Double-sided aspheric lens and design method thereof

A design method and aspheric surface technology, applied in the direction of lens, instrument, optics, etc., can solve problems such as complex design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

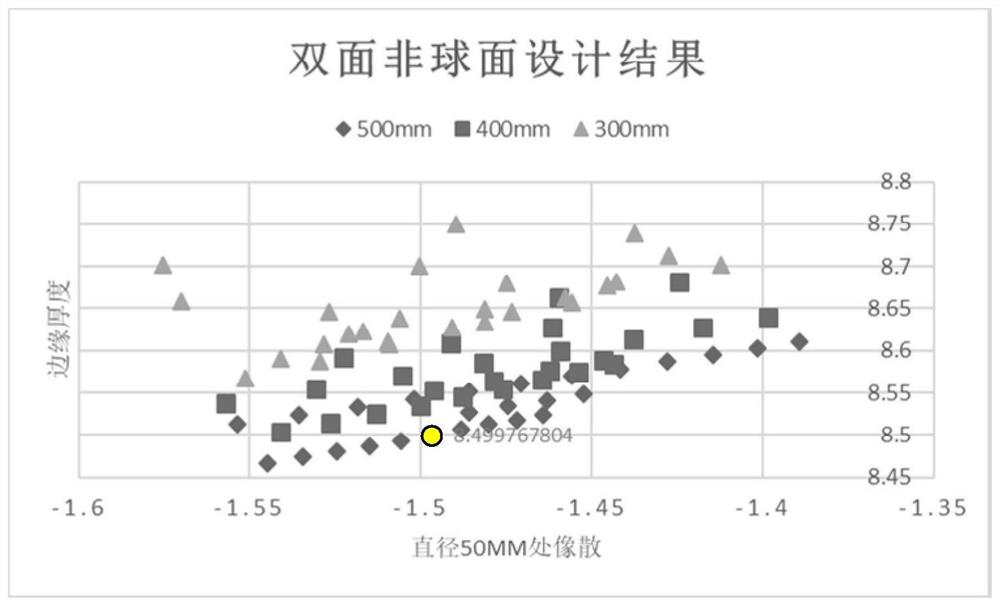

Embodiment 1

[0044] This embodiment provides a method for designing a double-sided aspheric lens, the method comprising the following steps:

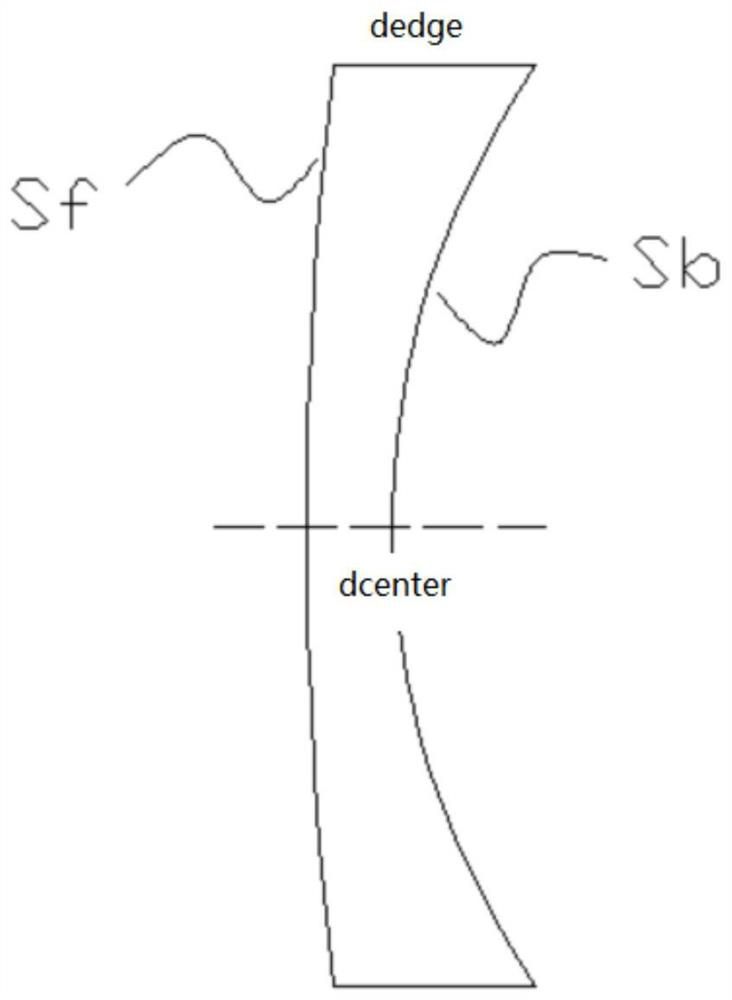

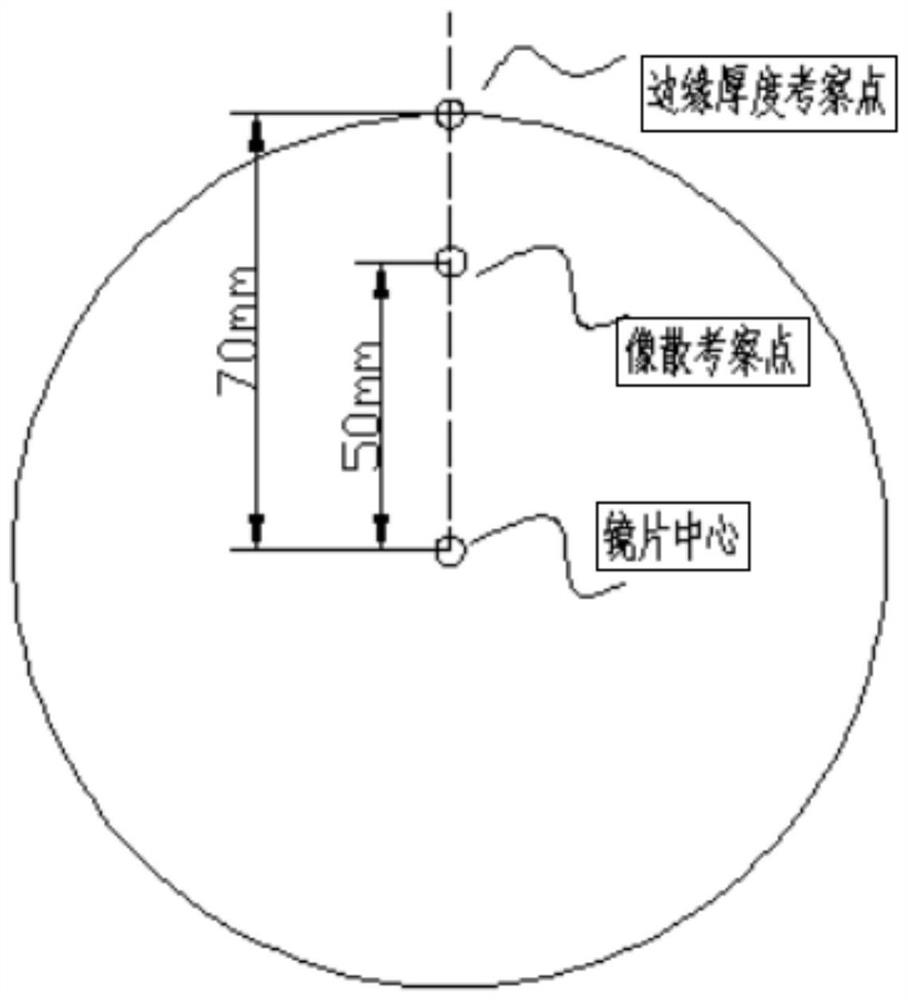

[0045] The first step, the lens surface description method

[0046] Both the front and back surfaces of the lens are described by the following cone coefficient formula:

[0047]

[0048] In the formula, Indicates the height of the surface shape, Indicates the radius of curvature of the center point, represents the distance of the evaluation point from the optical axis, and , is the conic coefficient; this requires only two variables and The shape of a surface can be determined.

[0049] The second step, design variables and

[0050] Denote the central curvature of the front surface of the lens as , the conic coefficient of the front surface of the lens is denoted as . Method of the present invention is exactly to deduce a cover calculation formula, set up variable , The relationship between the combination of the lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com