Material checking method and device, computer equipment and storage medium

A technology of computer equipment and computer programs, which is applied in the field of inspection, can solve problems such as inability to timely and efficiently check materials, and inability to obtain material information in a timely and accurate manner, so as to shorten the checking time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

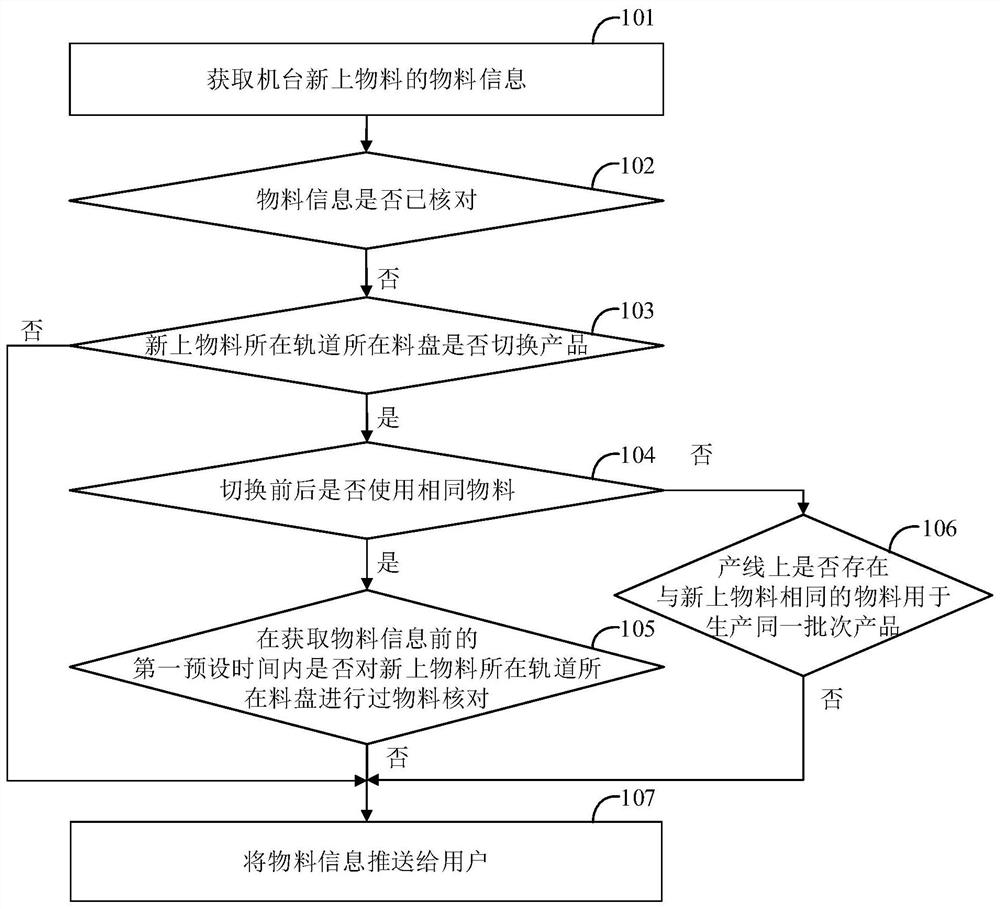

[0073] figure 1 It is a flow chart of the material checking method provided by Embodiment 1 of the present invention. The material checking method is applied to computer equipment. The material checking method pushes the material information to be checked to the user in time for checking.

[0074] Such as figure 1 As shown, the material checking method includes:

[0075] 101. Obtain the material information of the new material on the machine.

[0076] In one embodiment, the material information includes the line number, machine number, track number, tray number, material number, loading time, machine area, etc. of the newly loaded material.

[0077] The line number of the newly uploaded material indicates the production line where the newly uploaded material is located.

[0078] The machine number of the newly loaded material indicates the machine where the newly loaded material is located. In one embodiment, the machine is an SMT (Surface Mounted Technology, surface mou...

Embodiment 2

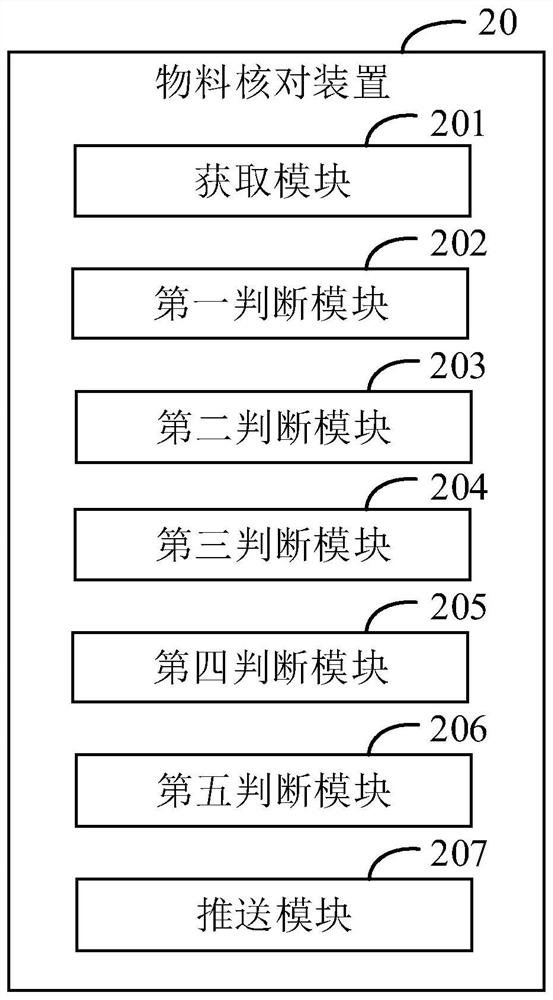

[0133] figure 2 It is a structural diagram of the material checking device provided by Embodiment 2 of the present invention. The material checking device 20 is applied to computer equipment. The material checking device 20 pushes the material information to be checked to the user in time for checking.

[0134] Such as figure 2 As shown, the material checking device 20 may include an acquisition module 201 , a first judgment module 202 , a second judgment module 203 , a third judgment module 204 , a fourth judgment module 205 , a fifth judgment module 206 and a push module 207 .

[0135] The obtaining module 201 is used to obtain material information of new materials on the machine.

[0136] In one embodiment, the material information includes the line number, machine number, track number, tray number, material number, loading time, machine area, etc. of the newly loaded material.

[0137] The line number of the newly uploaded material indicates the production line where...

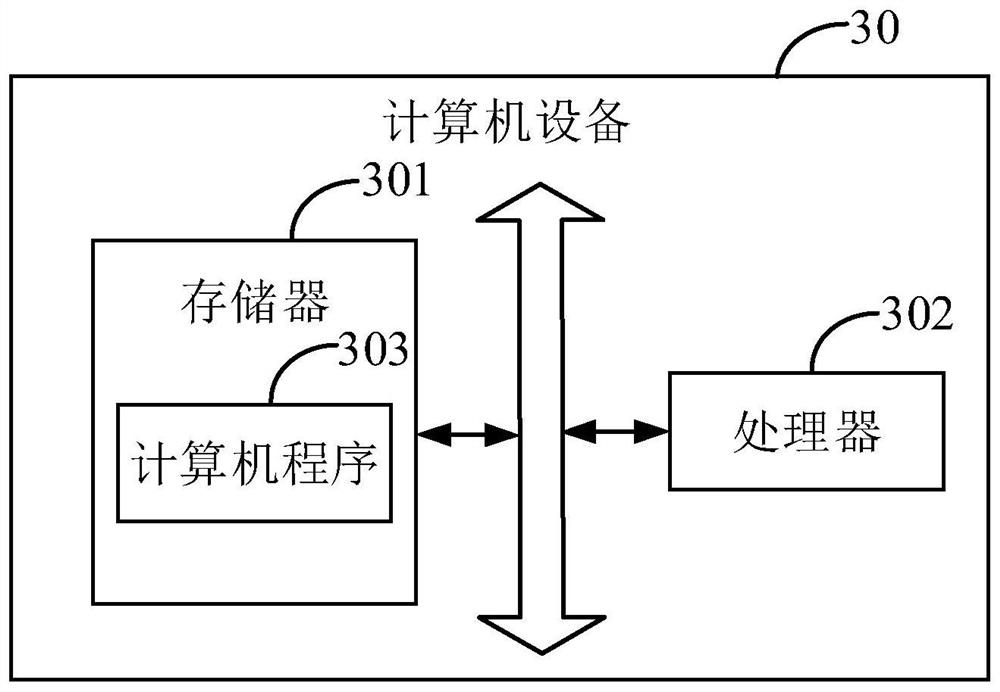

Embodiment 3

[0189] This embodiment provides a storage medium, on which a computer program is stored, and when the computer program is executed by a processor, the steps in the above embodiment of the material checking method are implemented, for example figure 1 101-107 shown:

[0190] 101. Obtain the material information of the new material on the machine;

[0191] 102. Determine whether the material information has been checked;

[0192] 103. If the material information has not been checked, judge whether the tray where the track where the newly loaded material is located is to switch products;

[0193] 104. If the product is switched on the tray where the track where the newly loaded material is located, it is judged whether the same material is used before and after the switch;

[0194] 105. If the same material is used before and after switching, it is judged whether a material check has been performed on the tray where the track of the newly loaded material is located within the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com