Locking nut

A technology for locking nuts and internal threads, which is applied in the direction of nuts, locking fasteners, screws, etc., and can solve problems such as unfavorable engine connection, nuts are easy to be loosened by vibration, and engine safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

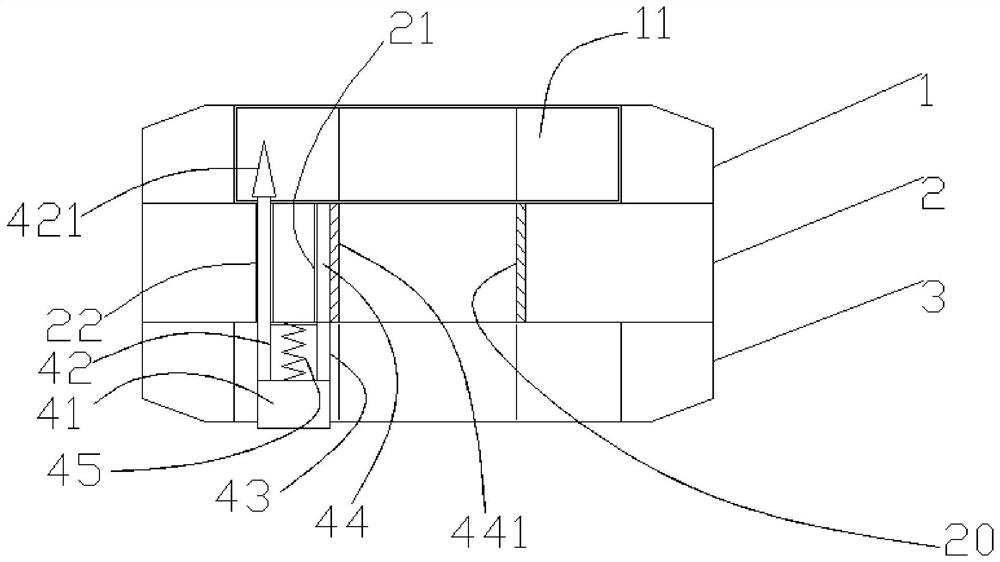

[0016] refer to figure 1 , a lock nut, including a first hexagonal tube 1, a second hexagonal tube 2, a first internal thread 20, a chute 21, a through hole 22, a third hexagonal tube 3, a ring 41, a first straight Rod 42, limit pin 421, first arc-shaped plate 43, second arc-shaped plate 44, second internal thread 441, spring 45, the upper end surface of the second hexagonal tube 2 is provided with coaxial first six Angular tube 1, the lower end surface of the second hexagonal tube 2 is provided with the third coaxial hexagonal tube 3, the lower end surface of the first hexagonal tube 1 is parallel and symmetrical to the upper end surface of the third hexagonal tube 3, the second six The internal diameter of angle tube 2 is less than the internal diameter of the first hexagonal tube 1, the 3rd hexagonal tube 3, the inner tube wall of the second hexagonal tube 2 is provided with the first internal thread 20, and the upper part of the second hexagonal tube 2 is provided with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com