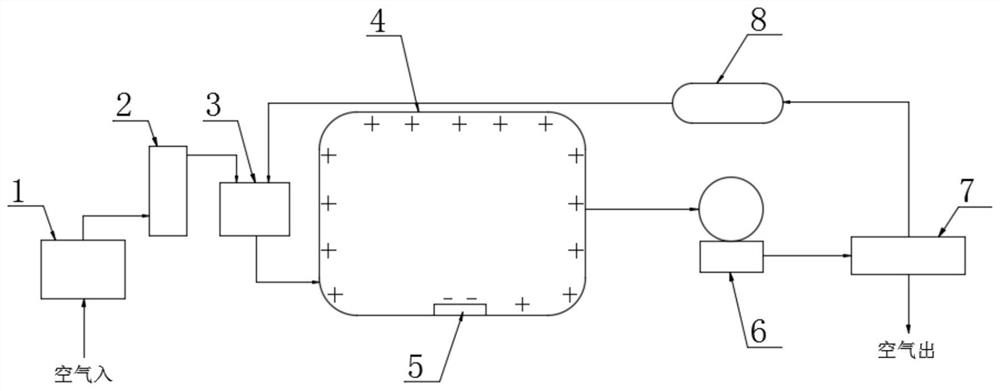

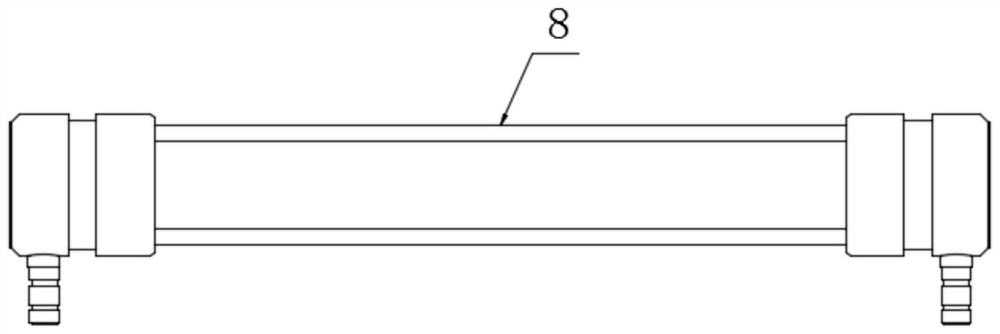

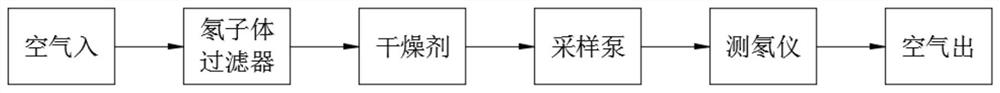

[0022] Step 1: Prepare radon daughter filter 1, flowmeter 2, first solenoid valve 3, radon measuring chamber 4, detector 5, pump 6, second solenoid valve 7 and drying pipe 8, and the detector 5 is installed on Measuring the inside of the radon chamber 4;

[0023] Step 2: The output end of the radon daughter filter 1 is connected to the input end of the flow meter 2, the output end of the flow meter 2 is connected to the input end of the first electromagnetic valve 3, and the output end of the first electromagnetic valve 3 The output end is connected to the input end of the radon measuring chamber 4, the output end of the radon measuring chamber 4 is connected to the input end of the pump 6, and the output end of the pump 6 is connected to the input end of the second solenoid valve 7, and the second electromagnetic valve 7 is connected to the output end of the pum...

Embodiment 2

[0028] The invention provides a radon measurement and dehumidification method, the specific steps are as follows:

[0029] Step 1: Prepare radon daughter filter 1, flowmeter 2, first solenoid valve 3, radon measuring chamber 4, detector 5, pump 6, second solenoid valve 7 and drying pipe 8, and the detector 5 is installed on Measuring the inside of the radon chamber 4;

[0030] Step 2: The output end of the radon daughter filter 1 is connected to the input end of the flow meter 2, the output end of the flow meter 2 is connected to the input end of the first electromagnetic valve 3, and the output end of the first electromagnetic valve 3 The output end is connected to the input end of the radon measuring chamber 4, the output end of the radon measuring chamber 4 is connected to the input end of the pump 6, and the output end of the pump 6 is connected to the input end of the second solenoid valve 7, and the second electromagnetic valve 7 is connected to the output end of the pum...

Embodiment 3

[0035] The invention provides a radon measurement and dehumidification method, the specific steps are as follows:

[0036] Step 1: Prepare radon daughter filter 1, flowmeter 2, first solenoid valve 3, radon measuring chamber 4, detector 5, pump 6, second solenoid valve 7 and drying pipe 8, and the detector 5 is installed on Measuring the inside of the radon chamber 4;

[0037] Step 2: The output end of the radon daughter filter 1 is connected to the input end of the flow meter 2, the output end of the flow meter 2 is connected to the input end of the first electromagnetic valve 3, and the output end of the first electromagnetic valve 3 The output end is connected to the input end of the radon measuring chamber 4, the output end of the radon measuring chamber 4 is connected to the input end of the pump 6, and the output end of the pump 6 is connected to the input end of the second solenoid valve 7, and the second electromagnetic valve 7 is connected to the output end of the pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com