Combined skeleton optical cable

A combined, skeleton technology, used in optics, light guides, optical components, etc., can solve the problem of high difficulty in the production of large core number skeleton cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

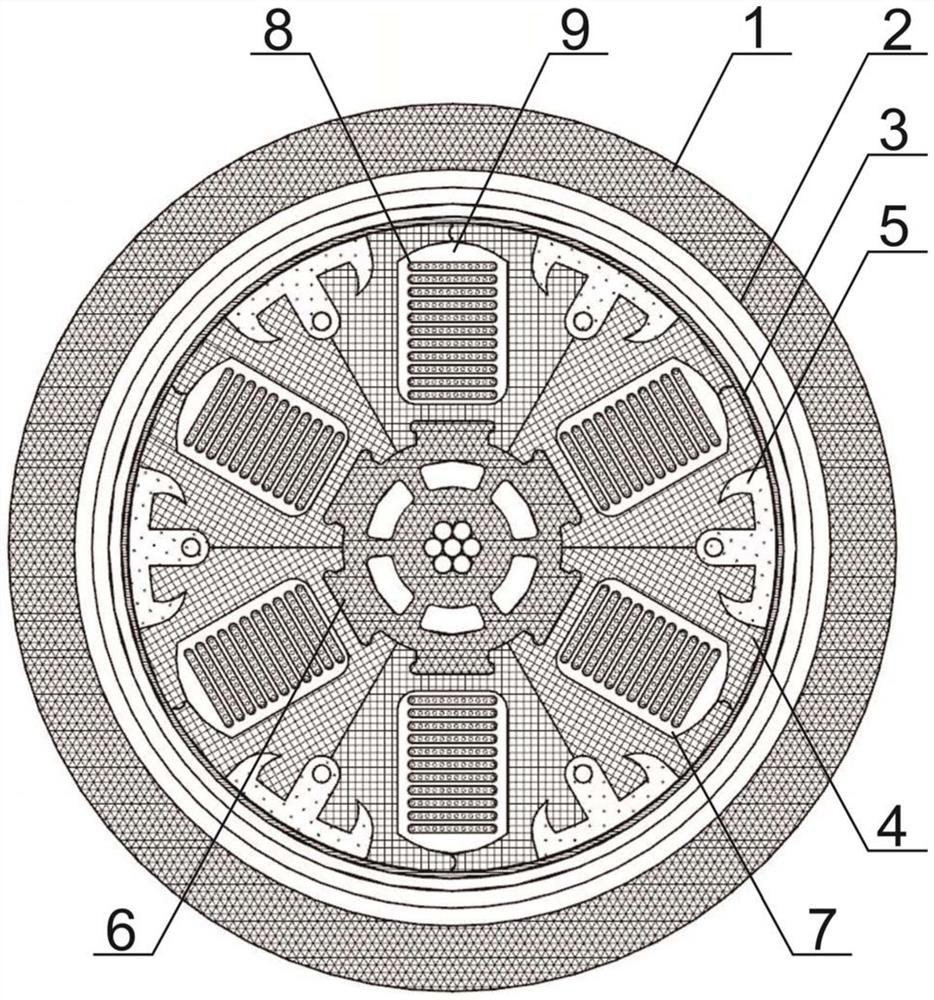

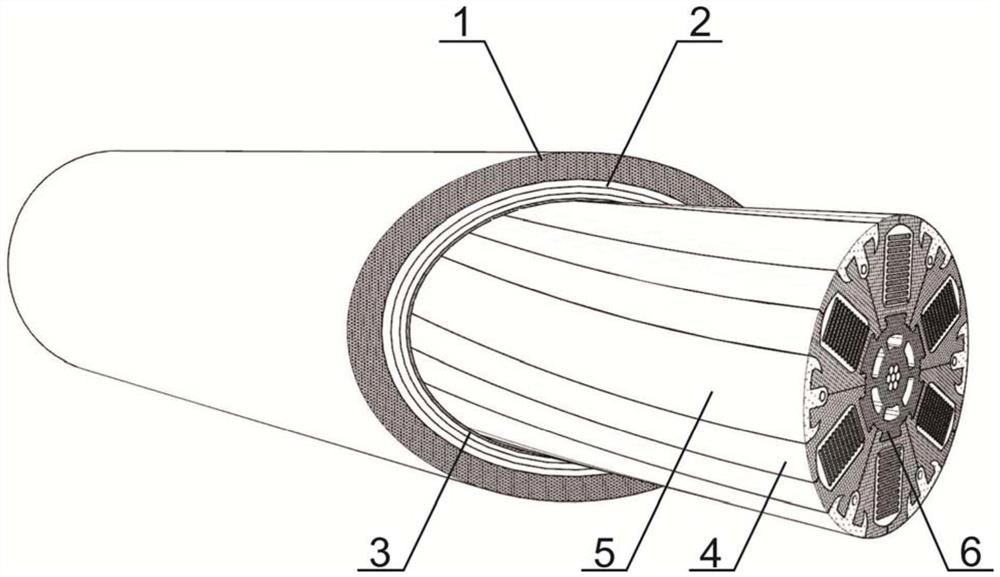

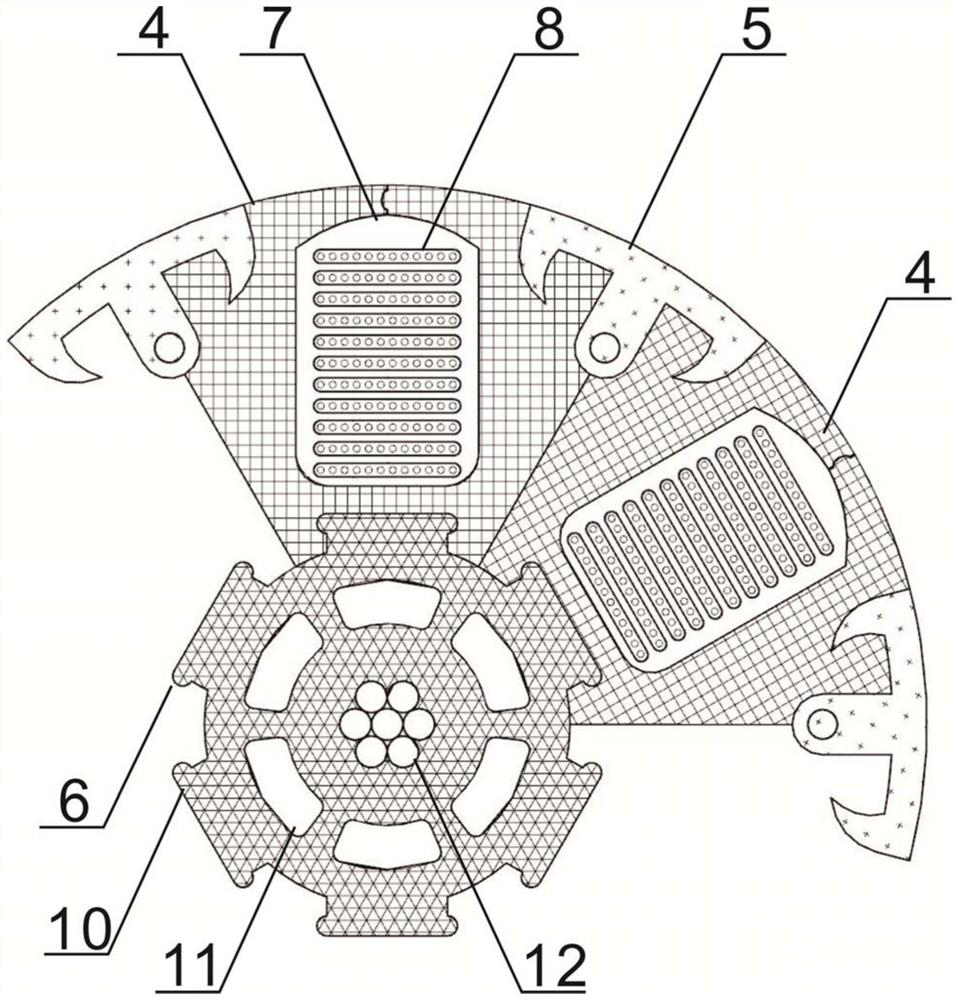

[0024] Figure 1-7 One embodiment provided by the present invention is a combined skeleton optical cable. Such as figure 1 As shown, the combined skeleton optical cable includes the outermost outer sheath 1 and the inner cable core assembly, wherein the cable core assembly is arranged in a helical twist and includes a skeleton structure and an optical fiber ribbon 8 . The combined skeleton optical cable also includes an inner cladding group 2 located between the outer sheath 1 and the cable core assembly, and the inner cladding group 2 at least includes an armor layer, a flame-retardant layer and a waterproof layer.

[0025] The focus of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com