A Construction Technology of Triple Arch in Crossing Section of Large-Section Tunnel

A construction technology and large-section technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as low safety factors and achieve the effect of reducing hidden dangers of subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

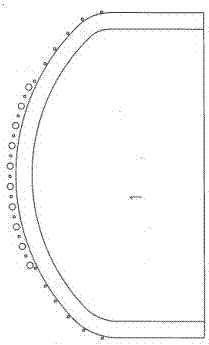

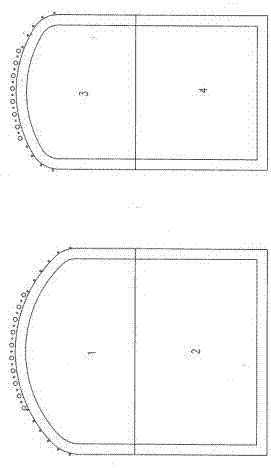

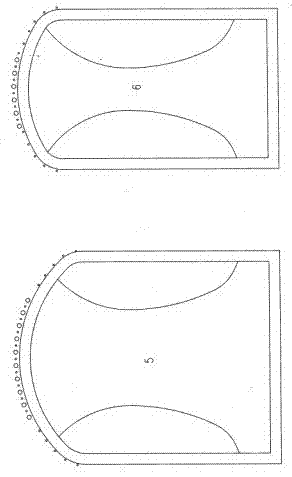

[0019] A construction technique for triple arches in crossing sections of large-section tunnels, comprising the following steps:

[0020] The first step is to draw the excavation contour line of the upper left middle pilot tunnel on the tunnel excavation work surface, and perform advanced support for the upper left middle pilot tunnel above the excavation contour line of the upper left middle pilot tunnel, including the large pipe shed and the advanced Small conduit, and pre-grouting to reinforce the arch soil, then excavate the soil of the upper left middle pilot tunnel (1) and apply initial support; on the tunnel excavation work surface, draw the upper right middle pilot tunnel for excavation Contour line, above the contour line of the excavation of the upper right middle pilot tunnel, perform advanced support for the upper right middle pilot tunnel, including the large pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com