Truss plate pouring concrete pull-up soft support construction device and construction method thereof

A technology of construction device and truss plate, which is used in construction, building structure, formwork/formwork/work frame, etc., can solve the problems of difficult to guarantee safety, high cost of super-high formwork, slow construction period, etc. The effect of saving manpower and financial resources, simple structure, safe and reliable construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

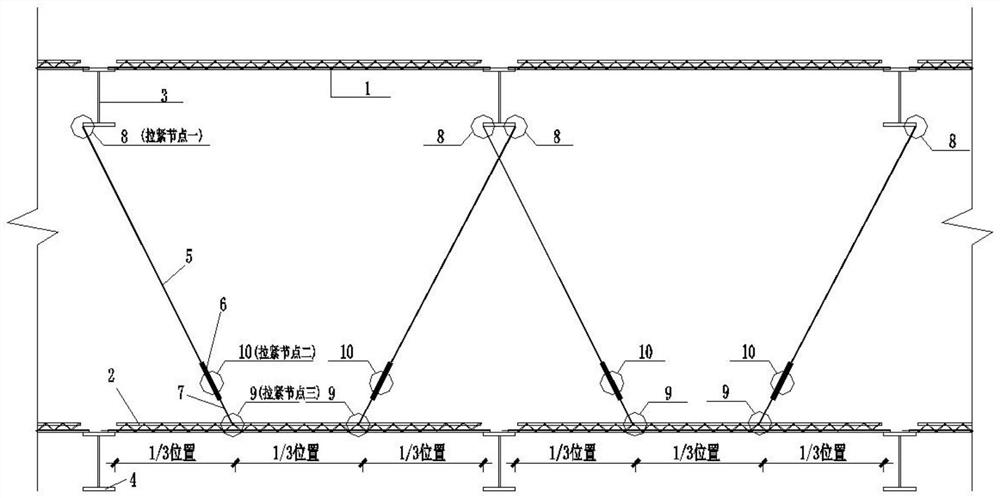

[0023] Embodiment 1: as Figure 1-2 As shown, this embodiment provides a truss slab pouring concrete upper pull soft support construction device, including the upper truss slab 1 and the lower truss slab 2 corresponding to each other after laying, and the lower part of the upper truss slab 1 is connected with a number of structural beams. 3. The lower part of the lower truss plate 2 is connected with a number of structural beams 2 4, and the structural beam 1 3 is connected with a steel wire rope 5 through a clamp, and the lower part of the steel wire rope 5 is connected to the pull hook 7 on the lower truss plate 2 through the turnbuckle bolt 6 Connection, the hook is made of Q235B material, 20 mm in diameter round steel, the steel wire rope is used as the main component of the force; the clamp is used as the upper node to connect the structural beam and the steel wire rope; the screw hook is used as the lower node to connect the truss plate. The wire rope is used for fixing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com