Pouring-size-adjustable modular pouring formwork for concrete plate manufacturing

A technology for plate making and concrete, applied in the direction of molds, etc., can solve the problems of time-consuming and labor-intensive, poor versatility, etc., and achieve the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

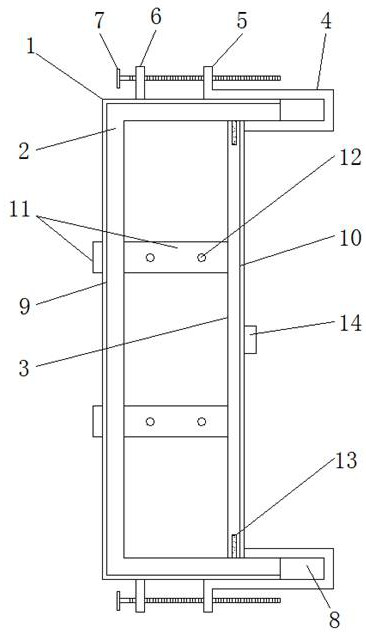

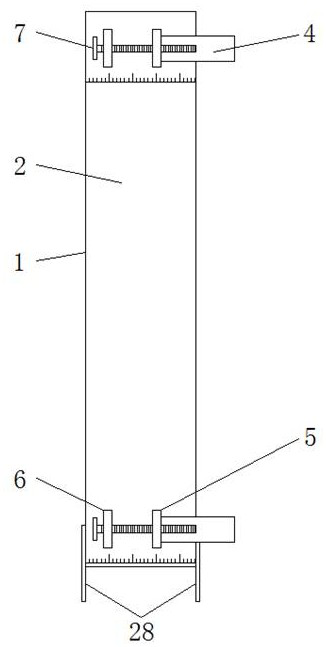

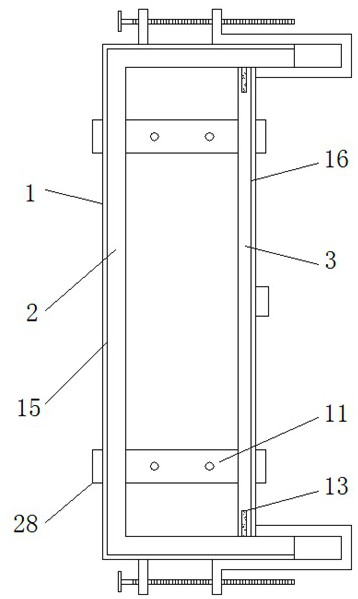

[0032] see Figure 1-8 , the present invention provides a technical solution: a modular pouring formwork for making concrete slabs with adjustable pouring size, including a pouring formwork body 1, a first pouring formwork shell 2, a second pouring formwork shell 3, a connecting frame 4, a support Frame 5, fixed plate 6, adjusting screw 7, sliding opening 8, first raised portion 9, second raised portion 10, supporting template 11, insertion hole 12, sliding opening 13, adjusting disc 14, first splicing interface 15. The second splicing interface 16, the top tight part 17, the limit groove 18, the installation port 19, the docking interface 20, the storage compartment 21, the first sealing plate 22, the second sealing plate 23, the sliding groove 24, the gear 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com