Gypsum board lifting machine

A technology for gypsum boards and cranes, which is applied to cranes, traveling mechanisms, transportation and packaging, etc. It can solve the problems of low production efficiency and high labor intensity, and achieve the effects of high production efficiency, low labor cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

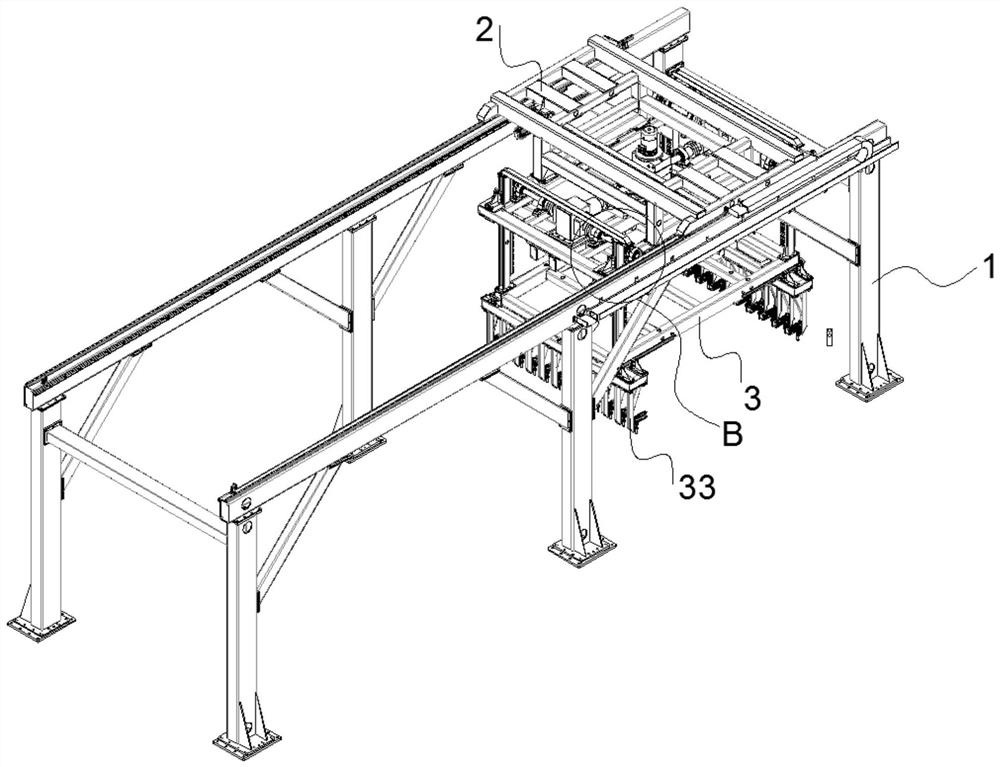

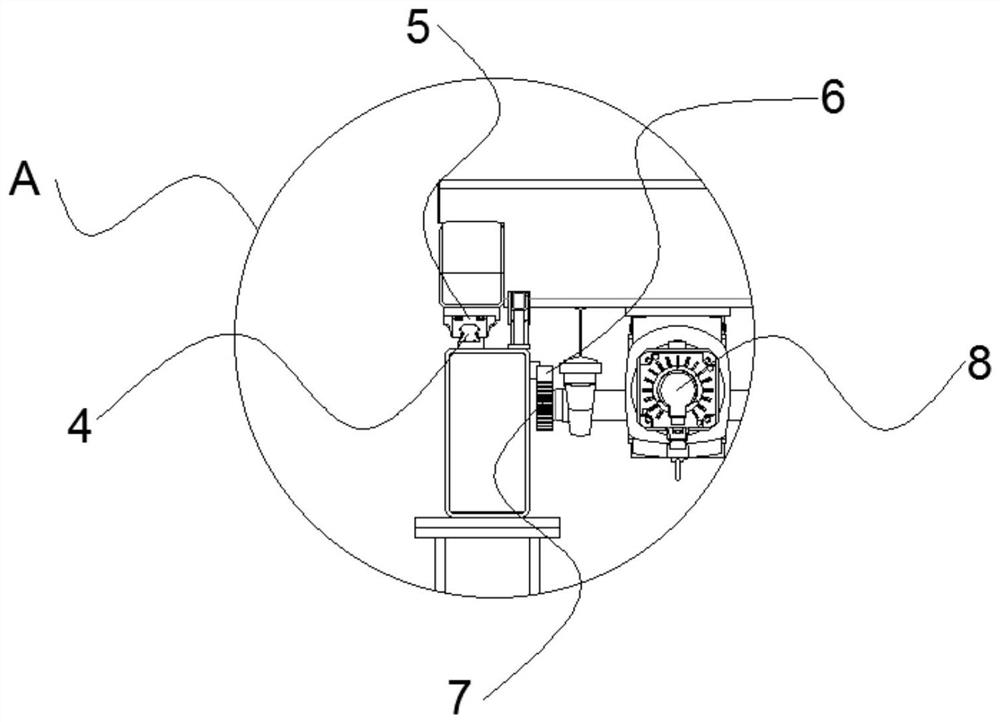

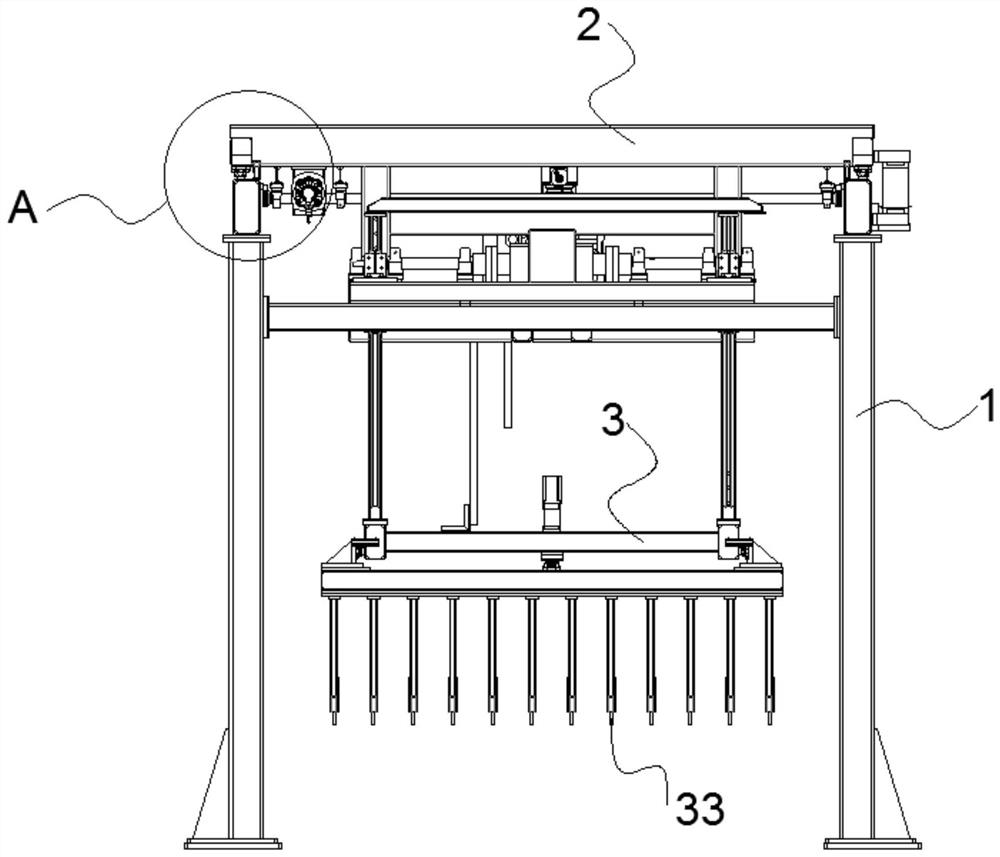

[0033] A gypsum board hoist, such as Figure 1-Figure 11 As shown, it includes a fixed frame 1 and a first frame body 2 located on the fixed frame 1. The fixed frame 1 is provided with a first drive assembly for driving the first frame body 2 to move horizontally along the hoisting direction. The frame 1 is provided with a second frame body 3 and a second driving assembly for driving the second frame body 3 up and down. The second frame body 3 is provided with a clamping assembly 33 and is used for driving the clamping assembly 33 to open and close. The third drive component;

[0034] It also includes an RFID system and a number of model cars, the RFID system includes an electrical cabinet, a reader and a number of electronic notes, the reader is set on the fixed frame 1, and a number of the electronic tags are used to store the specification data of the gypsum board and are respectively arranged on corresponding mold cars, and the first drive assembly, the second drive assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com