Permanent magnet bonding device

A permanent magnet and bonding technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of permanent magnets such as easy misalignment, fragility, and low surface magnetism, and reduce the risk of collapse. The effect of high bonding precision and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

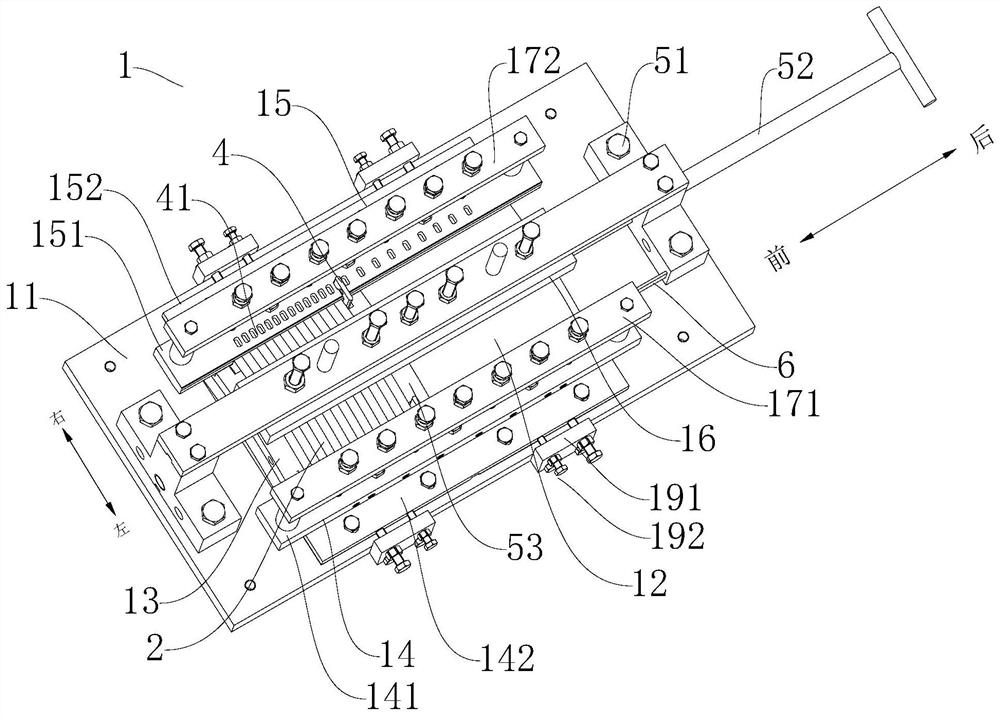

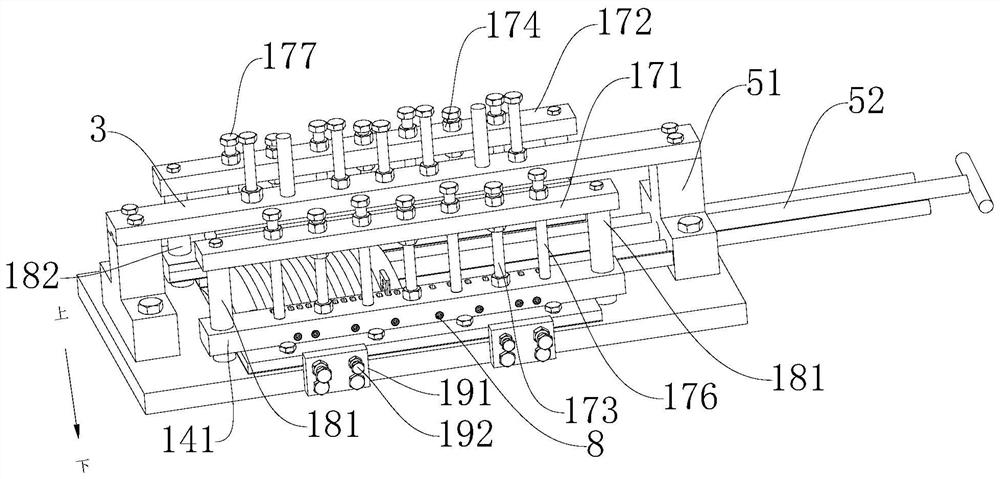

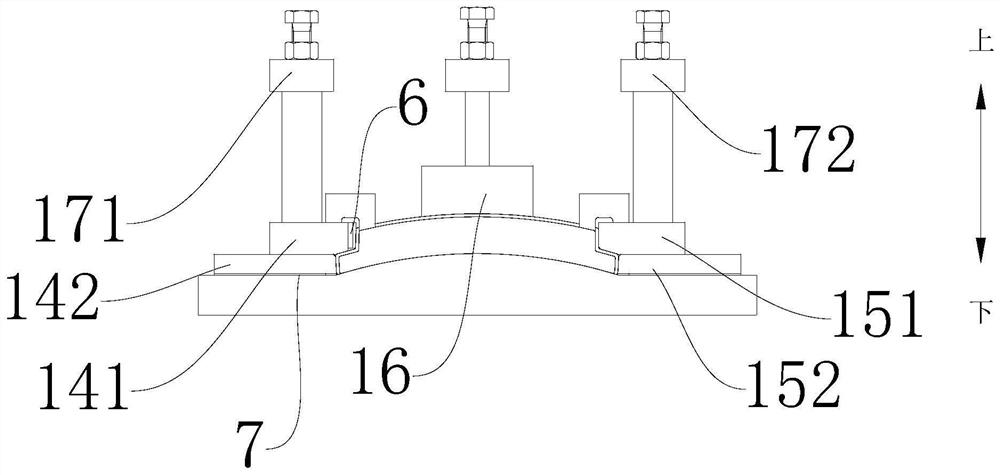

[0028] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0029] The following is based on Figure 1-3 A bonding apparatus 1 for bonding a permanent magnet 2 according to an embodiment of the present invention will be described. It should be noted that the permanent magnet 2 here refers to a small piece of permanent magnet or a permanent magnet piece, and the bonding device 1 provided in the embodiment of the present invention is used to bond several permanent magnets 2 to form a finished permanent magnet that can be used .

[0030] Such as figure 1 As shown, the bonding device 1 includes a base 11 and a sliding track assembly. The sliding track assembly is arranged on the upper surface of the base 11, the sliding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com