Gas-solid separation fluidized bed spatial characteristic research device and characteristic research method

A technology of spatial characteristics and gas distribution device, which is applied in measurement devices, aerodynamic tests, instruments, etc., can solve the problems of quantitative analysis of gas-solid fluidization spatial characteristics, weak research and other problems, and achieves low maintenance costs and operation. Simple, convenient, impactful and credible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The method includes the following steps:

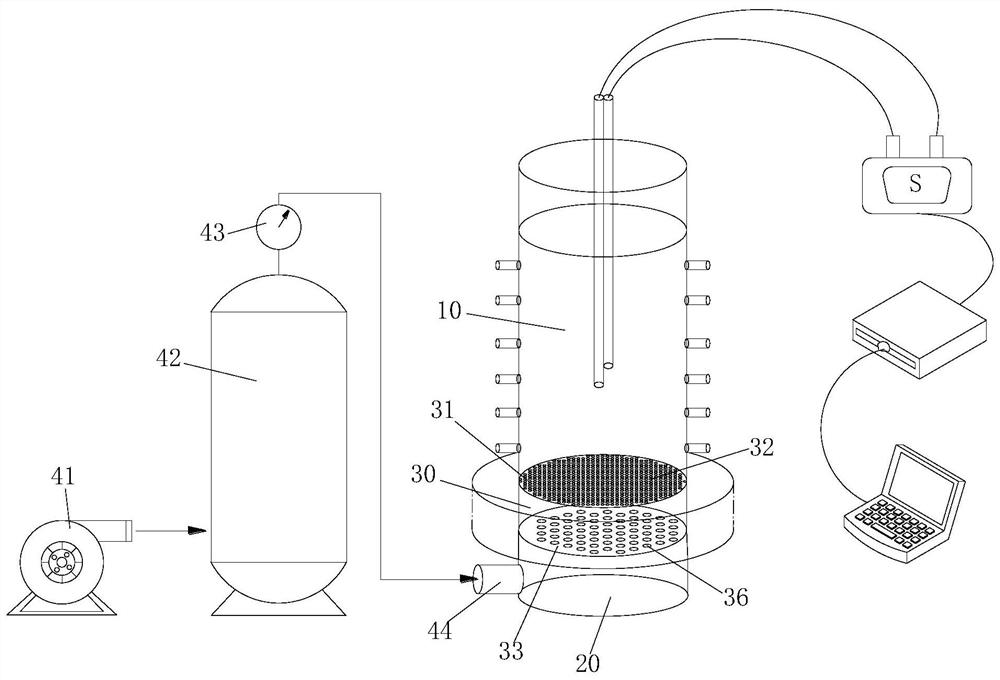

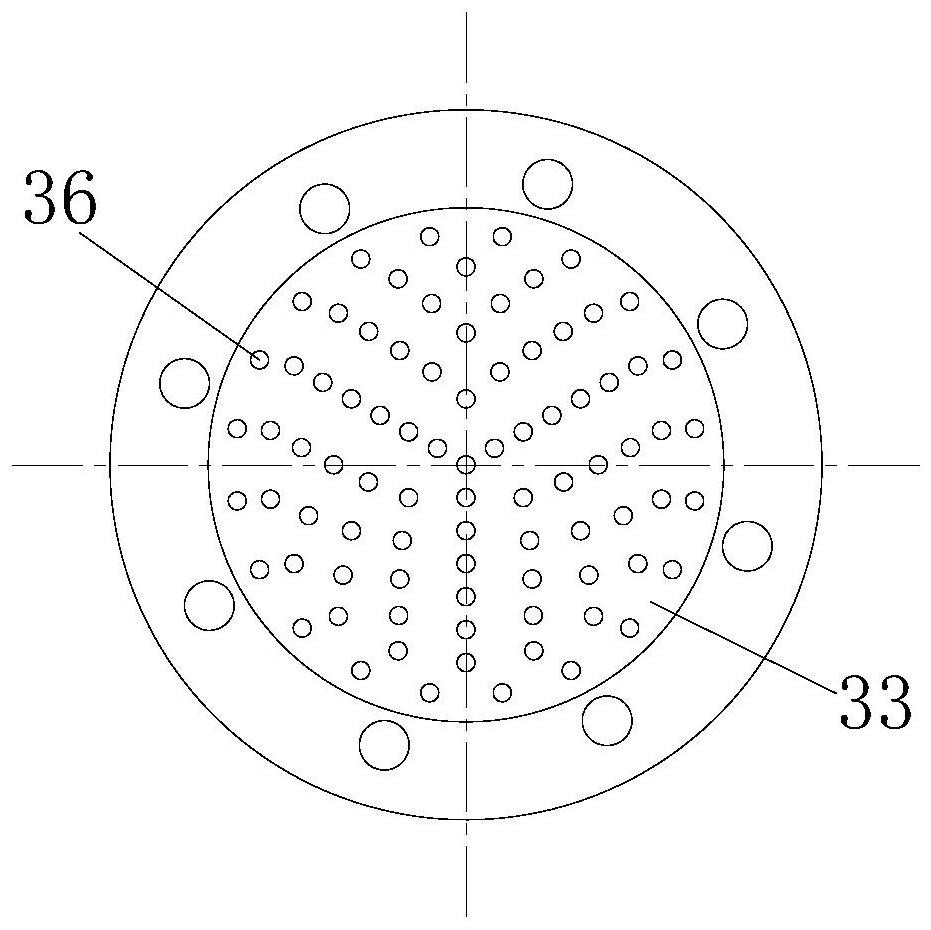

[0057] Step 1. Put magnetite powder of 0.15-0.175mm into the fluidized bed, set the height of the static bed to 150mm-250mm, adopt a uniform opening air distribution plate with an overall opening rate of 10%, and turn on the Roots blower 41 , the compressed air enters the air distribution chamber 20 sequentially through the air bag 42, the rotameter 43, and the intake pipe 44, and the compressed air enters the fluidized bed body 10 through the gas distribution device 30 in the air distribution chamber. The pre-air distribution plate used in the test for A1.

[0058] Step 2. In order to characterize the spatial distribution characteristics of solid particles in different positions of the gas-solid separation fluidized bed as much as possible, design representative sampling points to study the distribution characteristics of the mass flow rate of solid particles through three-dimensional sampling of the bed. points such as Fig...

Embodiment 2

[0063] combine figure 1 , to further study the influence mechanism of different factors on the spatial characteristics of the gas-solid separation fluidized bed. In this embodiment, the research on the spatial characteristics of the gas-solid separation fluidized bed using the above-mentioned device includes the following steps:

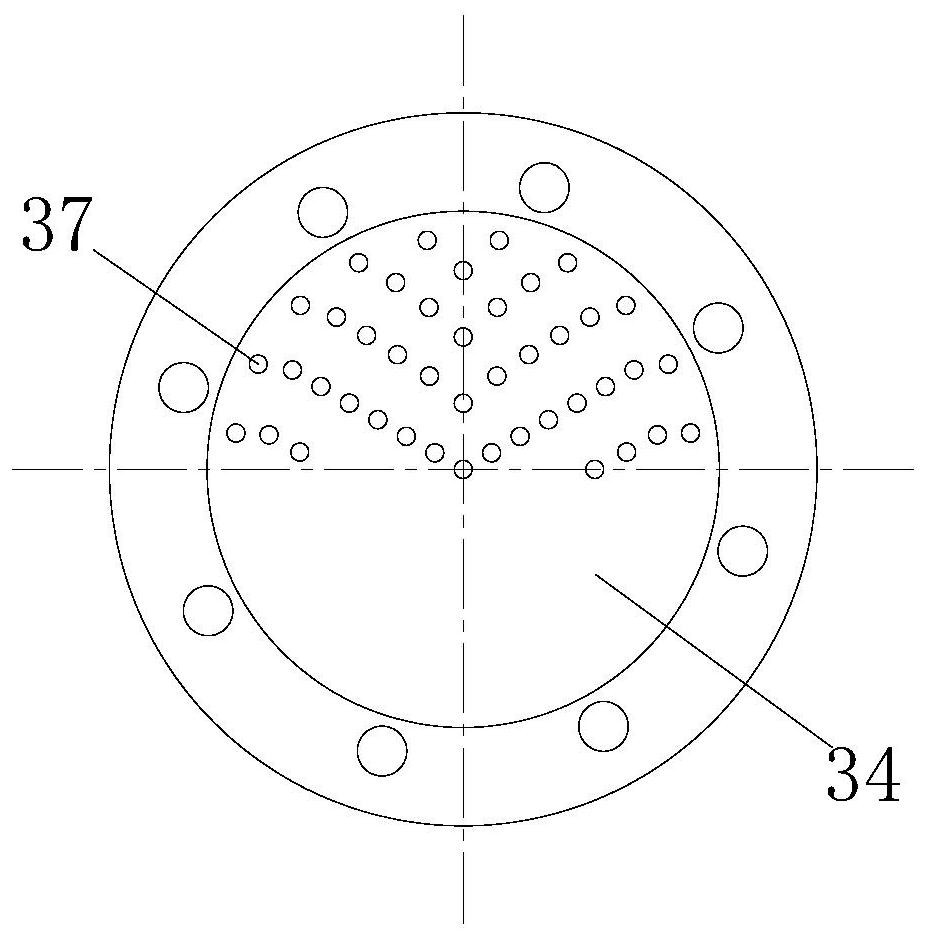

[0064] Step 1. Put 0.15-0.175mm magnetite powder into the fluidized bed, set the height of the static bed to 200mm, adopt a uniform opening air distribution plate with an overall opening rate of 20%, turn on the Roots blower 41, and compress The air enters the air distribution chamber 20 sequentially through the air bag 42, the rotameter 43, and the air inlet pipe 44. The compressed air first passes through a pre-distribution air distribution chamber, and then enters the fluidized bed body 10 through the gas distribution device 30 in sequence. Three kinds of gas distribution devices are designed according to the experimental requirements. The hole ty...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap