Device for adjusting girdling depth of wire body by wire stripper

A technology of adjusting device and wire stripper, applied in cable installation, cable installation device, equipment for dismantling/armoring cables, etc., can solve the problems of fixing and adjusting the depth of cutting, difficult to cut cables, and copper wire damage. , to achieve the effect of increasing circumferential fixation and increasing fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

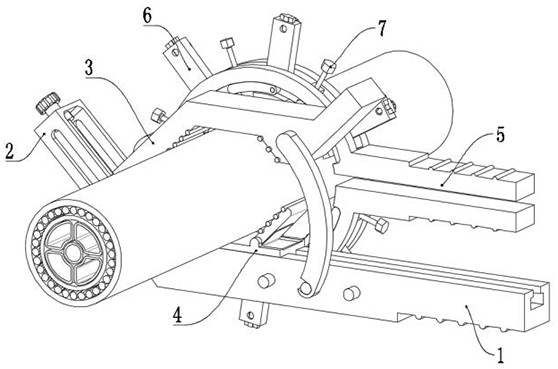

[0030] Example: as attached figure 1 to attach Figure 11 As shown: the present invention provides a device for adjusting the cutting depth of the wire body by wire strippers, including an installation device 1; an installation device 1, a control structure 2 is arranged at the end of the installation device 1, and a clamping assembly 3 is arranged in the control structure 2 , the upper end of the installation device 1 is slidably installed with a fastening device 4 .

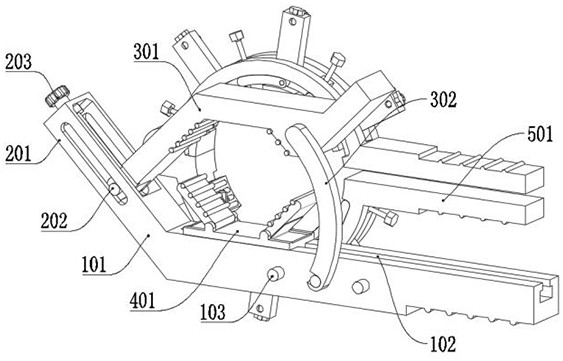

[0031] Wherein, the installation device 1 includes: an installation rod 101, the left end of the installation rod 101 is set to a 45-degree upward tilted structure, and the left end of the installation rod 101 is set to an inclined upward structure, which facilitates the setting of the control structure 2 With the installation of the clamping assembly 3, the upper end surface of the mounting rod 101 is provided with a mounting groove 102, and the mounting groove 102 provided on the mounting rod 101 is conduciv...

Embodiment 2

[0036] Embodiment 2: outer ring structure 5, the outer ring structure 5 is a symmetrical structure up and down, a cutting structure 6 is slidably installed on the outer ring structure 5, and an adjusting structure 7 is arranged on the outer ring structure 5; the cutting structure 6 includes: an inner sliding Block 601, the inner slider 601 is a long plate structure, the inner slider 601 is a hollow structure, the top outer wall of the inner slider 601 is screwed with bolts, and the inner slider 601 is slidably installed in the slot of the mounting frame 502; cutting block 602, the top of the cutting block 602 is a slat structure, and the bottom of the cutting block 602 is a right-angled cutter head. By cutting the right-angled cutter head at the bottom of the cutting block 602, it is beneficial to the cutting of the cable, and the armor in the cable can also be cut Layer cutting, the slats on the top of the cutting block 602 coincide with the inner cavity of the inner slider 60...

no. 3 example

[0041] Third embodiment: the end of the mounting rod 101 on the installation device 1 is provided with an anti-slip structure and a groove, and the handle position of the mounting frame 502 is also provided with a groove and an anti-slip structure. The anti-slip structure here can be conveniently held and pressurized. At the same time, when some relatively hard cables are cut or the armor layer is directly cut, the groove position of the installation rod 101 and the installation frame 502 can be directly connected to the booster rod, so as to facilitate the application of pressure on the installation rod 101 and the installation frame 502 The effect makes the subsequent ring cutting of the cable more labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com