Laboratory particle screening equipment

A screening equipment and laboratory technology, which is applied in the direction of filtration, solid separation, and separation of solids from solids with airflow, can solve the problems of reducing test efficiency, crushing, and cumbersome procedures, and achieve improved detection efficiency and operation Time-saving and labor-saving, high-efficiency screening test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

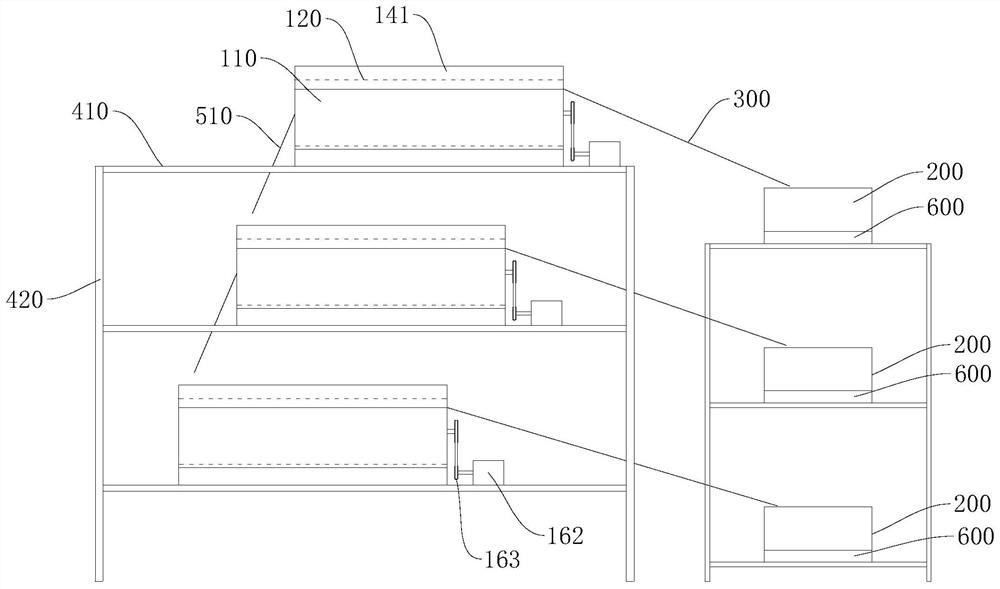

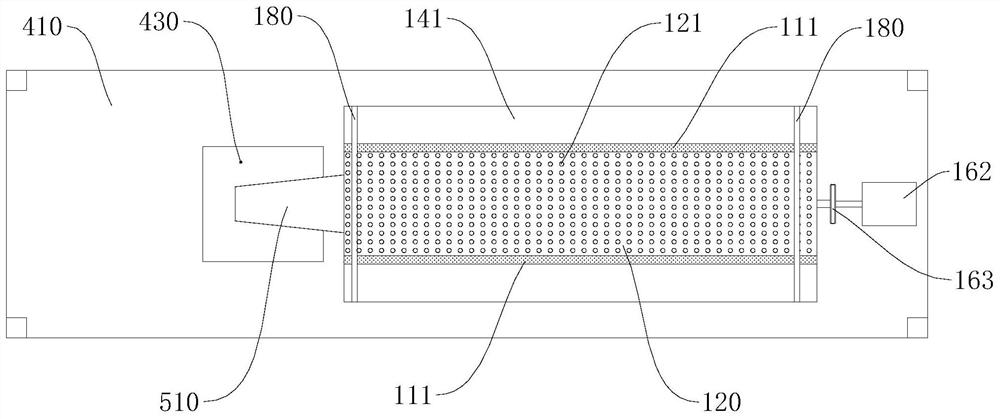

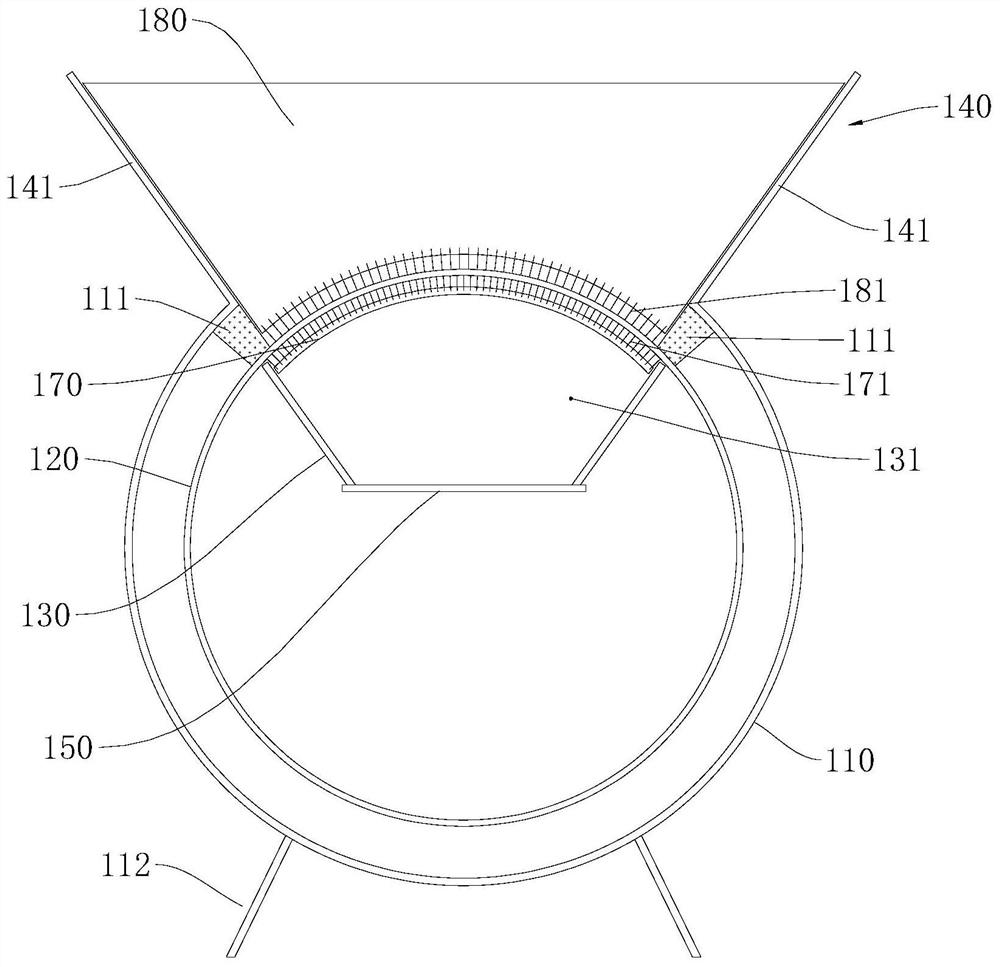

[0041] Please also refer to Figure 1 to Figure 3 , the laboratory particle sieving equipment provided by the present invention is now described. The laboratory particle screening equipment includes a joint mechanism 500, a plurality of screening units 100 distributed sequentially from top to bottom and a plurality of weighing units 600, and each screening unit 100 includes an outer cylinder 110, an inner sieve Cylinder 120, sealing member 111, hopper 140, transmission mechanism 150 and connecting mechanism 500; the axis of the outer cylinder 110 is set perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com