Feeding channel for plastic support preparation

A plastic support and feeding technology, applied in the field of plastic support preparation, can solve problems such as affecting product quality, damage to injection molding machines and molds, etc., and achieve the effect of ensuring normal work, ensuring quality, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

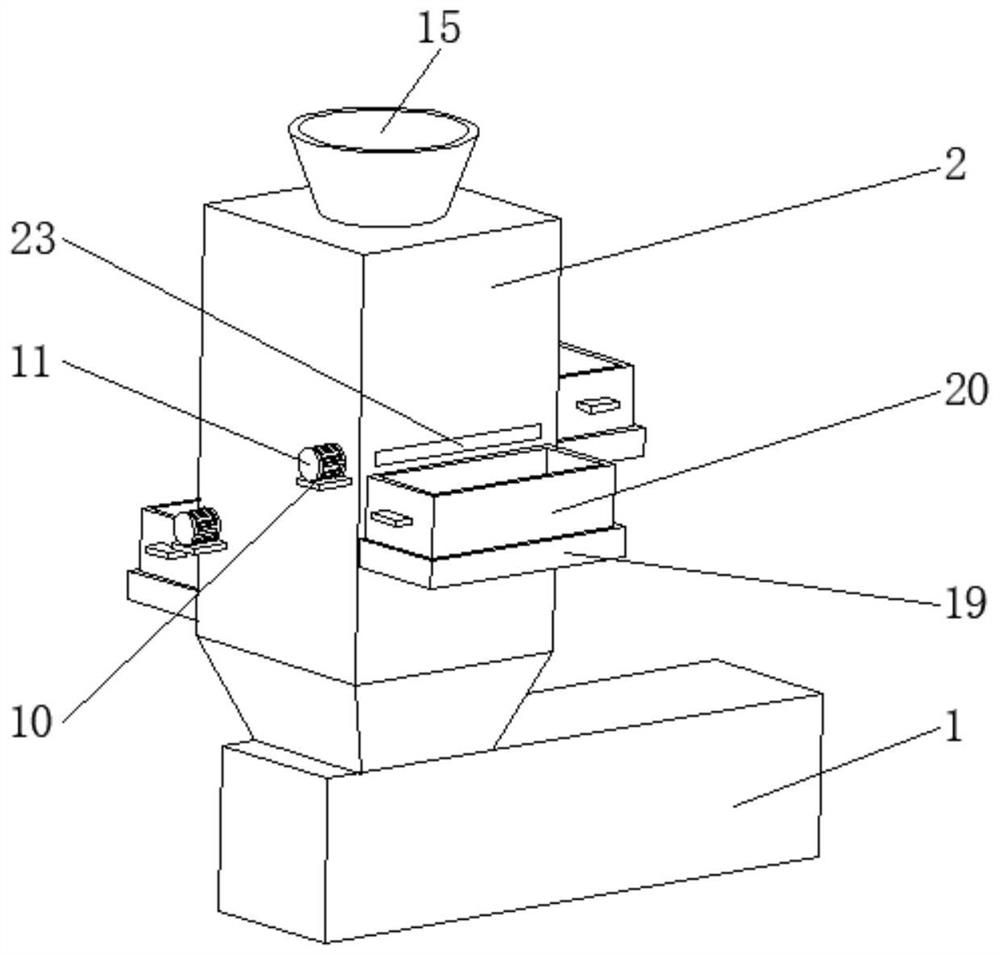

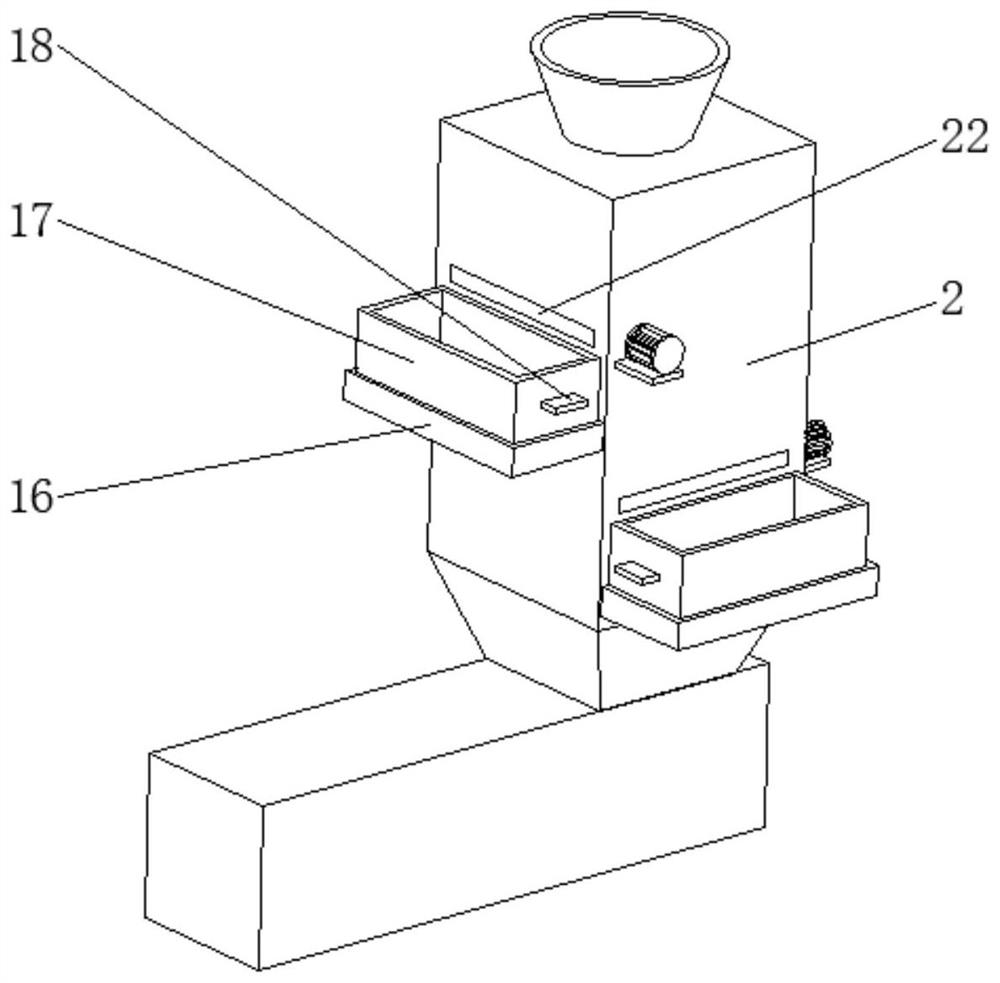

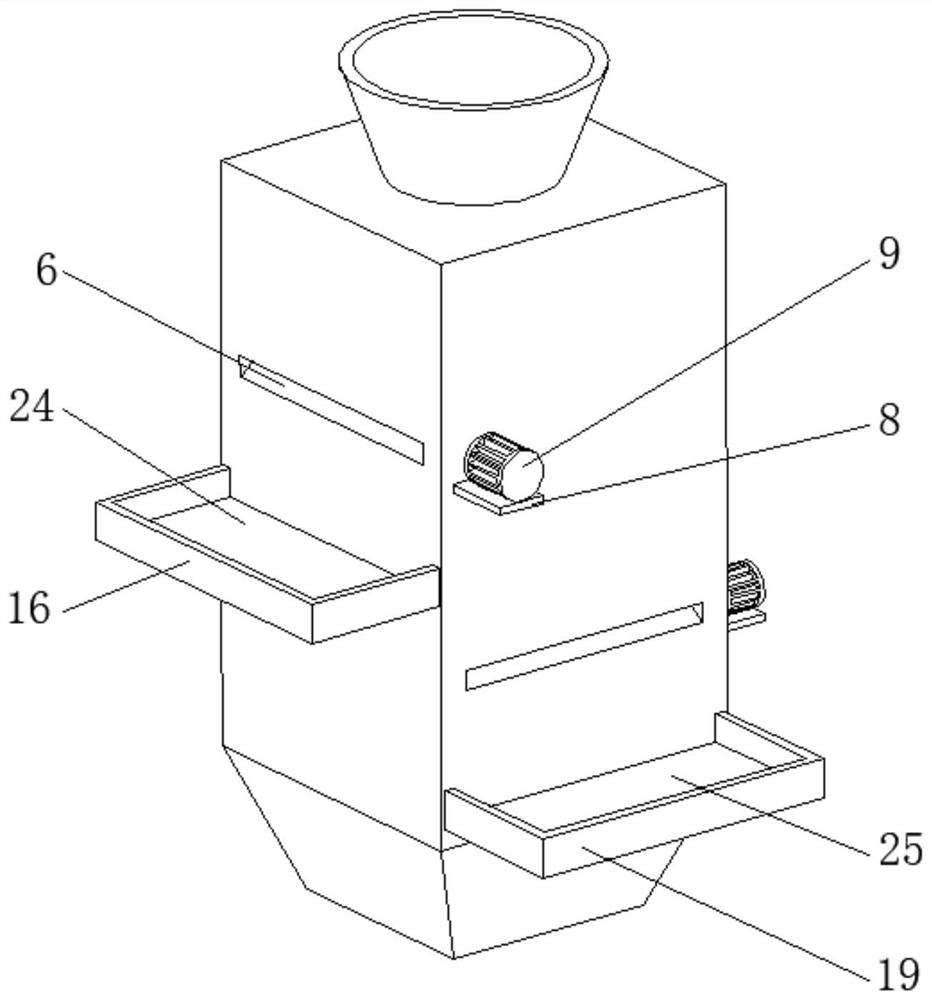

[0024] Such as Figure 1-5 As shown, the present invention provides a feeding channel prepared by a plastic bracket, including a screw feeder 1, a screen box 2 is fixedly installed on one side of the top surface of the screw feeder 1, and a feed inlet 14 is provided at the center of the top surface of the screen box 2 , the funnel 15 is fixedly installed in the feed port 14, which is convenient for inputting raw materials. The bottom surface of the sieve box 2 is provided with a discharge port 12, and the bottom surface of the sieve case 2 is all inclined to the discharge port 12 around the bottom surface. The feeding slots are connected to facilitate the screening of qualified materials to be quickly exported to the sieve box 2 and enter the screw feeder 1. There is a filter screen 3 hinged on the upper side of the inner wall of the sieve box 2. 2, a vibrator 13 is fixedly installed at the center of the bottom surface of the filter screen 3, so that the material on the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com