Sampling containing assembly, sampling pipetting head and sampling filtering device

A component and packaging technology, which is applied in the field of medical supplies, can solve problems such as easy blockage of the lotion nozzle, affect the efficiency of automation work, and the accuracy of sample volume, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

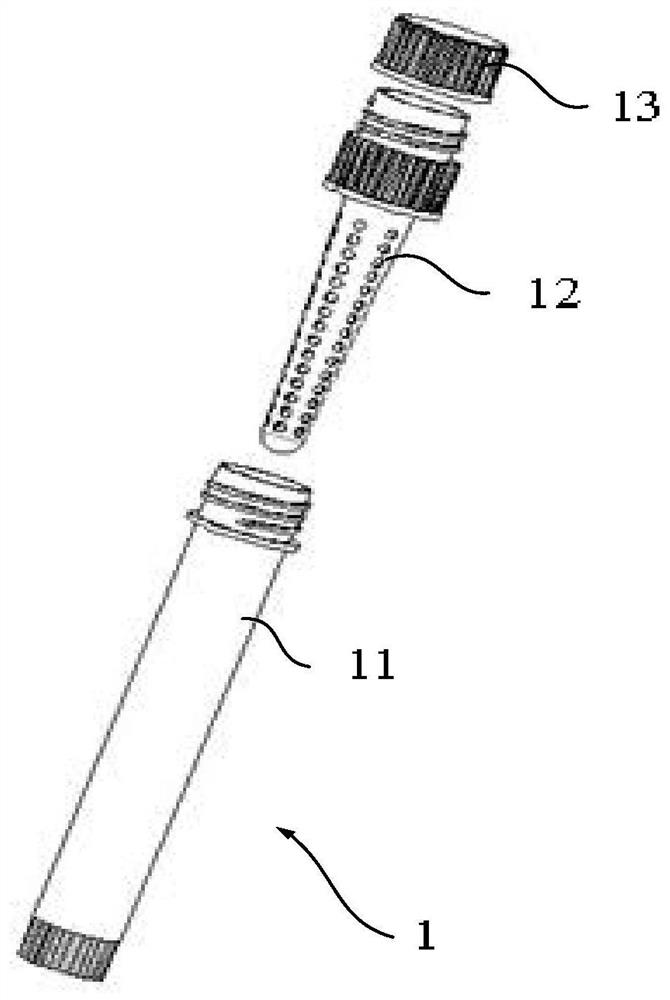

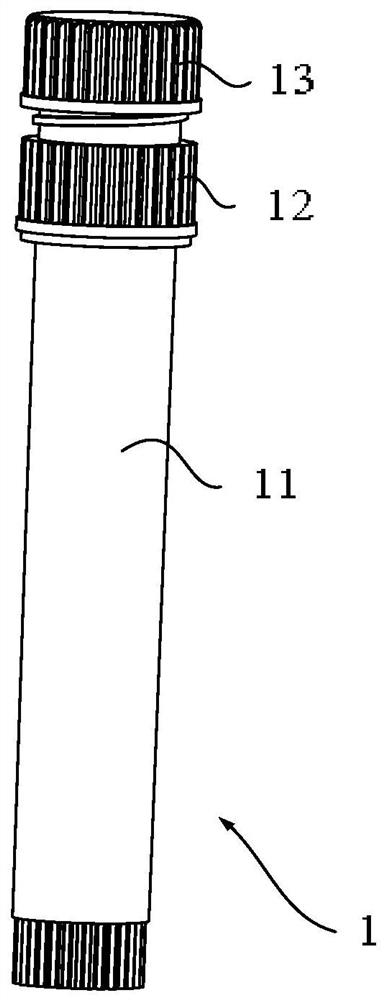

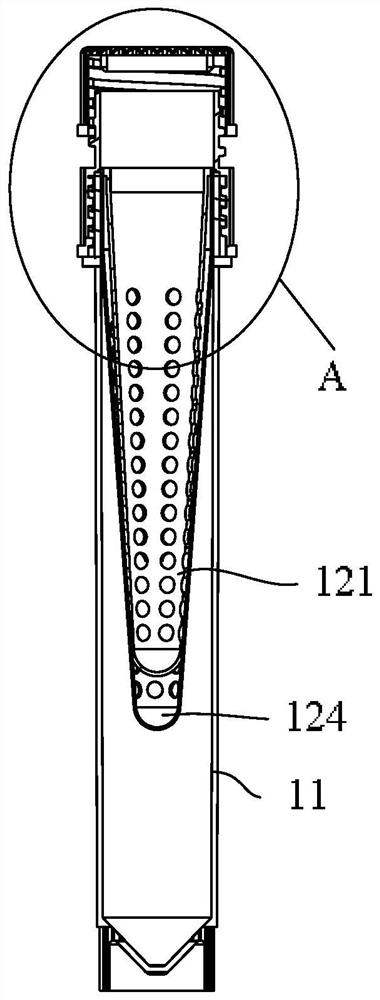

[0046] see Figure 1 to Figure 5 As shown, the embodiment of the present application provides a sampling container assembly 1, including: a sampling pipe 11 and a filter pipe 12; wherein the filter pipe 12 is arranged in the sampling pipe 11, and the filter pipe 12 is detachably connected to the sampling pipe 11 ;

[0047] The filter pipe 12 is formed with a filter hole 125 communicating with the inside of the sampling pipe 11, wherein, preferably, as image 3 and Figure 5 As shown, the filter pipe 12 has the structure of a tapered pipe, and it tapers from the open end to the bottom of the pipe.

[0048] It can be seen that due to the addition of the filter pipe 12 detachably connected to the sampling pipe 11, during use, the sampling pipe 11 can be used to contain the sample first, and then the filter pipe 12 is installed in the sampling pipe 11, and the sampling pipe 11 is filtered through the filter hole 125. The excessively large particles in the sample and the lint of...

Embodiment 2

[0058] see Figure 7 and Figure 8 As shown, the embodiment of the present application provides a sampling assembly 1, comprising: a sampling pipe 11, a filter pipe 12 and a cap 13; wherein the filter pipe 12 is arranged in the sampling pipe 11; the opening end of the filter pipe 12 forms There is an overlapping edge, and the overlapping edge is overlapped on the side wall of the opening end of the sampling pipe 11 .

[0059] The cap 13 is connected to the sampling pipe 11 through threads. Specifically, the outer wall of the sampling pipe 11 is formed with external threads, and the inner wall of the cap 13 is formed with internal threads matching the external threads.

[0060] The filter pipe 12 is formed with a filter hole 125 communicating with the inside of the sampling pipe 11 .

[0061] It can be seen that it has the same technical effect as the sampling container assembly 1 described in the first embodiment, the difference mainly lies in the structure, and the sampling...

Embodiment 3

[0063] see Figure 9 and Figure 10 As shown, the embodiment of the present application provides a sampling pipetting head 2, including: a pipetting member 21 and a filter member 22; wherein, the filter member 22 is sleeved outside the suction end of the pipetting member 21;

[0064] The filter member 22 is formed with a filter hole 125 communicating with the outside and the liquid suction end.

[0065] It can be seen that due to the addition of the filter member 22, the oversized particles and the lint of the sample with the cotton swab can be filtered out, and the pipetting member 21 will not be blocked, so as to ensure the automatic work efficiency and pipetting accuracy.

[0066] Wherein, preferably, the liquid pipetting member 21 includes a connected main pipe portion and a frustum-shaped head pipe portion.

[0067] Wherein, preferably, the filter member 22 includes a connected sleeve portion and an avoidance housing portion; wherein, the sleeve portion is tapered towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com