Mold for prefabricating cement piles

A technology of cement piles and molds, which is applied in the manufacture of tools, ceramic molding machines, etc., and can solve the problems of cement piles being damaged, pitted, and difficult to ensure that the outer surface of cement piles is flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

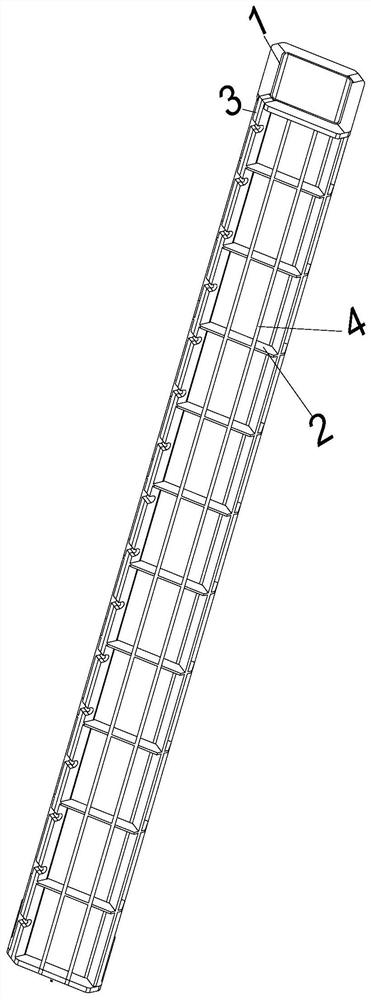

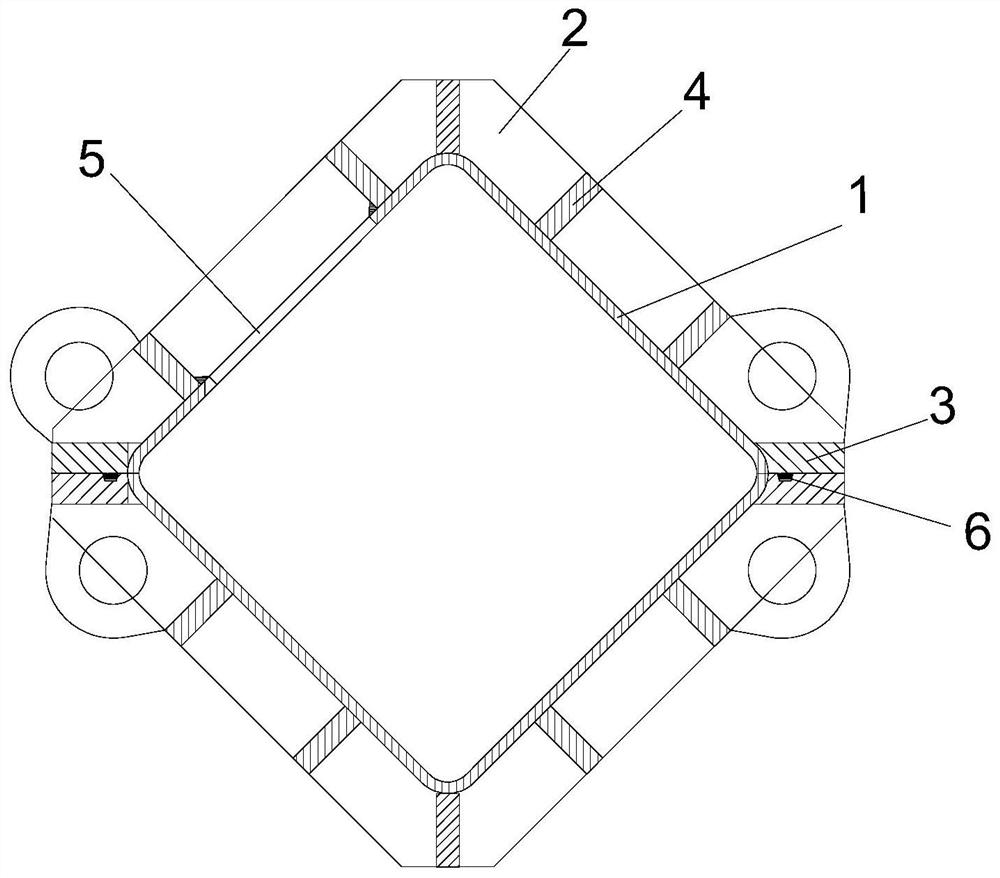

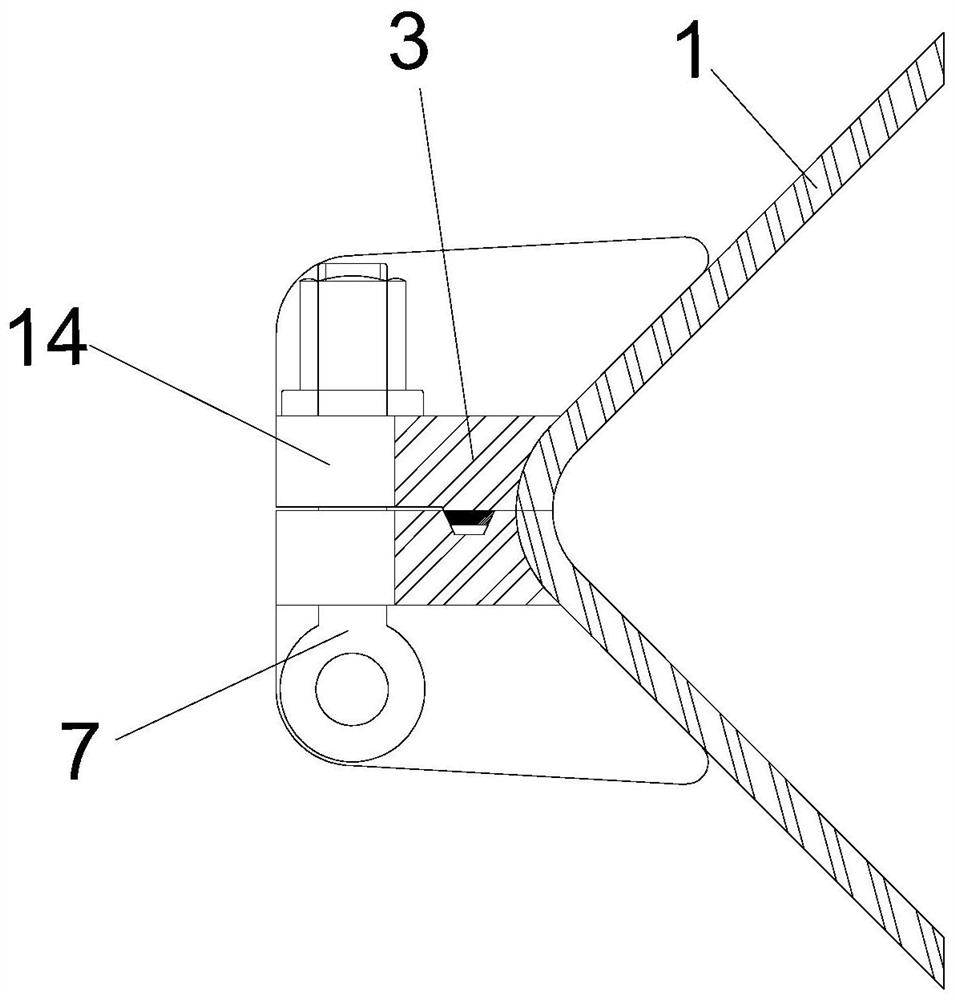

[0033] Please refer to Figure 1-Figure 4 as shown, figure 1 It is a schematic diagram of the three-dimensional structure of the present invention; figure 2 It is a schematic cross-sectional structure diagram of the present invention; image 3 It is a schematic diagram of the partial structure combination of the two mold bodies and the locking assembly of the present invention; Figure 4 It is a schematic diagram of the connection structure of two templates 1; Figure 5 It is a schematic cross-sectional structure diagram of two templates 1 combined.

[0034]The embodiment of the present application provides a mold for prefabricated cement piles, which includes a cuboid mold body. The mold body is divided into two mold bodies with any diagonal line of its cross section as the axis of symmetry. There is a feed port 5, and several locking components are arranged at the joint where the two mold bodies are joined together. The mold of the prefabricated cement pile set by this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com