Support plate flame stabilizer with fin vortex generators

A vortex generator and flame stabilizer technology, applied in the aviation field, can solve the problems of combustion instability, amplify combustion instability, and affect the combustion reaction process, so as to improve the afterburner combustion efficiency, strengthen the heat and mass convection transmission, and improve the flame The effect of propagation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

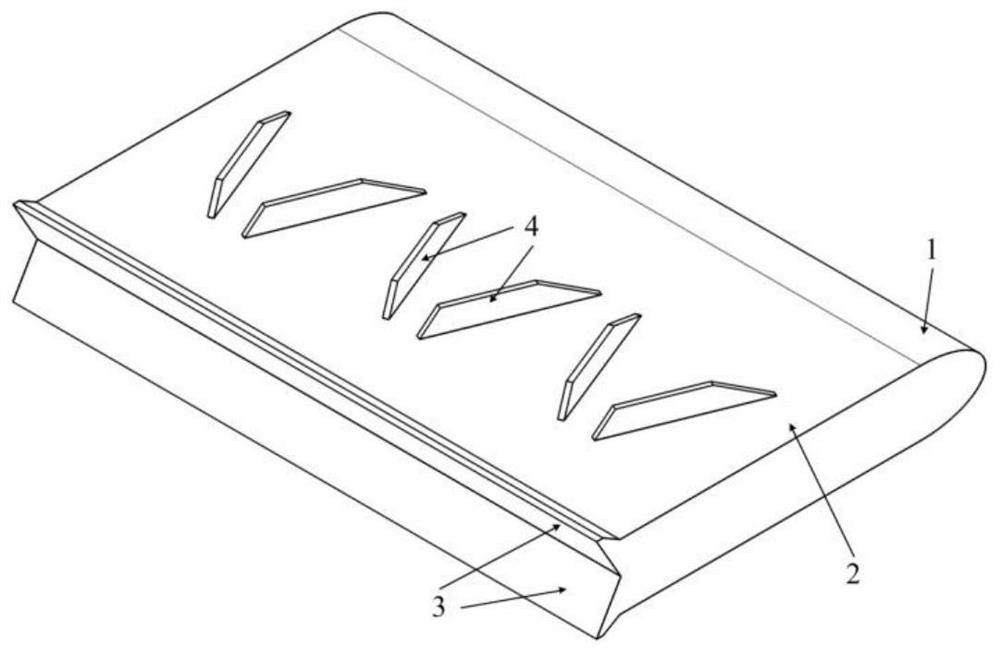

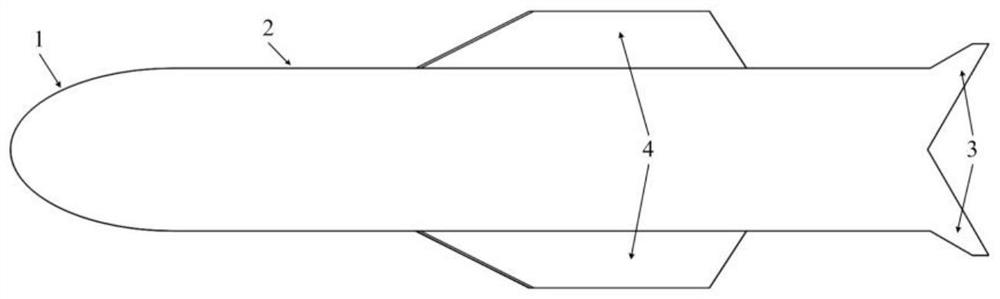

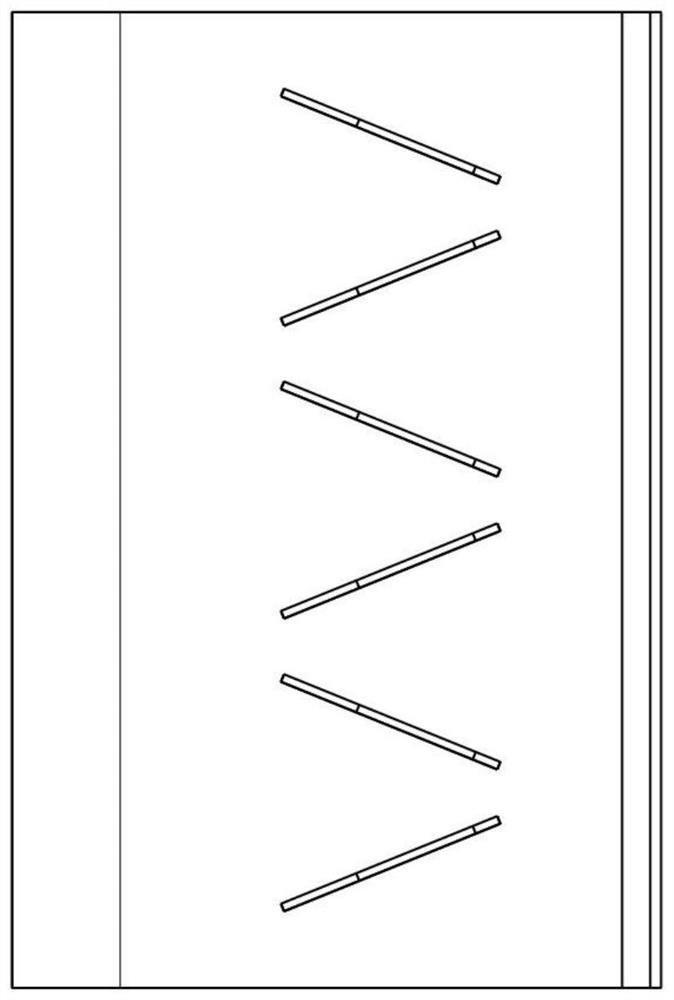

[0023] The following will be combined with Figure 1~5 The present invention is described in further detail with embodiment.

[0024] A support plate flame stabilizer with finned vortex generators, 3 to 5 pairs of finned vortex generators 4 are arranged on both sides of the support plate flame stabilizer, specifically 3 pairs in this embodiment, the support plate flame The stabilizer has a chord length of 90 to 150mm, specifically 120mm in this embodiment, and the extension length is determined by a specific engine, specifically 180mm in this embodiment, and is mainly composed of a leading edge 1, a straight section 2, and a V-shaped trailing edge 3. The edge 1 is an elliptical surface, and the major axis of the ellipse is 1.75 to 2.5 times the minor axis. In this embodiment, it is 2 times. The leading edge 1 is tangent to the straight section 2, and the straight section 2 is 18 to 28mm wide. The embodiment is specifically 20mm, the width of the V-shaped trailing edge 3 is 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com