Automatic iron sheet pasting mechanism for paper

An iron sheet, automatic technology, applied in the direction of papermaking, conveyor objects, paper/cardboard containers, etc., can solve problems such as increased defective product rate, reduced production efficiency, complex structure, etc., achieves low production cost, improves production efficiency, and simplifies The effect of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the invention.

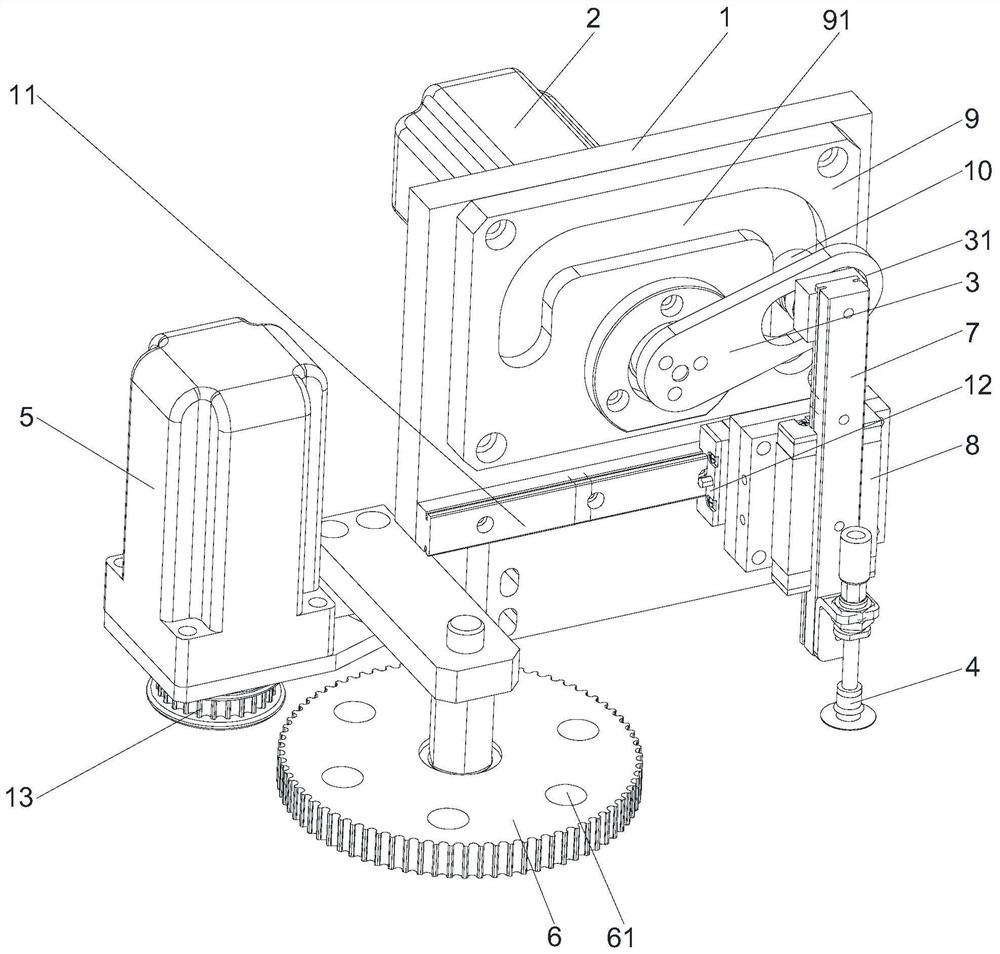

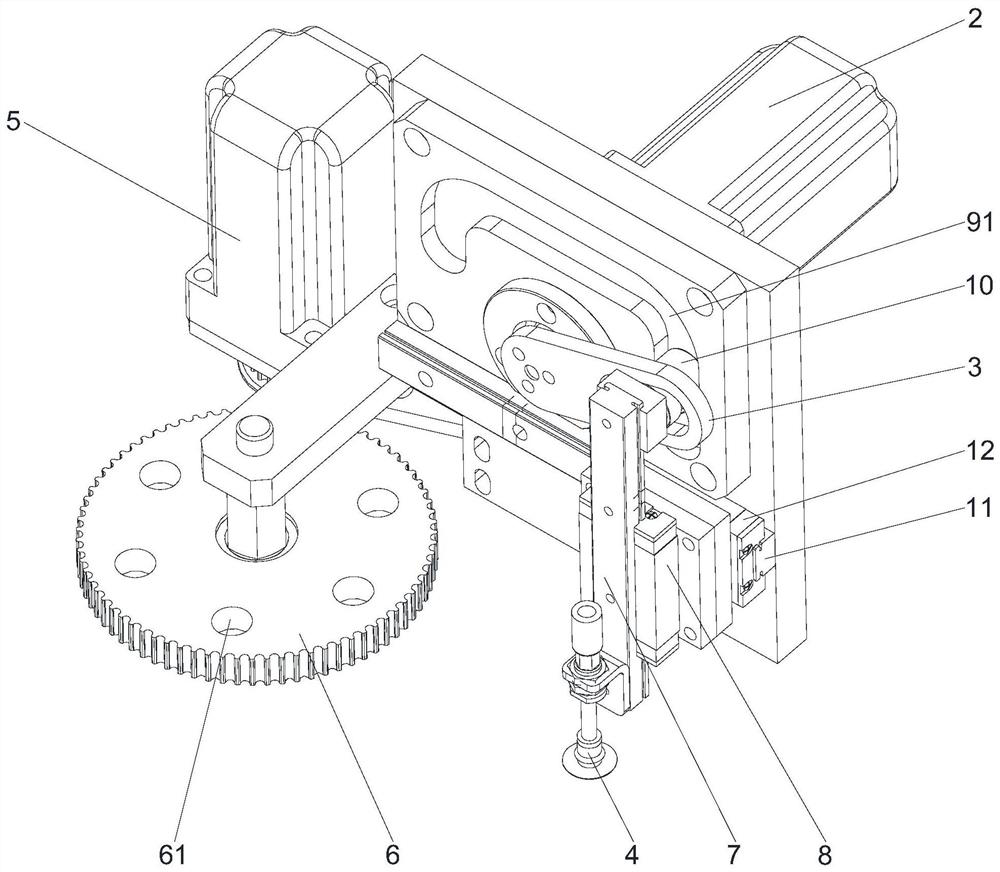

[0026] Such as figure 1 with figure 2 As shown, an automatic iron plate mechanism for paper includes a base 1, a first motor 2, a swing rod 3, a first slide rail assembly, a suction nozzle 4, a second motor 5 and a runner 6; A motor 2 is installed on the base 1 and the output shaft of the first motor 2 is connected to one end of the swing bar 3; The first slider 8 connected with the first slide rail 7; the upper end of the first slide rail 7 is movably connected with the other end of the swing rod 3, and the lower end is connected with the suction nozzle 4; the second motor 5 and the runner 6 are fixed on the base 1, and the second motor 5 is used to drive the runner 6 to rotate; on the top surface of the runner 6, there are several placement posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com