Manual knurling conveying line

A conveyor line and manual rolling technology, applied in the field of knurling, can solve the problems of complicated structure and inconvenient use by users, and achieve the effects of convenient use, guaranteed accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

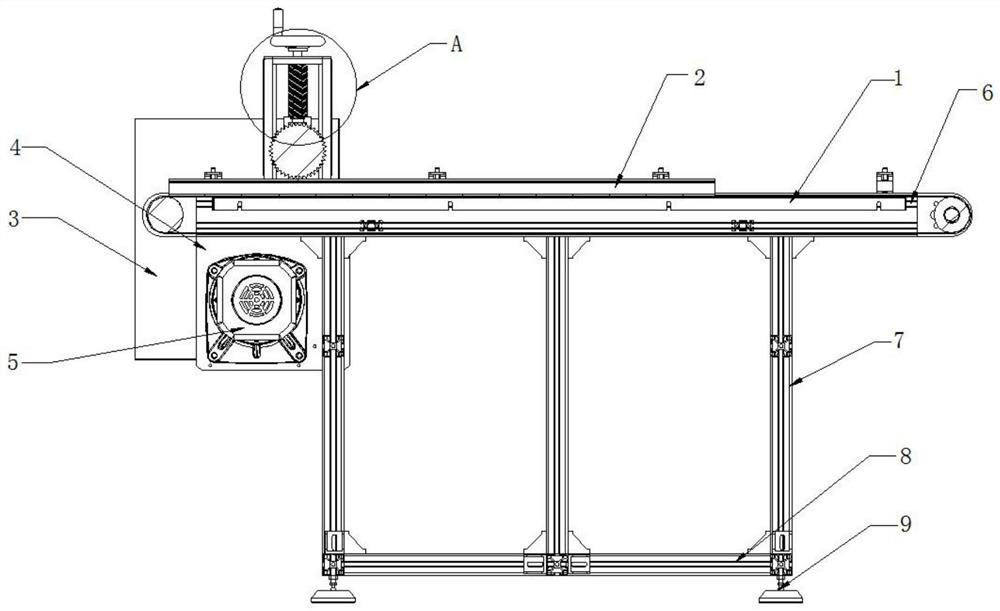

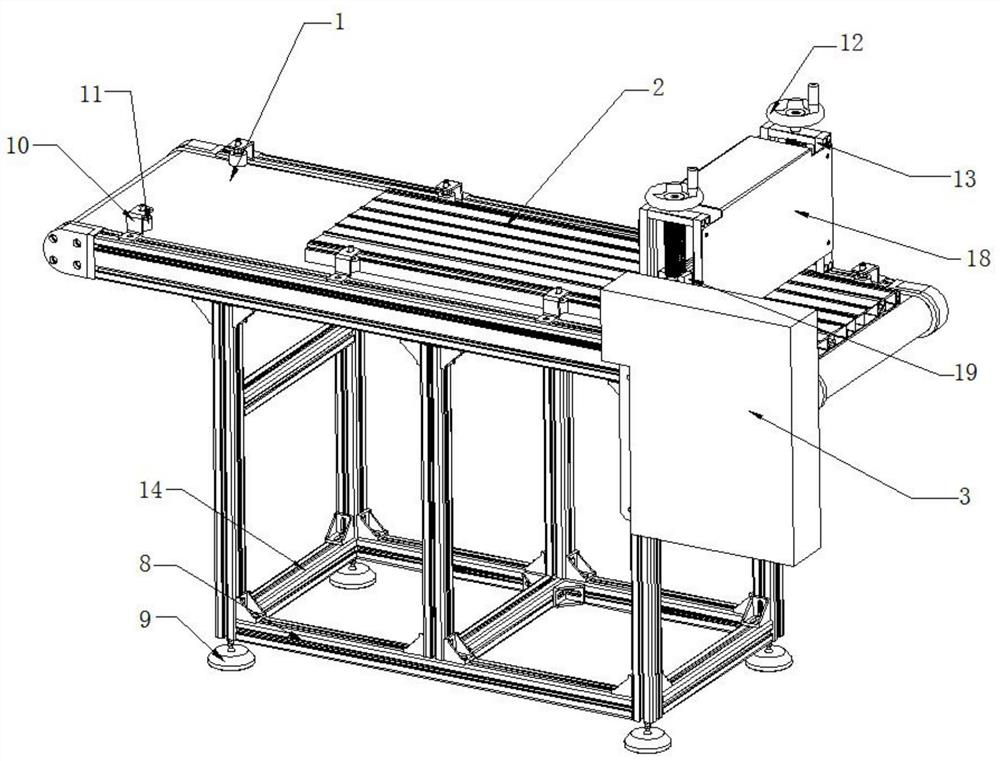

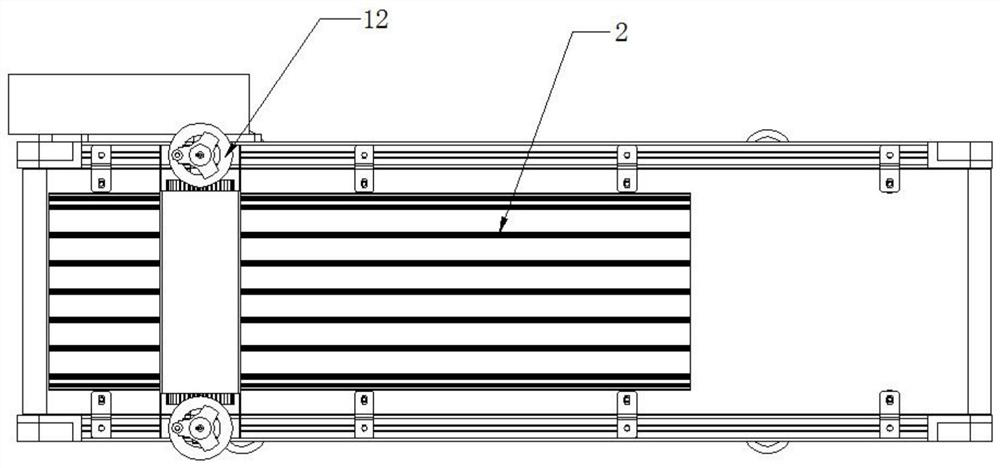

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a manual knurling conveyor line, including a conveyor line 1, a profile body 2, a joint frame 3, a placement frame 4, a motor 5, a conveyor chain 6, a support column 7, a horizontal plate 8, and a base 9 , mounting plate 10, limit idler wheel 11, hand wheel 12, adjustment seat 13, vertical plate 14, screw rod 15, spring 16, knurled shaft 17, auxiliary frame 18, transfer block 19, the outer surface of the conveying line 1 The profile body 2 is provided, and both ends of the profile body 2 are equipped with limit idler wheels 11, and the outside of the limit idler wheel 11 is provided with a mounting plate 10, and the inside of the conveying line 1 is equipped with a transmission chain 6, and the transmission chain 6 One end of the outside is provided with a motor 5, the placing frame 4 is located outside the motor 5, the connecting frame 3 is installed outside the placing frame 4, the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com