Automatic cleaning equipment

An automatic cleaning and cleaning technology, applied in the field of cleaning robots, can solve the problems of inability to clean the water, the ground is covered with water, and the water flow is large, and the effect of avoiding excessive and uneven water flow is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

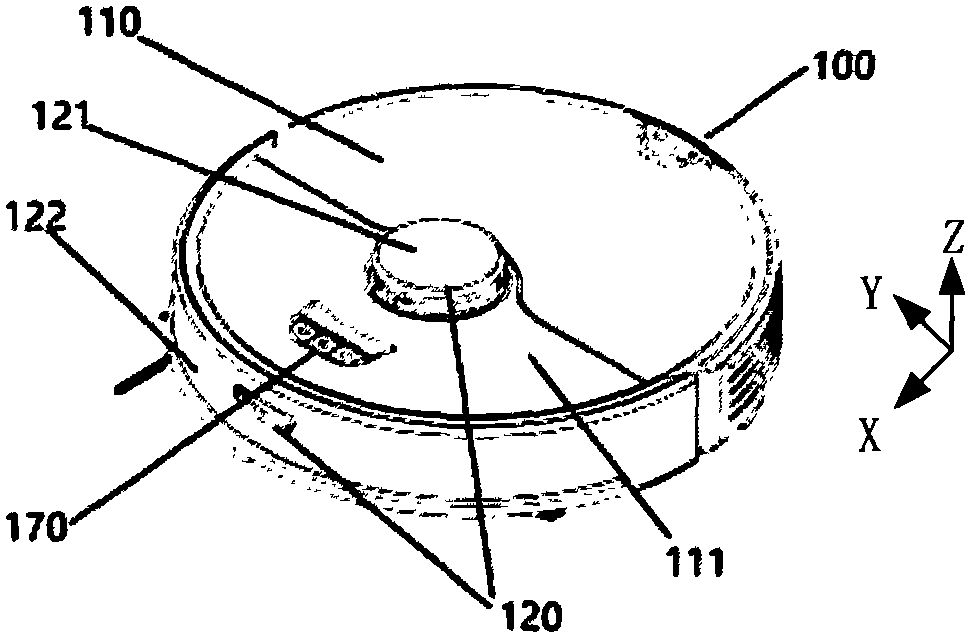

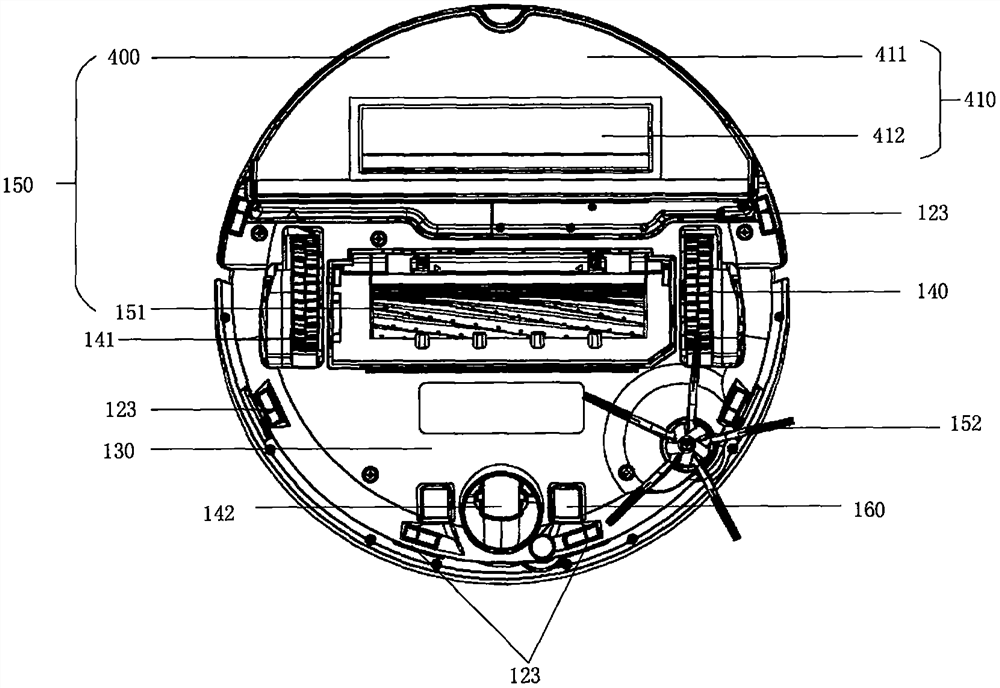

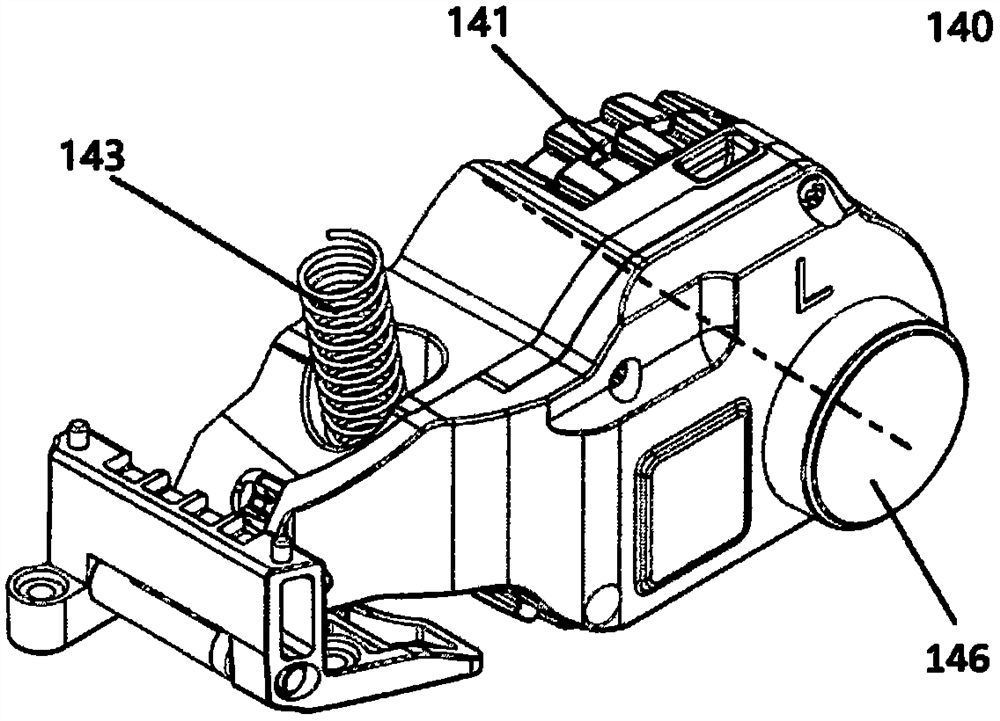

[0060] Figure 1-2 is a schematic structural view of an automatic cleaning device shown according to an exemplary embodiment, such as Figure 1-2 As shown, the automatic cleaning equipment can be a vacuum cleaning robot, a floor mopping / scrubbing robot, or a window climbing robot, etc. The automatic cleaning equipment can include a mobile platform 100, a perception system 120, a control system 130, a drive System 140 , cleaning module 150 , energy system 160 and human-computer interaction system 170 . in:

[0061] The mobile platform 100 may be configured to automatically move in a target direction on the operating surface. The operation surface may be the surface to be cleaned by the automatic cleaning equipment. In some embodiments, the automatic cleaning equipment can be a mopping robot, and the automatic cleaning equipment works on the ground, and the ground is the operating surface; the automatic cleaning equipment can also be a window cleaning robot, and the automatic...

Embodiment 2

[0147] According to specific embodiments of the present invention, such as Figure 9 As shown, the present invention provides an automatic cleaning device. This embodiment has the same structure as the above embodiment and has the same function or effect, which will not be repeated here. Specifically, the automatic cleaning equipment includes a mobile platform 100 configured to automatically move on the operating surface; a cleaning module 150 set on the mobile platform 100, including: a dry cleaning module 151 configured to use a dry Clean at least a part of the operating surface in a wet cleaning manner; the wet cleaning module 400 is configured to clean at least a part of the operating surface in a wet cleaning manner; wherein, the wet cleaning module 400 includes: for cleaning the The cleaning head 410 on the operation surface, the driving unit 420 used to drive the cleaning head 410 to reciprocate along the target surface, the target surface is a part of the operation sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com