Knitting element guide bar assembly of warp knitting machine

A braiding element and bar technology, applied in the field of braiding element bar assemblies, can solve problems such as time consumption, damage, and threaded fasteners falling, and achieve the effect of simple replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

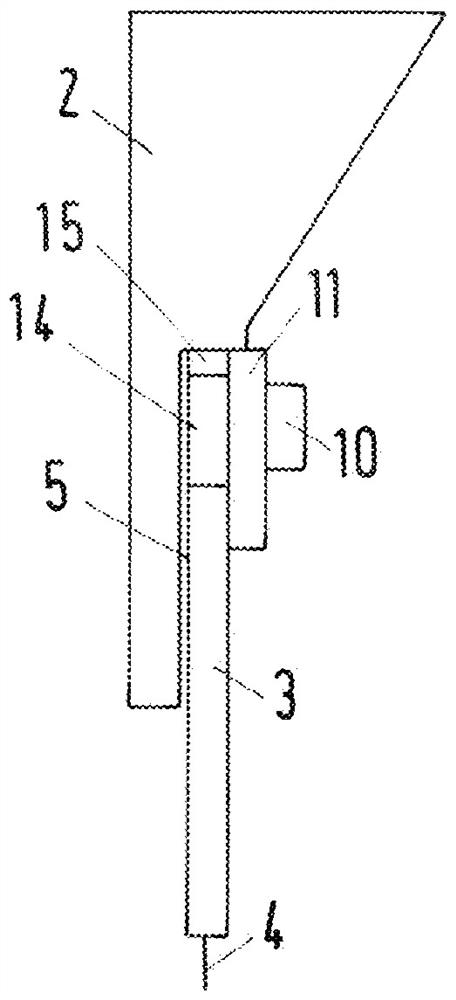

[0026] figure 1 A knitting element bar assembly 1 of a warp knitting machine is schematically shown. The bar assembly 1 has a bar 2 and a plurality of knitting element units 3 . Each knitting element unit 3 has a plurality of knitting elements 4 , which in the present case can be designed as laying needles. The knitting element unit 3 has a bar contact surface 5 with which the knitting element unit rests against the bar 3 . As will be described further below, each knitting element unit 3 is fastened detachably on the bar 2 .

[0027] exist figure 1 Three knitting element units 3 are shown in . The right knitting element unit 3 is only in contact with the bar 2 and is not already fixed there.

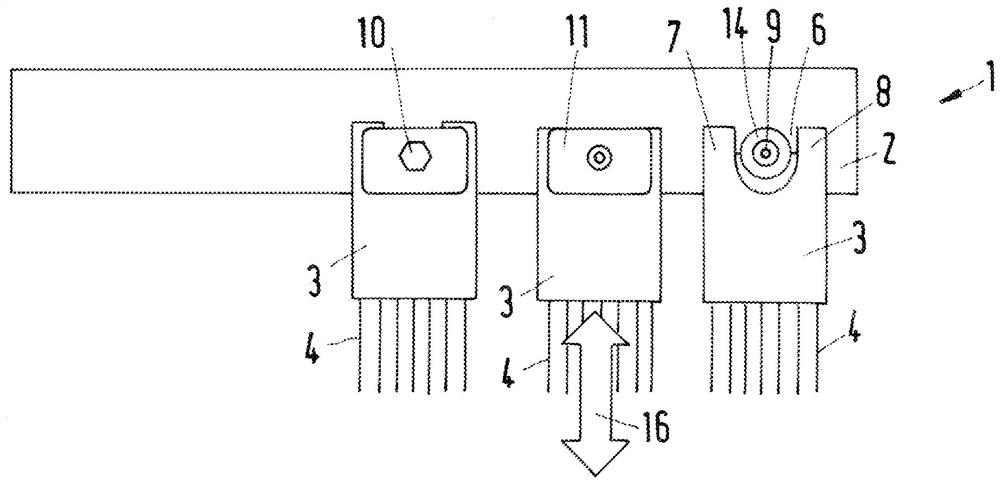

[0028] It can be seen that knit element unit 3 has a recess 6 which is open towards the edge of knit element unit 3 , that is to say on the side of knit element unit 3 facing away from knit element 4 .

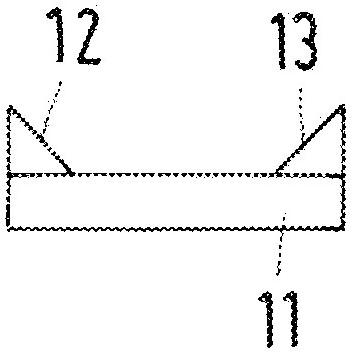

[0029] The recess 6 is bounded laterally by two feet 7 , 8 , so that it has es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com