Truck hub bearing mud durability testing machine

A wheel bearing and durability test technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of reduced detection effect, unreliable detection results, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

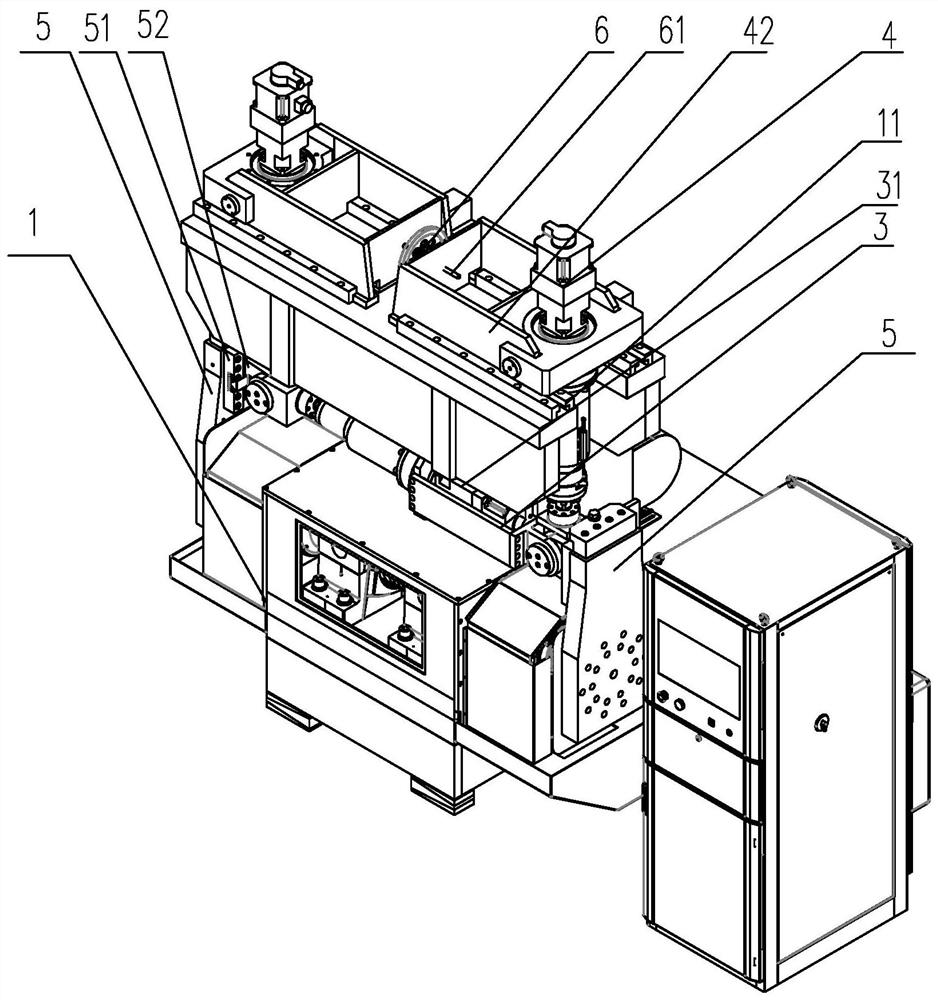

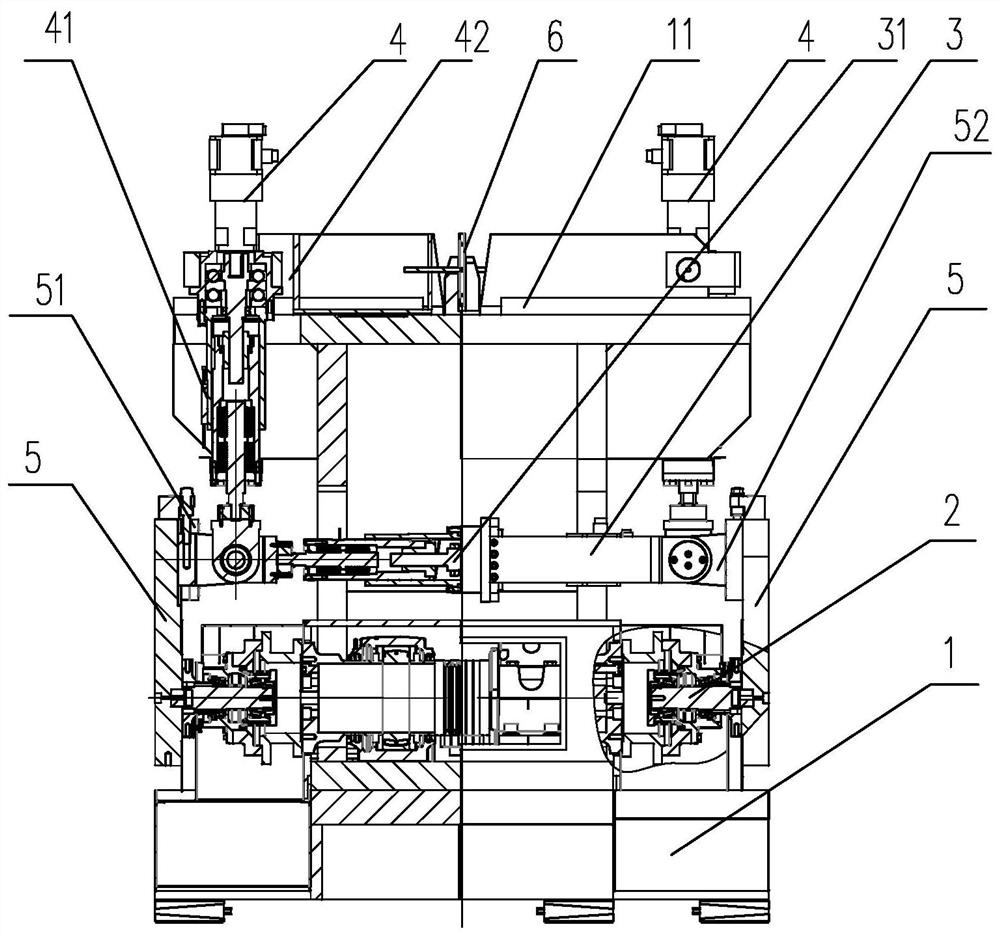

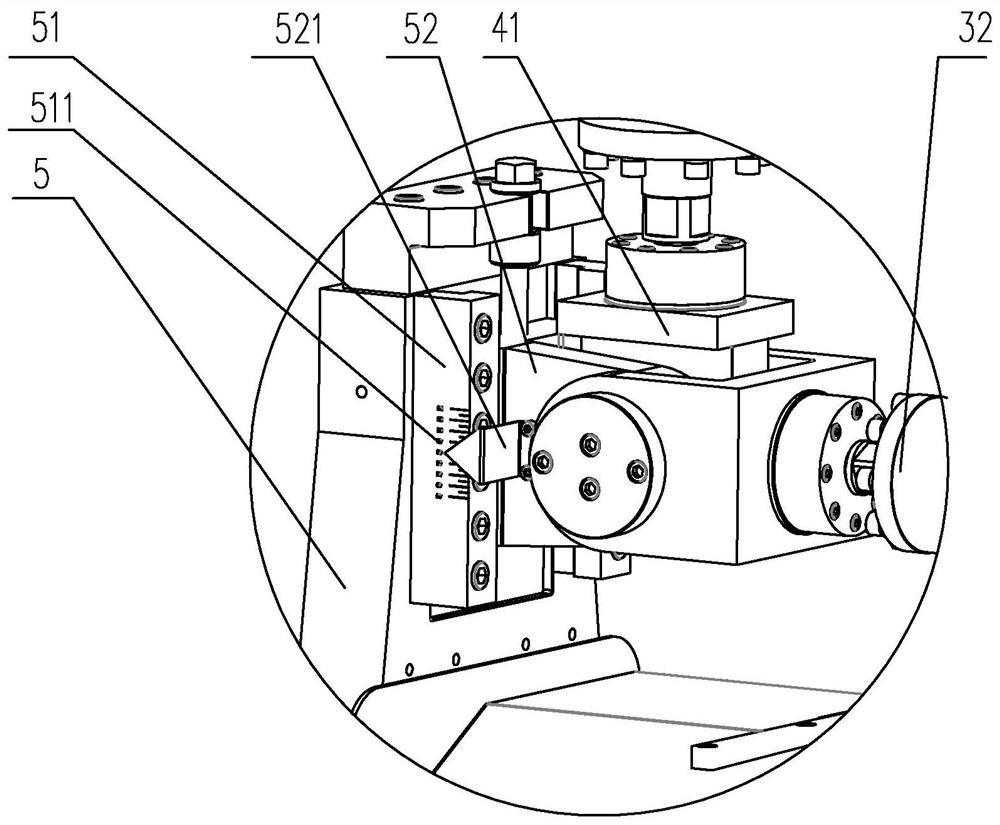

[0024] Embodiment of truck hub bearing mud durability testing machine of the present invention is for example Figure 1 to Figure 4 As shown: it includes a frame 1, the frame 1 is provided with a test shaft 2 along the length direction, and the position corresponding to the test shaft 2 on the frame 1 is also provided with a driving member for driving the test shaft 2 to rotate. The two ends of the shaft 2 are respectively provided with accommodating grooves for accommodating and installing the hub bearing to be tested, and the two ends of the test shaft 2 are respectively connected with side plates 5, and the side plates 5 are provided with positioning seats 52, and the positioning The seat 52 is set higher than the test axis 2, and an axial load loading mechanism is arranged between the positioning seats 52 on the two side plates 5, and a radial loading cylinder 4 is also provided on the frame 1, and the radial loading cylinder 4 corresponds to The position of the accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com