Crawler bed structure with flushing and cleaning functions

A crawler and functional technology, applied in the field of material conveying equipment, can solve the problems of consuming a lot of manpower, affecting the production efficiency of factory equipment, and poor cleaning effect, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

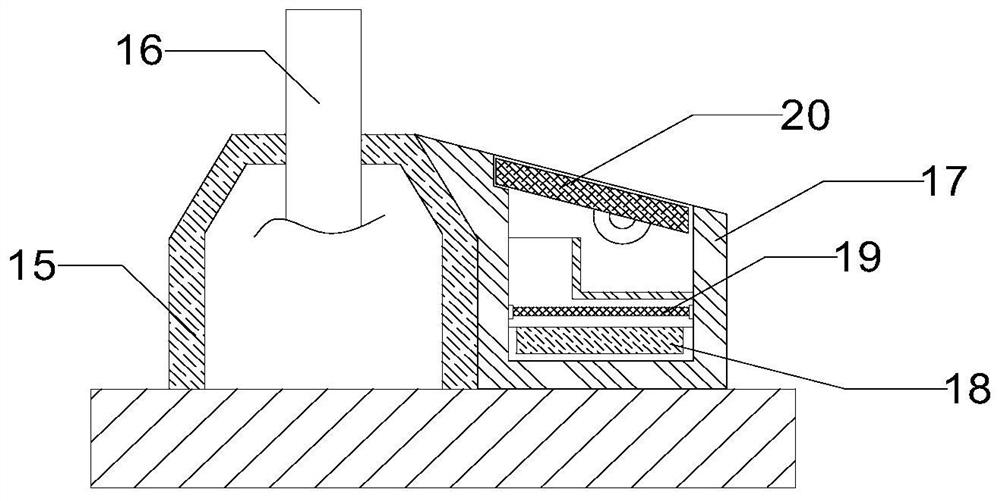

[0025] see Figure 1-5 , in an embodiment of the present invention, a crawler bed structure with flushing and cleaning functions includes a conveyor frame 1, one end of the conveyor frame 1 is rotatably connected with a driving roller 2, and a drive motor 3 is fixedly installed on the top of the conveyor frame 1, and the drive motor The output end of 3 is connected to the driving roller 2 through a belt, and the inner wall of the conveyor frame 1 is connected with several driven rollers 4, and the outer wall of the driving roller 2 is driven by the material conveyor belt 5 and several driven rollers 4. connected, the surface of the material conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com