Recycled concrete aggregate screening system

A technology for recycled concrete and aggregates, which is applied in the fields of filtration, solid separation, climate sustainability, etc., can solve the problems of poor sieving accuracy of sieving aggregates, achieve convenient aggregate removal, high sieving accuracy, and improve The effect of sieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

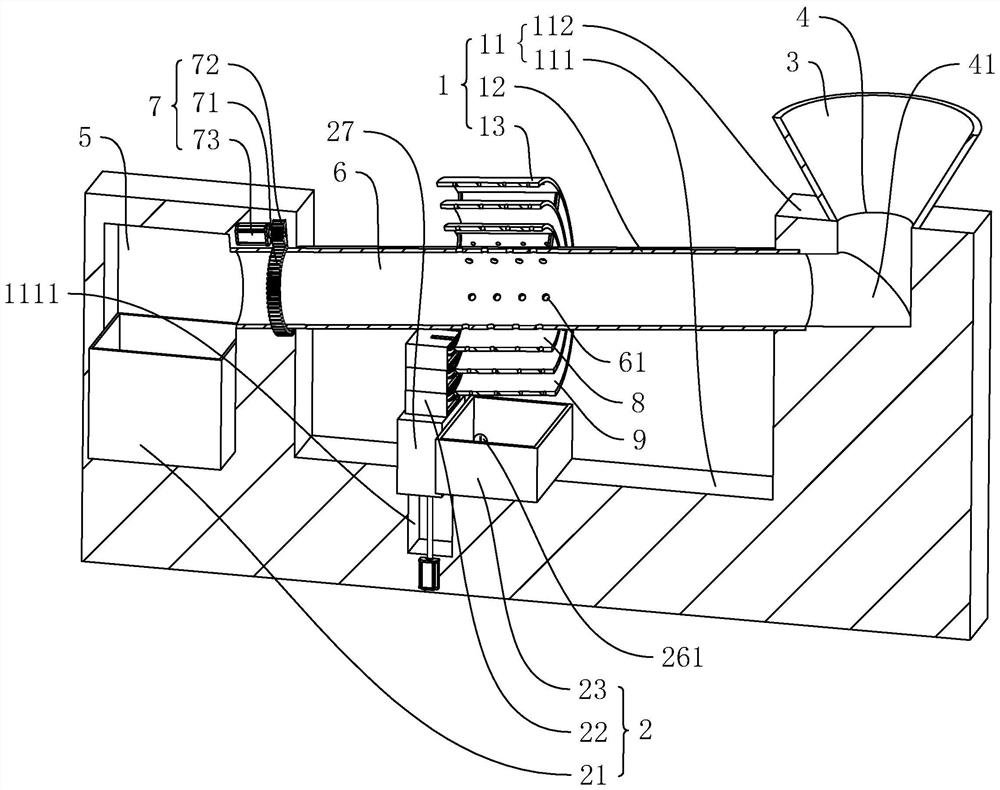

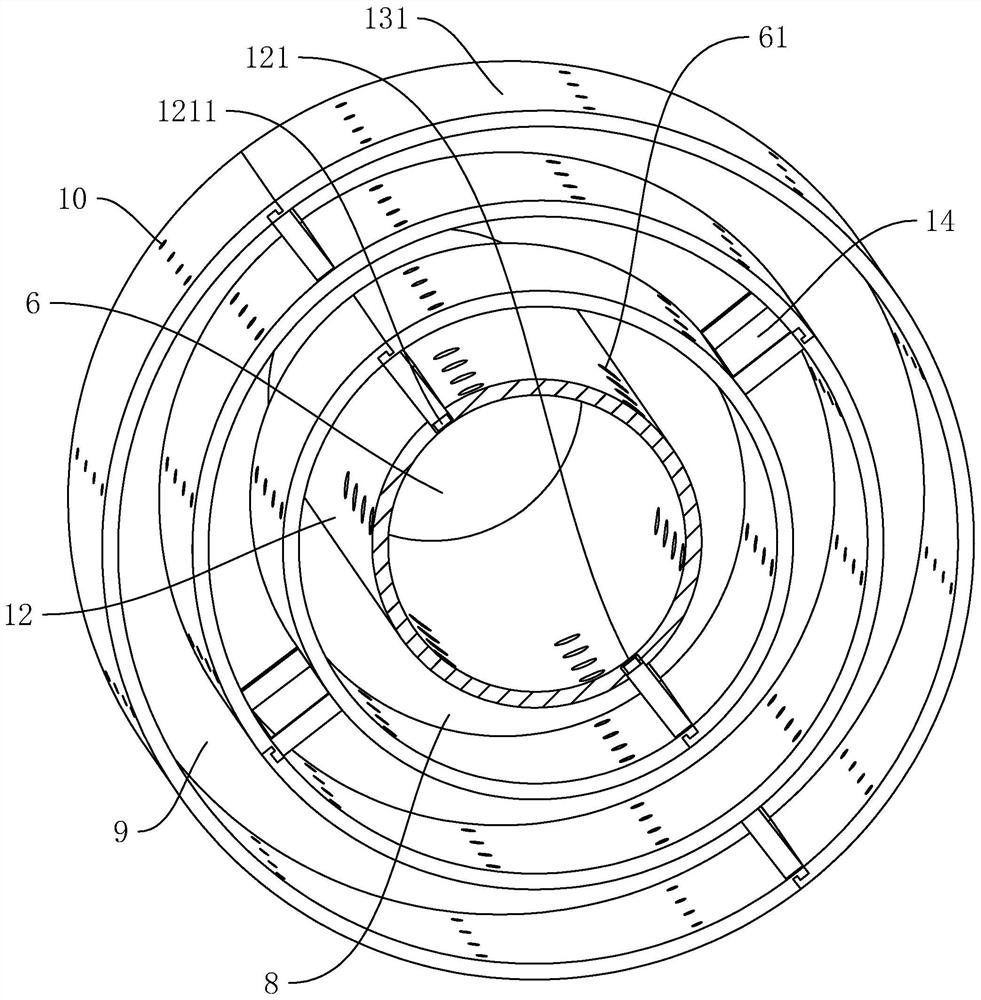

[0042] The following is attached Figure 1-7 The application is described in further detail.

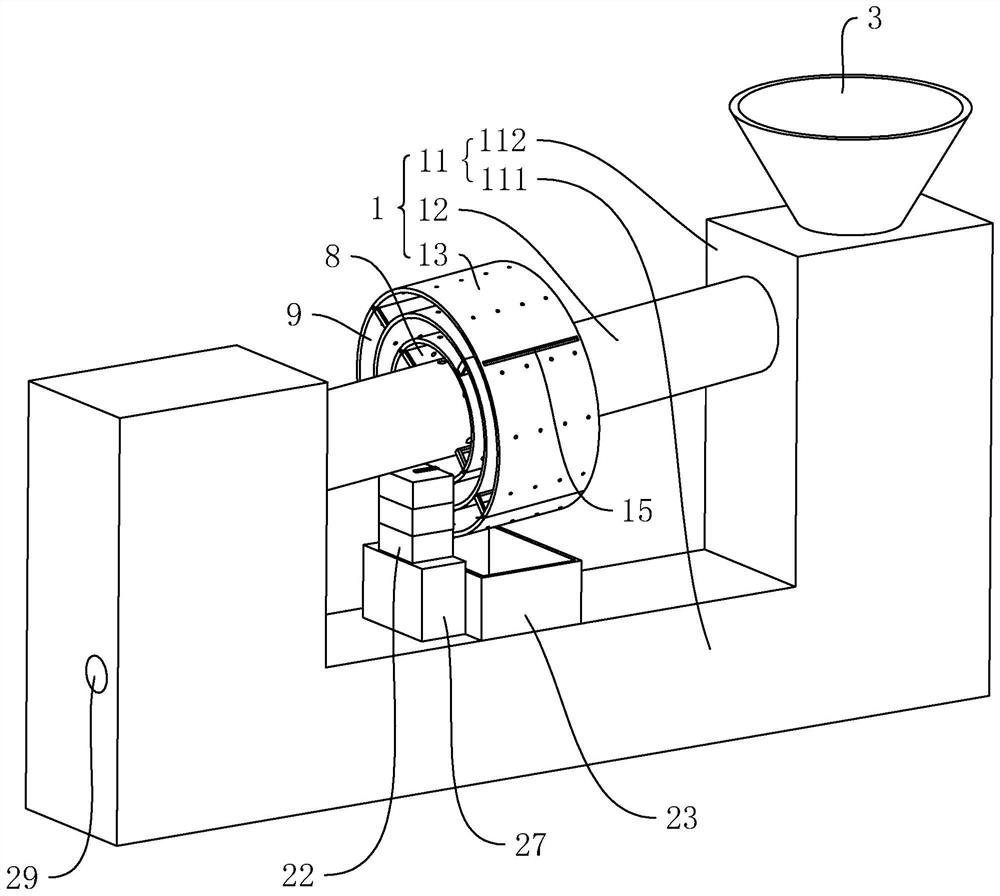

[0043] The embodiment of the present application discloses a recycled concrete aggregate screening system. see figure 1 and figure 2 , the recycling concrete aggregate screening system includes a screening device 1 and a collection device 2, the screening device 1 includes a frame 11, a drum 12 and a filter sleeve 13, the frame 11 includes a base 111 and two support columns 112, two Support column 112 is positioned at the top of base 111 and is arranged at intervals, and the lower end of two support columns 112 is fixedly connected with the upper end surface of base 111, and the upper end of one of them support column 112 is integrally fixed with hopper 3, and the upper end surface of above-mentioned support column 112 A feed port 4 is also provided, and the feed port 4 is located in the hopper 3 , and another supporting column 112 is provided with an accommodating cavity 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com