Slipknot screw type rapid combined circular quality system with guide rod

A quality system, screw-type technology, applied in the direction of measuring devices, machine/structural component testing, vibration testing, etc., can solve the problem of inconvenient use, high cost of monolithic mass production, and the horizontal direction of the quality system without guiding devices Limit function and other issues to achieve the effect of preventing horizontal movement and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

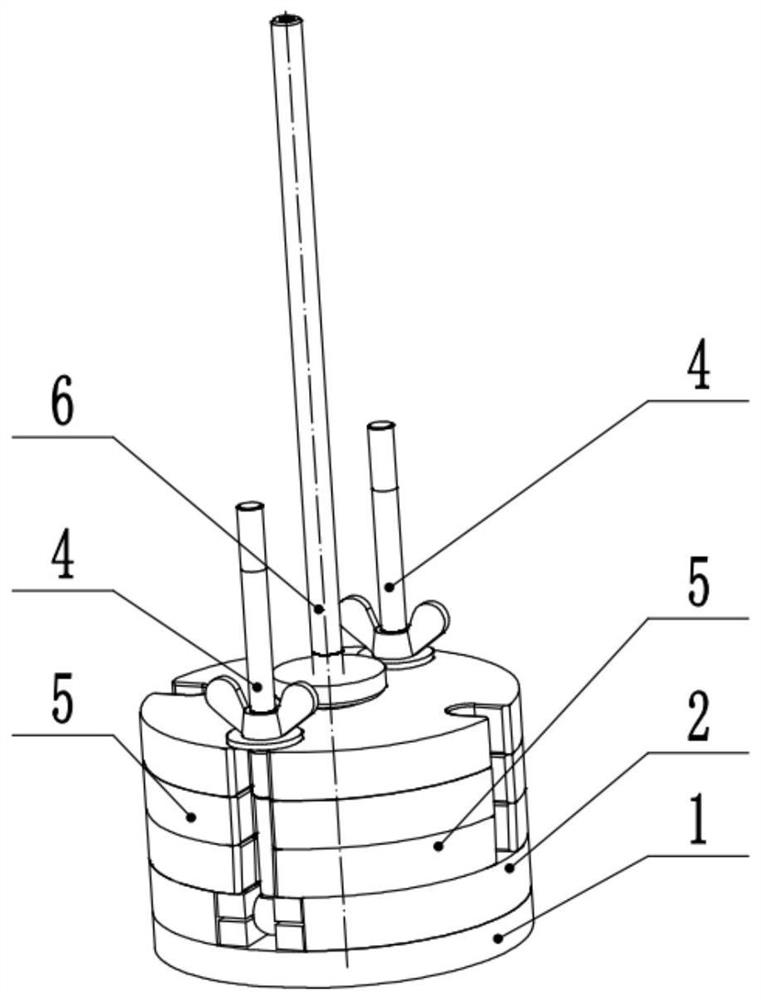

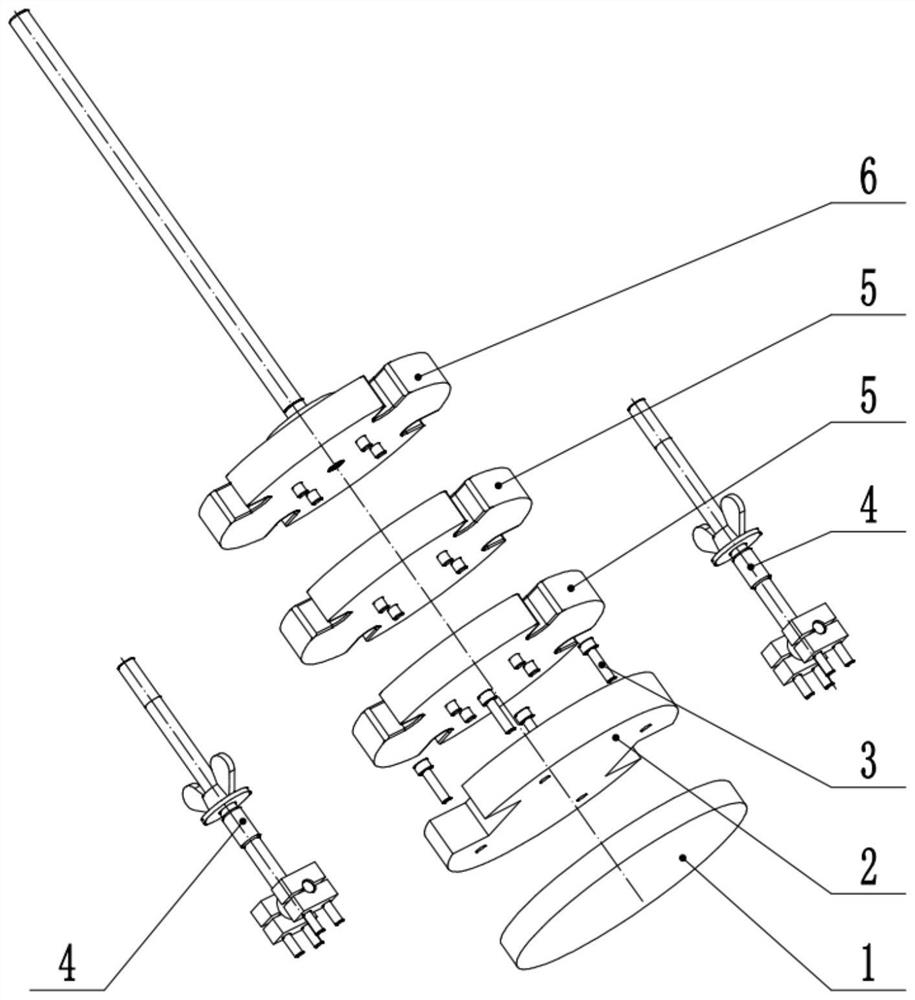

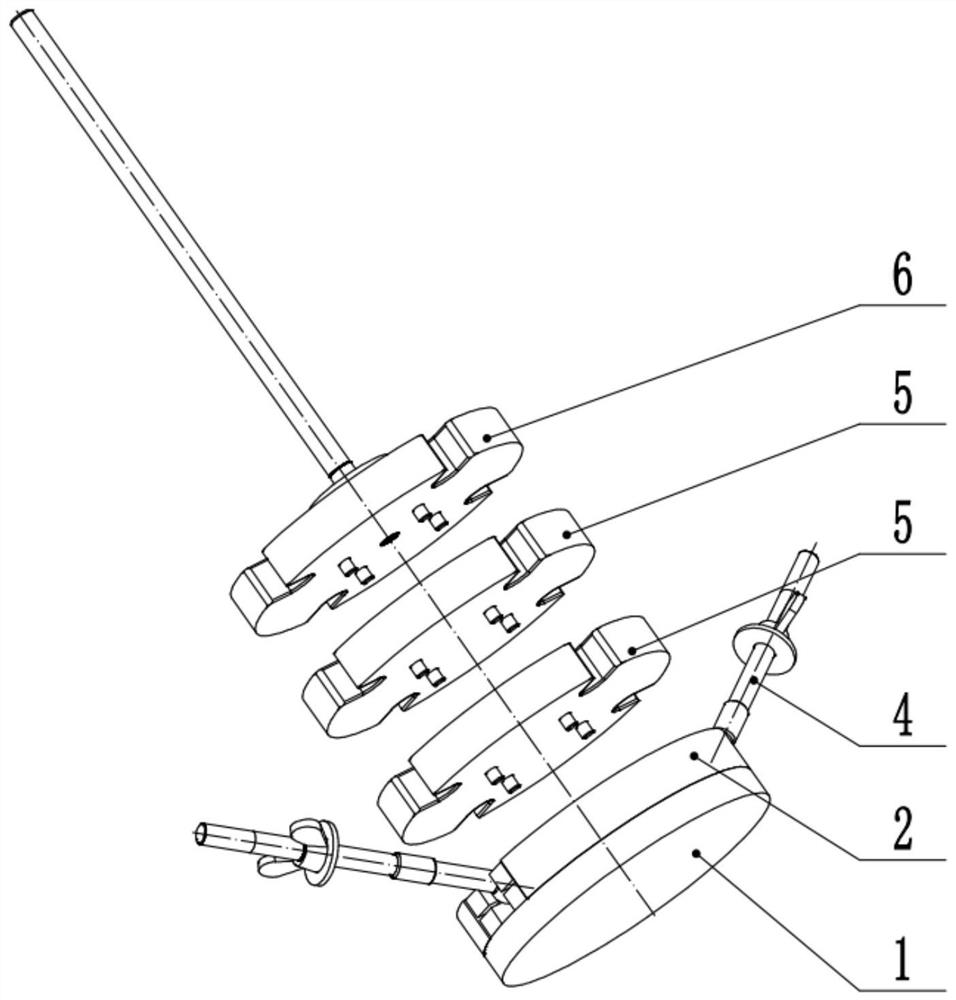

[0023] Refer to attached figure 1 , attached figure 2 And attached image 3 , a slipknot screw type rapid combination circular quality system with a guide rod, the bottom surface is a circular structure, which is quickly locked by a weight type combination and a slipknot screw combination, with a single rod guide device on the top; it includes a circular bottom plate of the quality system (1), circular backing plate (2), hexagon socket bolt A (3), slipknot screw assembly (4), weight type mass group (5), and top plate combination (6), wherein the circular backing plate (2 ) is fixed to the circular bottom plate (1) of the mass system by bolts, and a pair of slipknot screw assemblies (4) are placed in the slotted position of the circular backing plate (2) and fixed to the circular bottom plate (1) of the mass system by bolts; The code-type mass group (5) and the top plate combination (6) are aligned and placed above the circular backing plate (2) in sequence, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com