Three-dimensional inspection system and method for geometric parameters of air film holes in aeroengine blades based on zoom microscopy technology

An aero-engine and microscopy technology, which is applied in the aviation industry and can solve the problems of inability to obtain multiple parameters at the same time, low efficiency, and slow measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The specific content of the present invention will be further explained in detail below in conjunction with the embodiments.

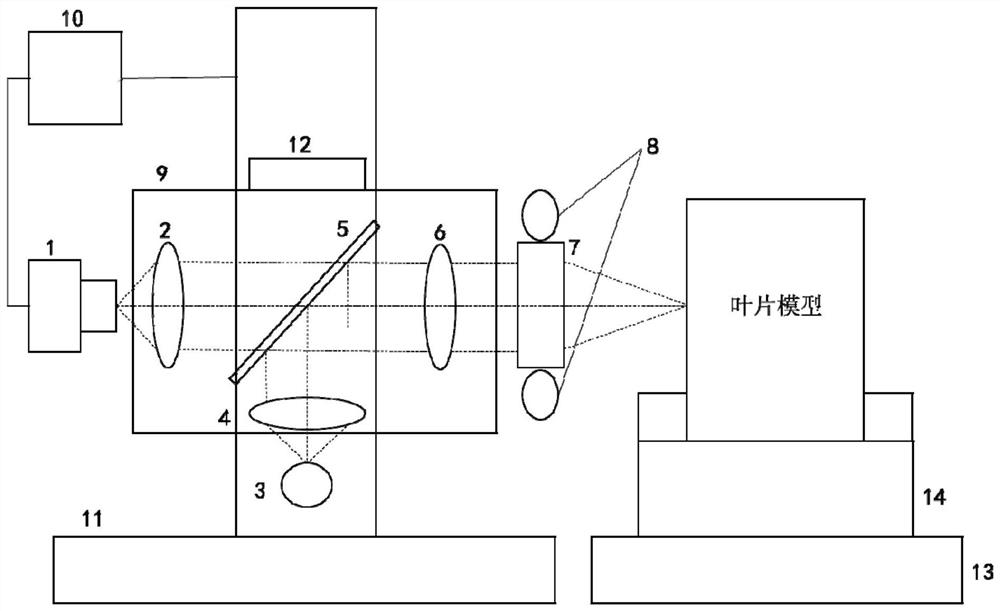

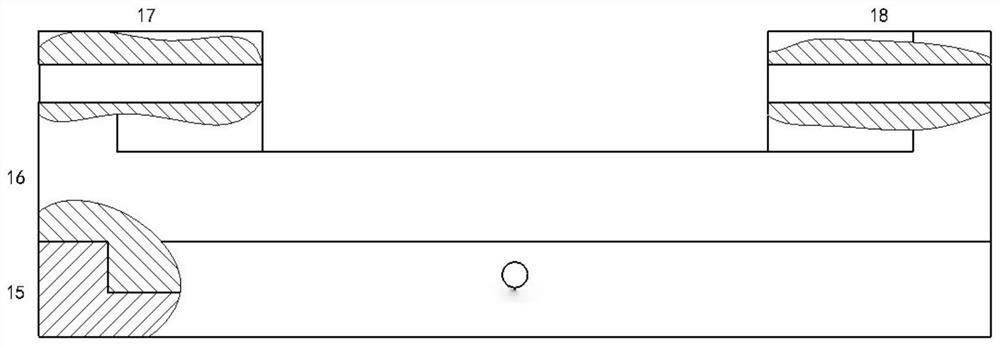

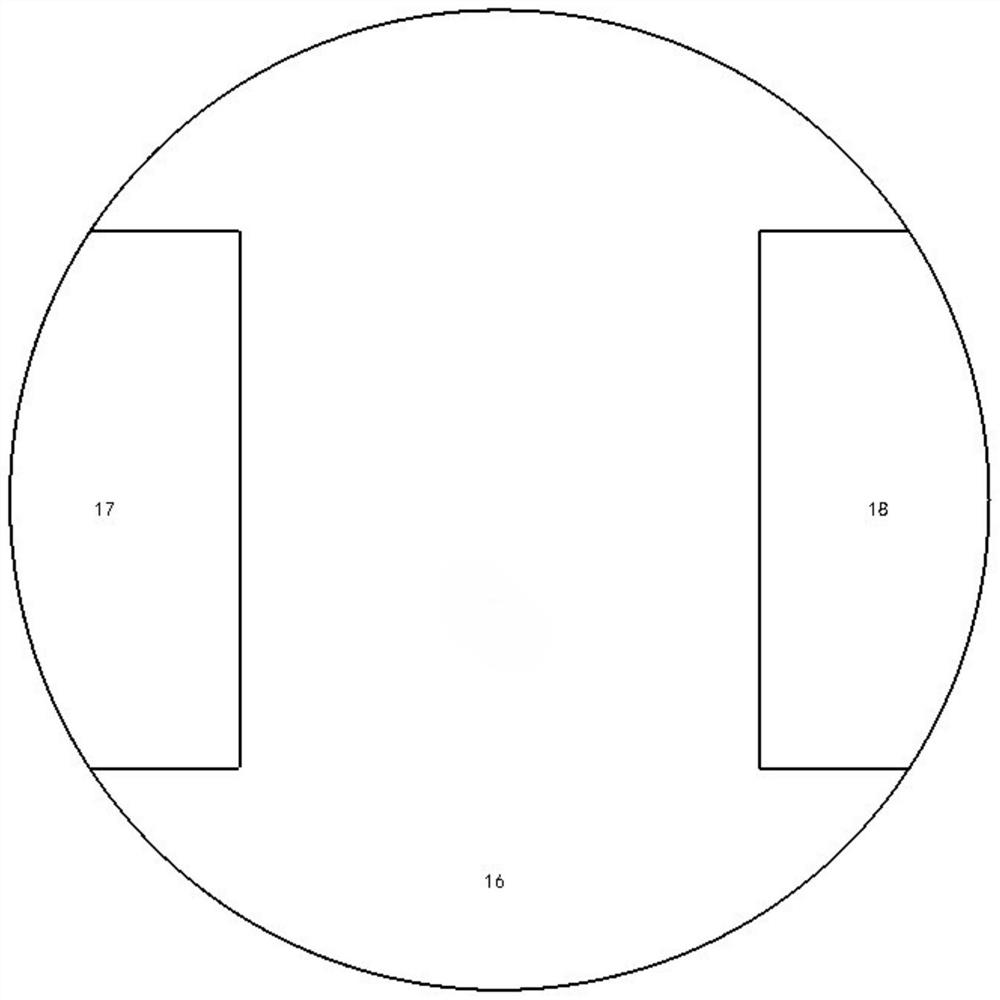

[0042] like figure 1 As shown in the figure, the three-dimensional detection system for the geometric parameters of the air film hole of the aero-engine blade based on the zoom microscope technology of the present invention includes a CCD camera 1, a first lens 2, a coaxial light source 3, a second lens 4, a beam splitting prism 5, and a third lens 6 , objective lens 7 , ring light source 8 , lens barrel 9 , computer 10 , XYZ three-dimensional electric translation stage 11 , right-angle connecting plate 12 , stage 13 and blade clamp 14 .

[0043] The CCD camera 1 is arranged on the leftmost side, and the first lens 2, the beam splitting prism 5, the third lens 6 and the objective lens 7 are arranged in sequence from left to right along the incident light path of the CCD camera 1. The stage 13 is arranged on the right side of the objective lens 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com