Bridge pier inner wall defect detection equipment and method

A defect detection and pier technology, which is applied in the direction of optical defect/defect detection, measuring device, material analysis through optical means, etc. It can solve the problems of different diameters of the internal space of pier, uncertain manual detection method, unclear light of hollow pier, etc. , to achieve the effect of simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

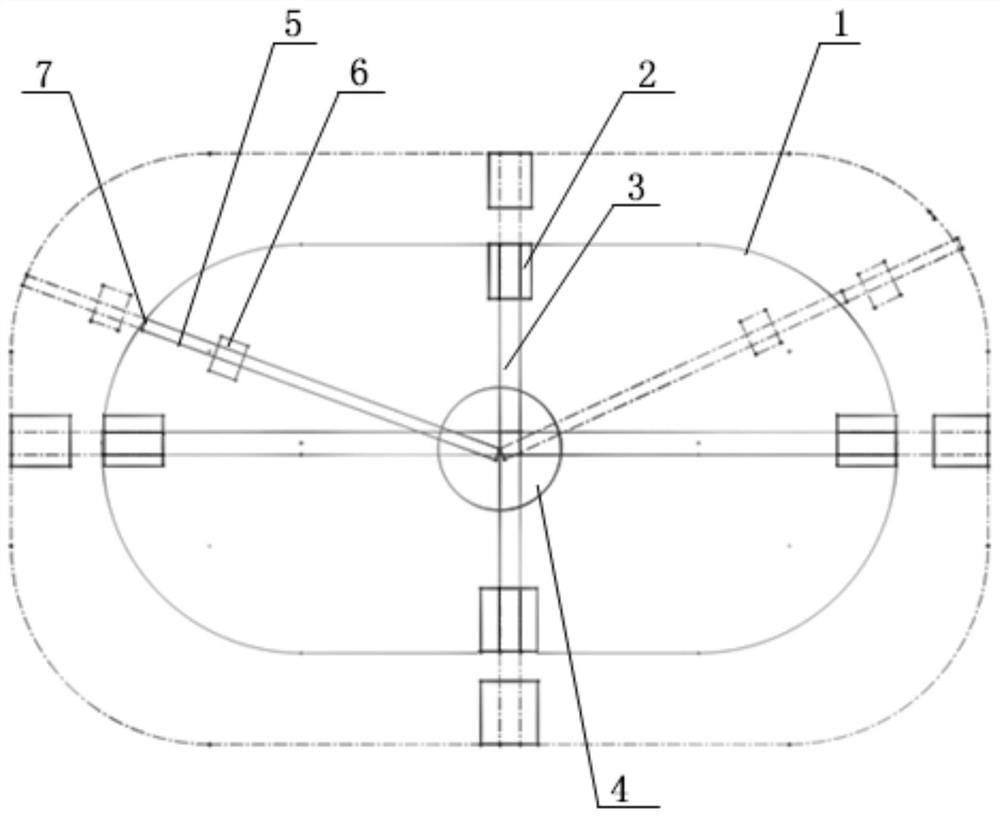

[0032] as attached figure 1 As shown in the figure, it is a structural schematic diagram of a top view of a bridge pier inner wall defect detection device provided in this embodiment. The device includes a motion control assembly 4, four telescopic support rods 3 are arranged on the outside of the motion control assembly 4, and rollers 2 are arranged on the outer ends of the telescopic support rods 3, and the rollers 2 are always attached to the inner wall 1 of the pier, and maintain The frictional force enables the whole device to slide up and down stably on the inner wall of the pier. The motion control component 4 communicates with the control center and receives work instructions from the control center to perform tasks.

[0033] An electric cylinder is arranged inside the telescopic support rod 3, and when subjected to the force of the inner wall 1 of the bridge pier, the electric cylinder will generate a pressing force of the same size to ensure that the telescopic supp...

Embodiment 2

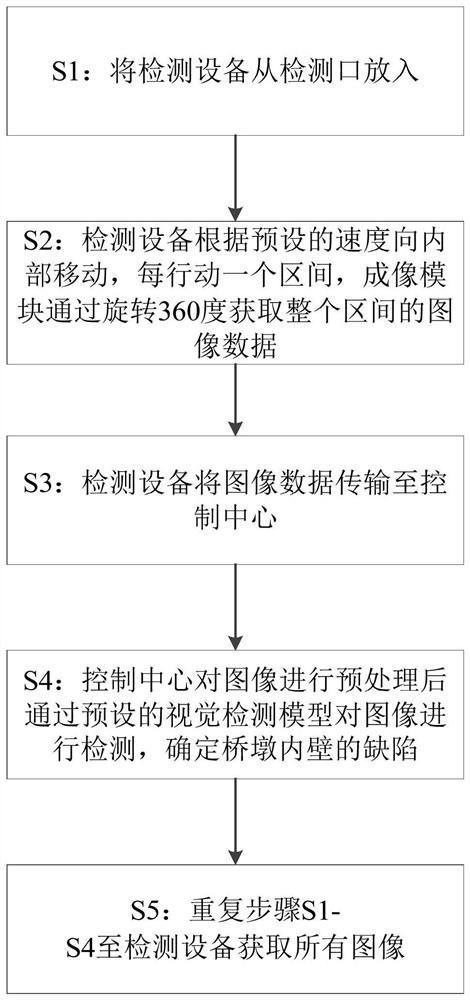

[0040] as attached image 3 As shown, it is a flow chart of a method for detecting defects on the inner wall of a bridge pier provided in this embodiment, and the method specifically includes:

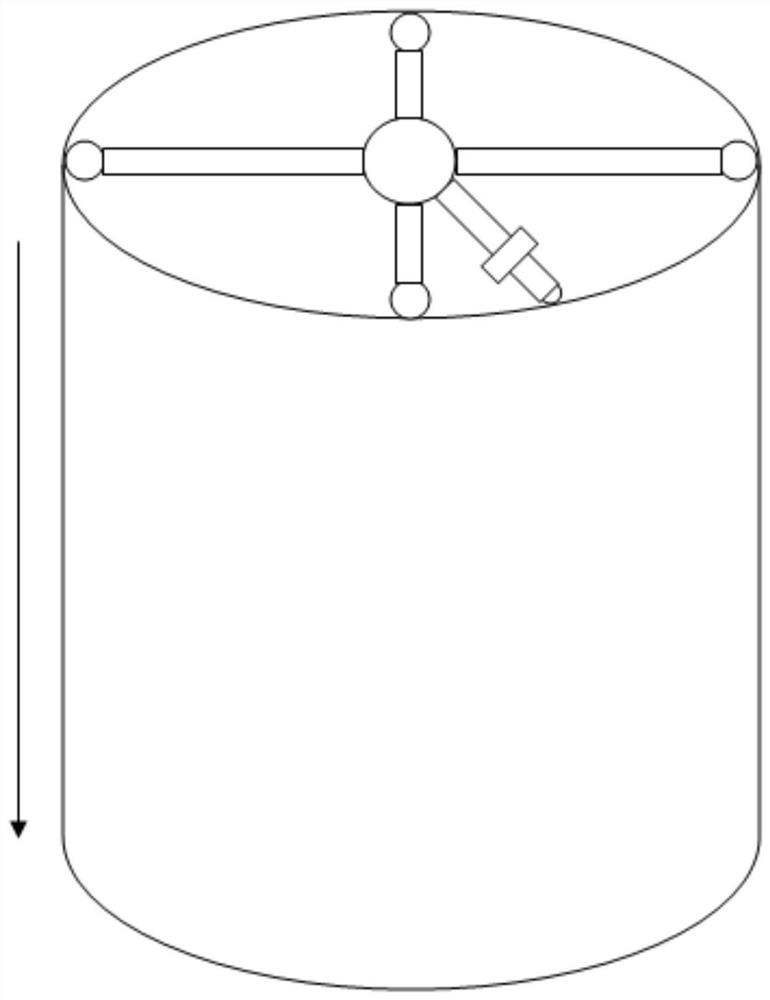

[0041]Step 1: Put the detection device into the detection port, and the whole device will automatically move to the inside. Every time a section is moved, the imaging component will perform a 360-degree data collection. The motion control component of the detection equipment executes the task after receiving the command from the control center. as attached figure 2 As shown, it is a schematic diagram of the working principle of the pier inner wall defect detection equipment used in the bridge pier inner wall defect detection method provided in this embodiment. The equipment enters from the entrance of the pier, moves downward and acquires image data, and moves downward when the equipment moves During the process, the imaging component rotates 360 degrees following the telescopic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com