Cyanamide dimerization reactor and process thereof

A technology of cyanamide and reactor, which is applied in the field of cyanamide dimerization reactor and its process, can solve the problems of difficult automation, slow temperature adjustment and control, and low liquid heat exchange efficiency, and achieve a high degree of automation , Temperature adjustment and control is fast, and the effect of improving the flow field distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

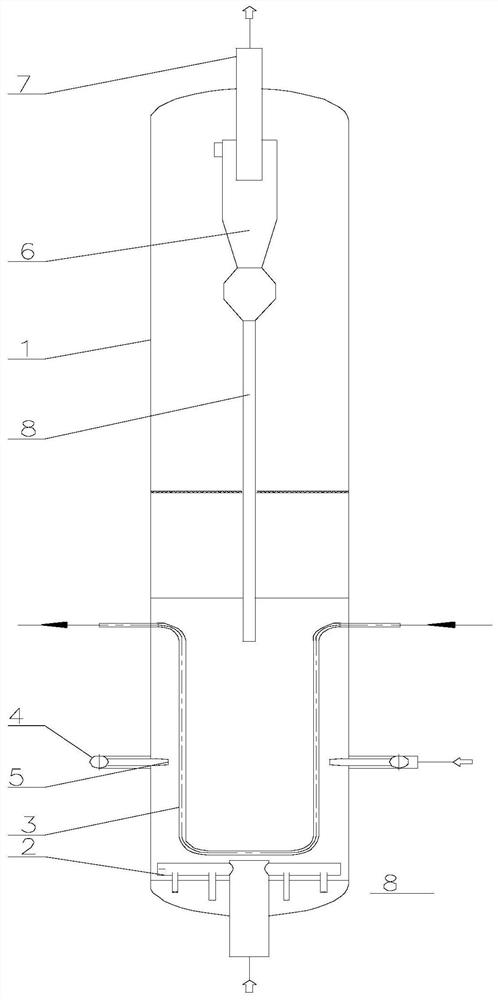

Image

Examples

Embodiment 1

[0038] A kind of cyanamide dimerization technique of above-mentioned device adopted in the present embodiment, comprises the following steps:

[0039] S1. Pass fluidization gas at 280°C into the reactor, control the pressure inside the reactor at 0.3MPa, and open the heat exchange device at the same time;

[0040] S2. Adjust the temperature of the heat exchange device according to the temperature and flow rate of the fluidized gas to control the temperature of the fluidized polymerization zone to be 130-200°C;

[0041] S3. After the temperature in the fluidized polymerization zone of the reactor is balanced and stable, cyanamide gas at 500-600°C is introduced;

[0042] S4. The cyanamide gas enters the fluidized polymerization zone, and undergoes a dimerization reaction under the action of a catalyst to generate a mixed gas containing dicyandiamide, and simultaneously uses a heat exchange device to cool down the fluidized polymerization zone;

[0043] S5. Separating the mixed ...

Embodiment 2

[0046] In this embodiment mode as a preferred embodiment of the present invention, a kind of cyanamide dimerization process comprises the following steps:

[0047] S1. Pass fluidization gas at 250°C into the reactor, control the pressure inside the reactor at 0.3MPa, and open the heat exchange device at the same time;

[0048] S2. Adjust the temperature of the heat exchange device according to the temperature and flow rate of the fluidized gas to control the temperature of the fluidized polymerization zone to be 130-200°C;

[0049] S3. After the temperature in the fluidized polymerization zone of the reactor is balanced and stable, cyanamide gas at 500-600°C is introduced;

[0050] S4. The cyanamide gas enters the fluidized polymerization zone, and undergoes a dimerization reaction under the action of a catalyst to generate a mixed gas containing dicyandiamide, and simultaneously uses a heat exchange device to cool down the fluidized polymerization zone;

[0051] S5. Separati...

Embodiment 3

[0054] In this embodiment mode as a preferred embodiment of the present invention, a kind of cyanamide dimerization process comprises the following steps:

[0055] S1. Pass fluidization gas at 250°C into the reactor, control the pressure inside the reactor at 0.6MPa, and open the heat exchange device at the same time;

[0056] S2. Adjust the temperature of the heat exchange device according to the temperature and flow rate of the fluidized gas to control the temperature of the fluidized polymerization zone to be 130-200°C;

[0057] S3. After the temperature in the fluidized polymerization zone of the reactor is balanced and stable, cyanamide gas at 500-600°C is introduced;

[0058] S4. The cyanamide gas enters the fluidized polymerization zone, and undergoes a dimerization reaction under the action of a catalyst to generate a mixed gas containing dicyandiamide, and simultaneously uses a heat exchange device to cool down the fluidized polymerization zone;

[0059] S5. Separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com