High-pressure gas flow control device for wind tunnel test

A flow control device and high-pressure gas technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve problems such as difficult to meet high precision and wide range, difficult to replace the sonic nozzle, low measurement accuracy, etc. Achieve the effects of avoiding the reduction of measurement accuracy, simple structure, and widening the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

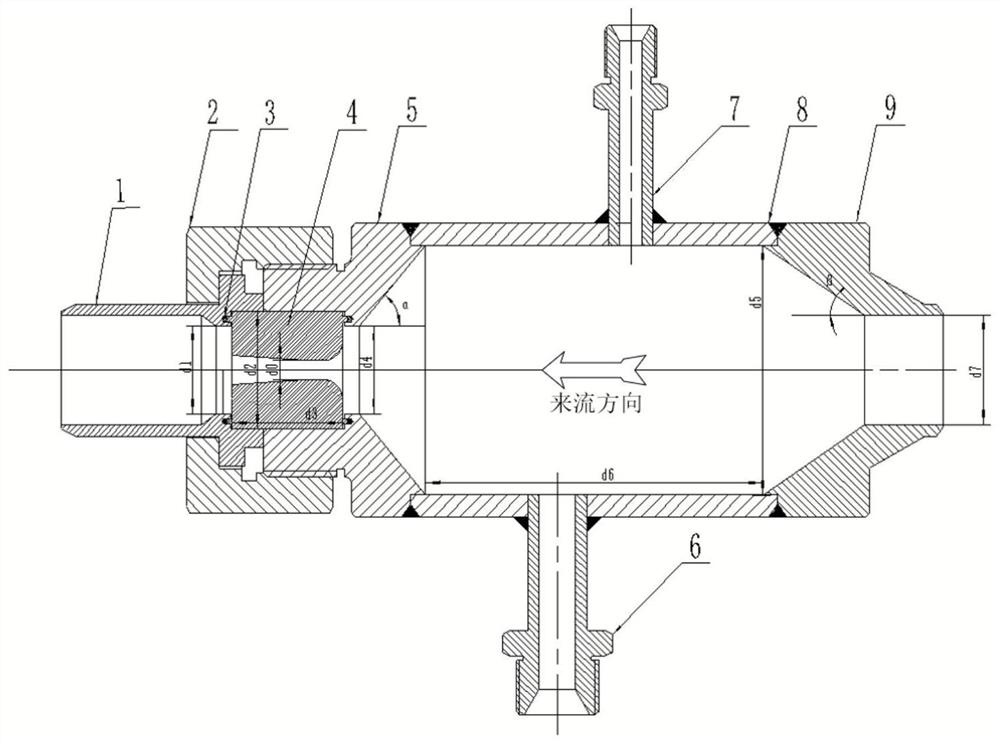

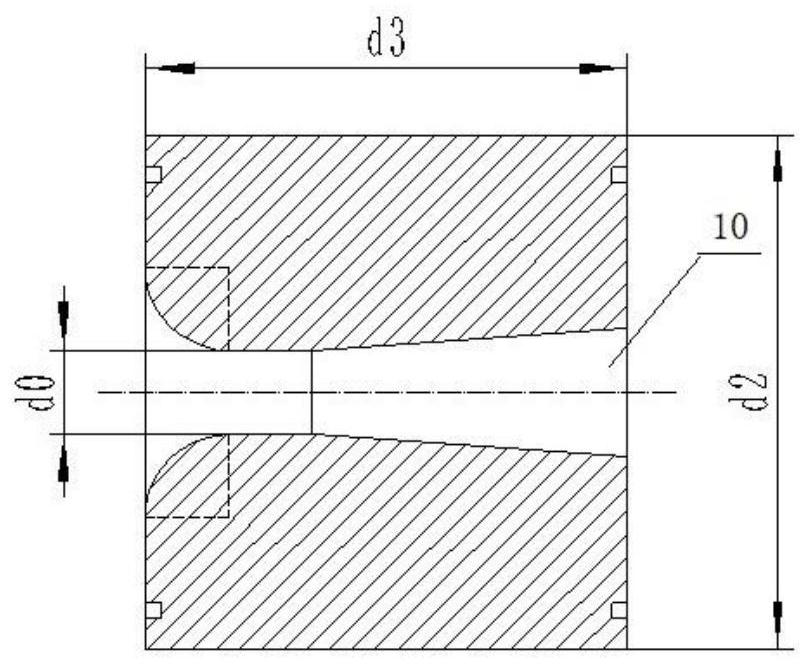

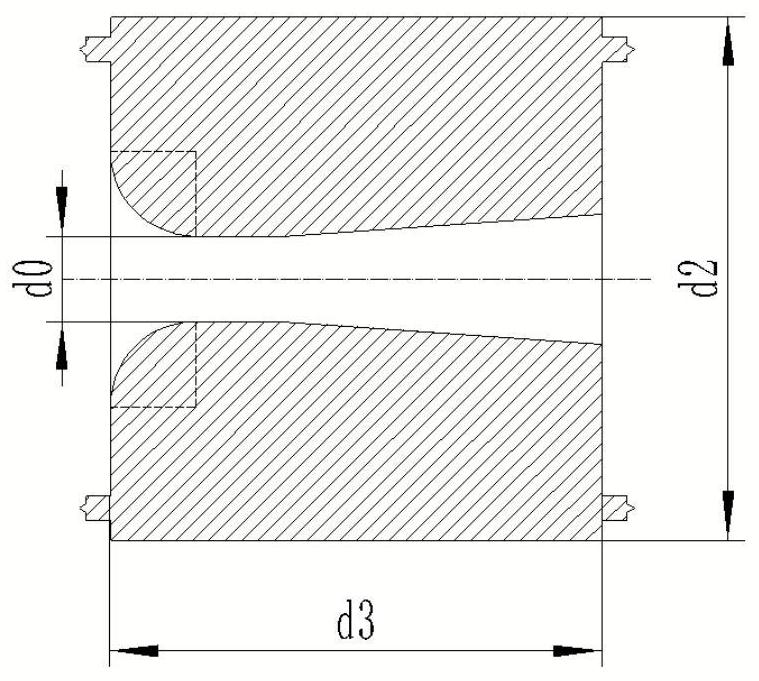

[0034] Such as figure 1 As shown, this embodiment takes the high-pressure gas flow control device for wind tunnel tests with a connecting pipe of φ30 and a maximum nozzle throat of φ6.5 as an example, including a rear transition section 1, a nut pressure cap 2, a sonic nozzle 4, and a nozzle The transition section 5, the steady flow chamber 8, the front transition section 9, the gasket 3, the pressure measurement connector 7 and the temperature measurement connector 6, the front end of the rear transition section 1 is connected to the downstream pressure pipeline, and the nozzle turns The sonic nozzle 4 is installed on the connection section 5, and the front and rear ends of the sonic nozzle 4 are respectively provided with sealing gaskets 3, and the sonic nozzle 4 and the rear transition section 1 are clamped by the nut pressing cap 2. More specifically, the nut pressing cap 2 It is threadedly connected with the nozzle adapter section 5, and the front transition section 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com