Circuit board film pasting device and method and intelligent industrial control equipment

A film sticking device and circuit board technology, applied in metal processing, printed circuits, transportation and packaging, etc., can solve the problems of reducing film supply efficiency and increasing labor intensity of workers, and achieve the effect of improving film cutting efficiency and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

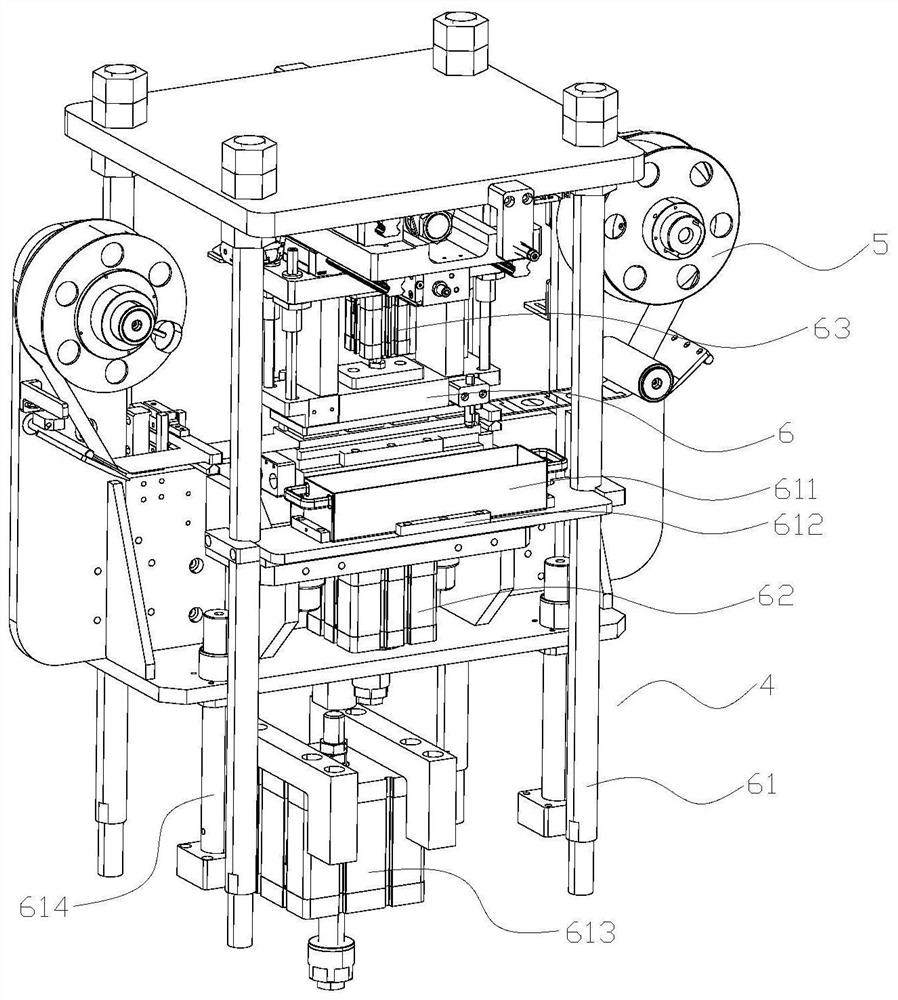

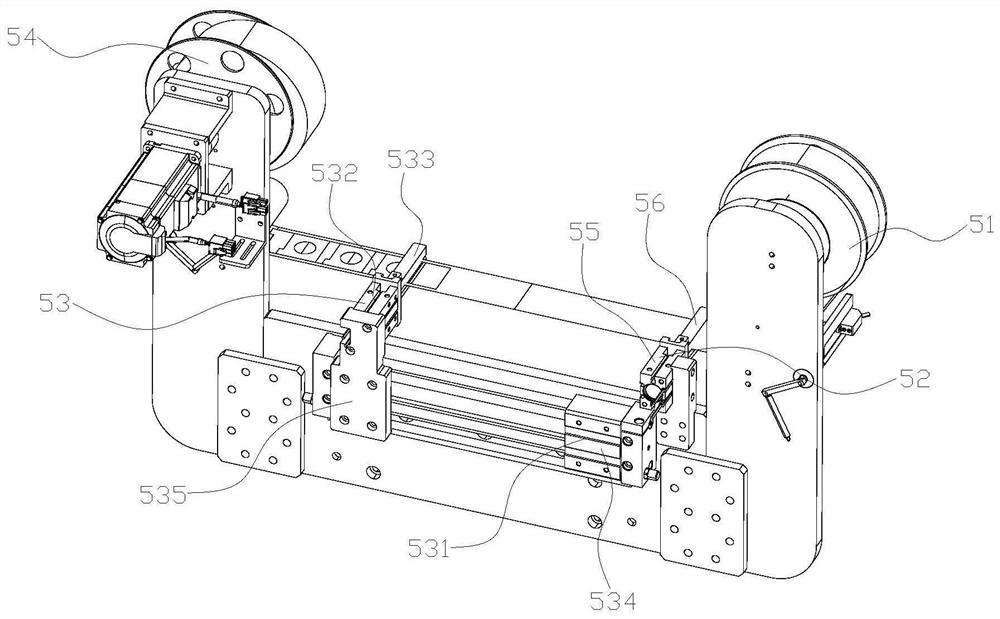

[0027] like figure 1 , image 3 As shown, the second film sticking device 4 includes a film feeding mechanism 5 and a film cutting mechanism 6; the film feeding mechanism 5 includes a feeding tray 51, a fixed clamping head 52, a movable clamping head 53 and a receiving tray 54; the fixed clamping head 52 includes a fixed cylinder 55 and a fixed head 56, the fixed cylinder 55 is fixed on the workbench, and its output end is connected with the upper and lower fixed heads 56, and the inner surface of the upper and lower fixed heads 56 is in contact with the upper and lower surfaces of the protective film; the movable clamping head 53 Including clamping head driving element 531, movable cylinder 532 and movable head 533; the driving end of clamping head driving element 531 is connected with movable cylinder 532, and the output ends of movable cylinder 532 are respectively connected with upper and lower movable heads 533, and the upper and lower The inner surface of the movable he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com