TBM tunneling optimization method based on rock slag physical characteristics

A technology of physical characteristics and optimization methods, which is applied in the fields of earth drilling, biological models, color/spectral characteristics measurement, etc., can solve the problems of hob wear, large influence, and inability to provide timely feedback during TBM dynamic excavation process, so as to improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

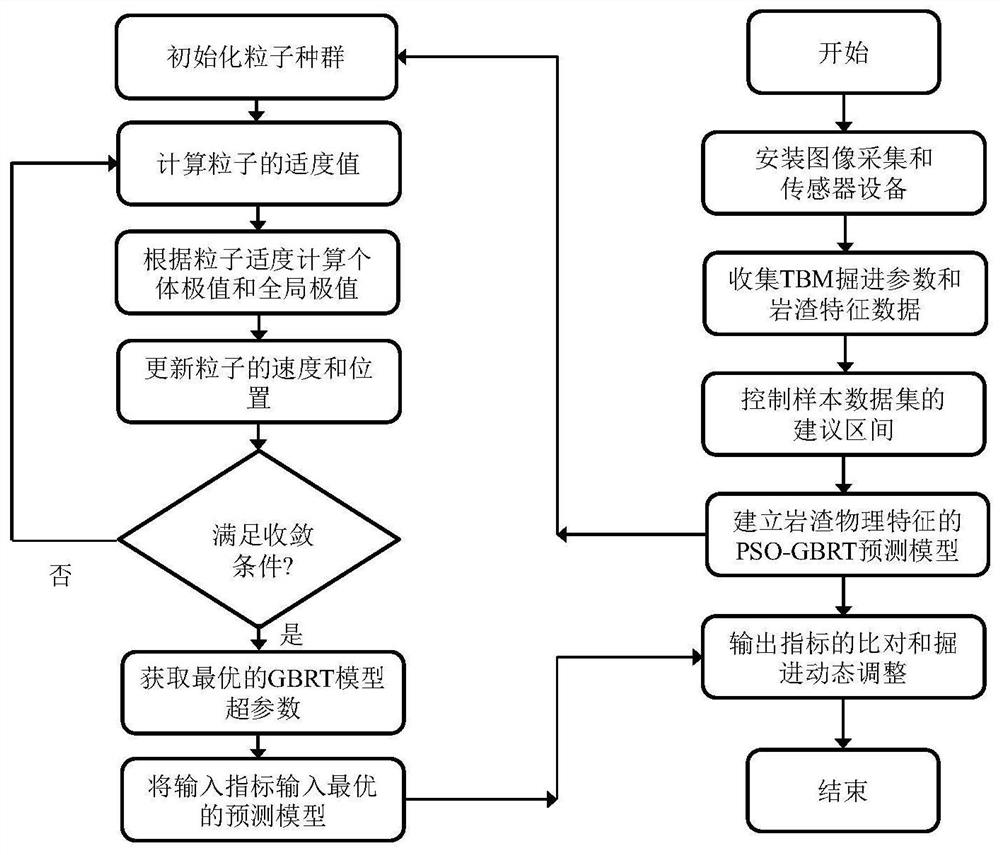

[0045] Embodiment, comprises the following steps:

[0046] (1) Information collection equipment installation

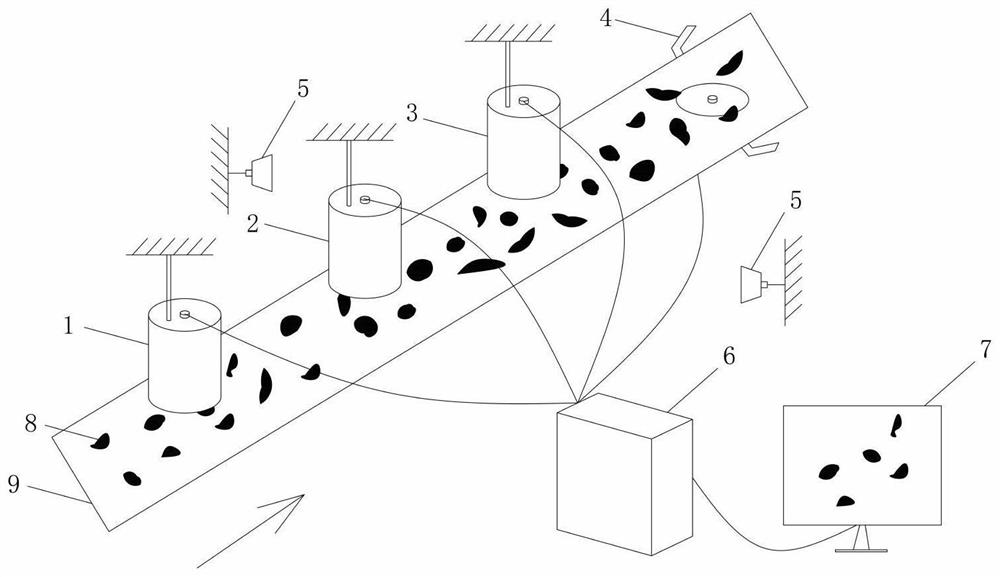

[0047] The automatic collection and analysis system for the physical characteristics of TBM excavated rock slag according to the embodiment of the present invention includes: an industrial camera, an infrared thermal imager, a hyperspectral imager, and a load cell, such as figure 2 As shown, install information collection equipment on the conveyor belt in sequence along the slag discharge direction of the arrow, and use LED supplementary light to compensate the rock slag on the slag discharge belt.

[0048] (2) Data collection and processing

[0049] The industrial camera collects the two-dimensional image information of rock slag, automatically recognizes the acquired rock slag image information, and obtains the shape and geometric characteristics of rock slag after image processing of rock slag. Rock residue image processing includes converting the collected rock...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com