Mixing device for polyolefin production

A mixing device and polyolefin technology, applied in the direction of mixers, shaking/oscillating/vibrating mixers, dissolving, etc., can solve the problems of cumbersome mixing operations and low efficiency, and achieve the effect of reducing workload and speeding up mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

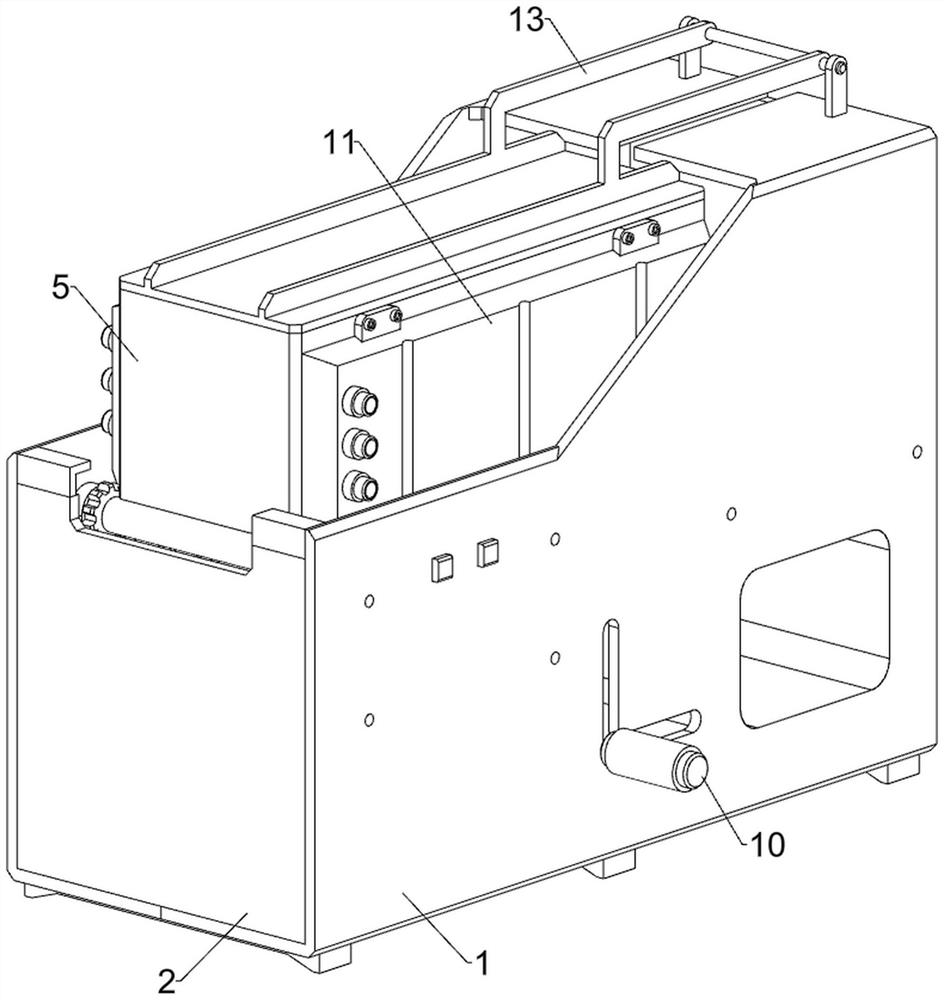

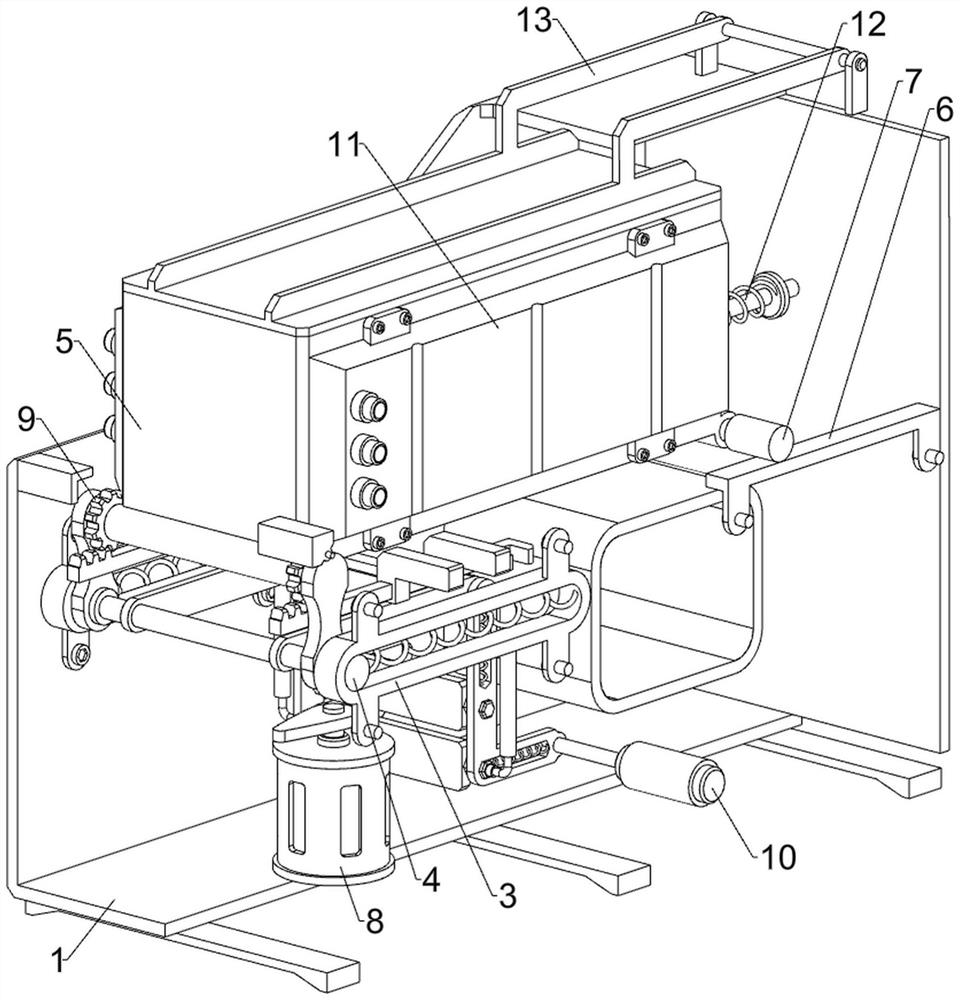

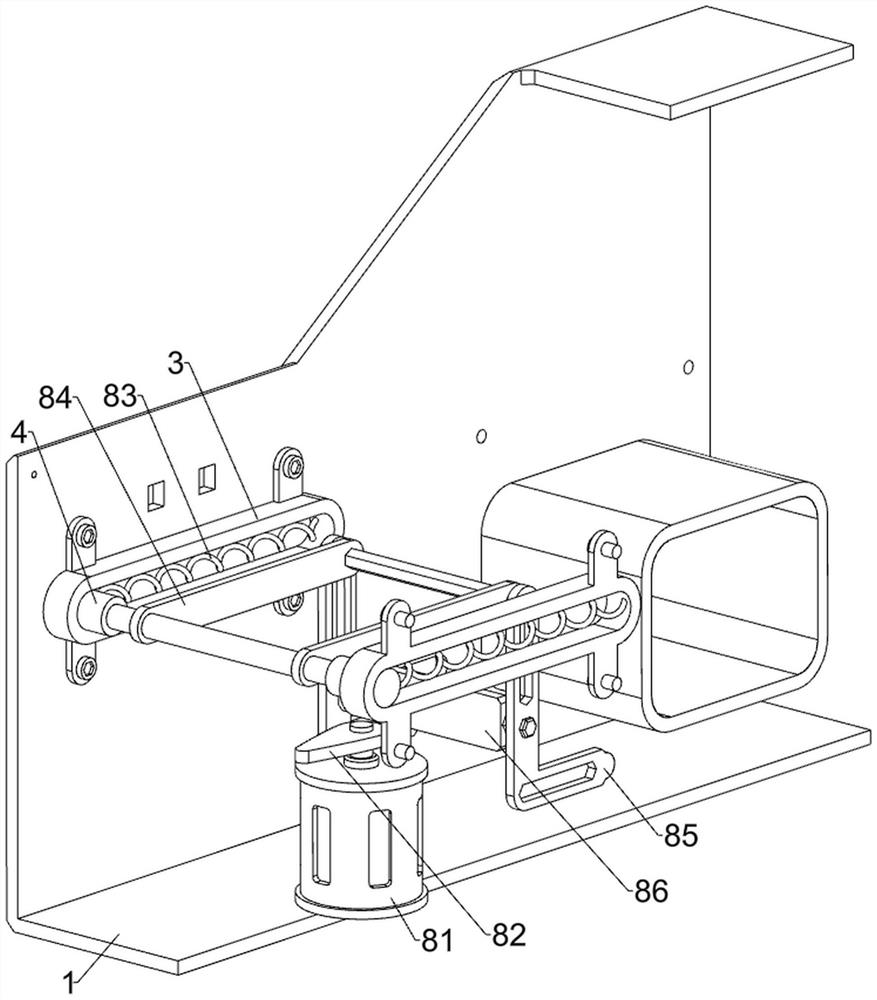

[0030] A mixing device for polyolefin production, such as Figure 1-8 As shown, it includes a housing 1, a side plate 2, a guide rail 3, a sliding rod 4, a mixing frame 5, a guide plate 6, a cross bar 7, a pushing assembly 8 and a flipping assembly 9, and the left and right sides of the housing 1 are provided with side plates 2. There are guide rails 3 on the front and rear sides of the left part of the housing 1. A sliding rod 4 is installed between the front and rear guide rails 3, and a mixing frame 5 is installed on the upper part of the sliding rod 4. The right part of the housing 1 Guide plates 6 are provided on the front and rear sides, and a crossbar 7 is provided at the lower right part of the mixing frame 5. Turning assembly 9 is provided between.

[0031] When using the device, the staff pours the melted polyolefin and other raw materials into the mixing frame 5, and then drives the sliding rod 4 to slide left and right in the guide rail 3 by pushing the component ...

Embodiment 2

[0037] On the basis of Example 1, such as figure 1 , figure 2 and Figure 5As shown, a pull assembly 10 is also included, and the pull assembly 10 includes a second contact plate 101, a handle 102, a second spring 103, a pull rod 104 and a third spring 105, and a sliding arrangement is arranged between the front and rear two right-angle plates 85 bottoms. There is a second contact plate 101, the second contact plate 101 cooperates with the cam 82, the right angle plate 85 bottom right side is provided with a handle 102, and the second spring 103 is connected between the right angle plate 85 and the second contact plate 101. Two contact plates 101 are provided with pull rods 104 on the front and rear sides, and the pull rods 104 are all matched with the rack 92 , and a third spring 105 is connected between the right-angle plate 85 and the horizontal plate 84 .

[0038] When using this device, after the polyolefin mixing is completed, the staff drives the right-angle plate 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com