Asphalt concrete preparation process

A kind of asphalt concrete and preparation technology, which is applied in the field of asphalt concrete, can solve the problems of stone waste, asphalt is difficult to remove, and finished materials are easy to be mixed with large crushed stones, so as to achieve the effect of preventing waste and uniform distribution of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

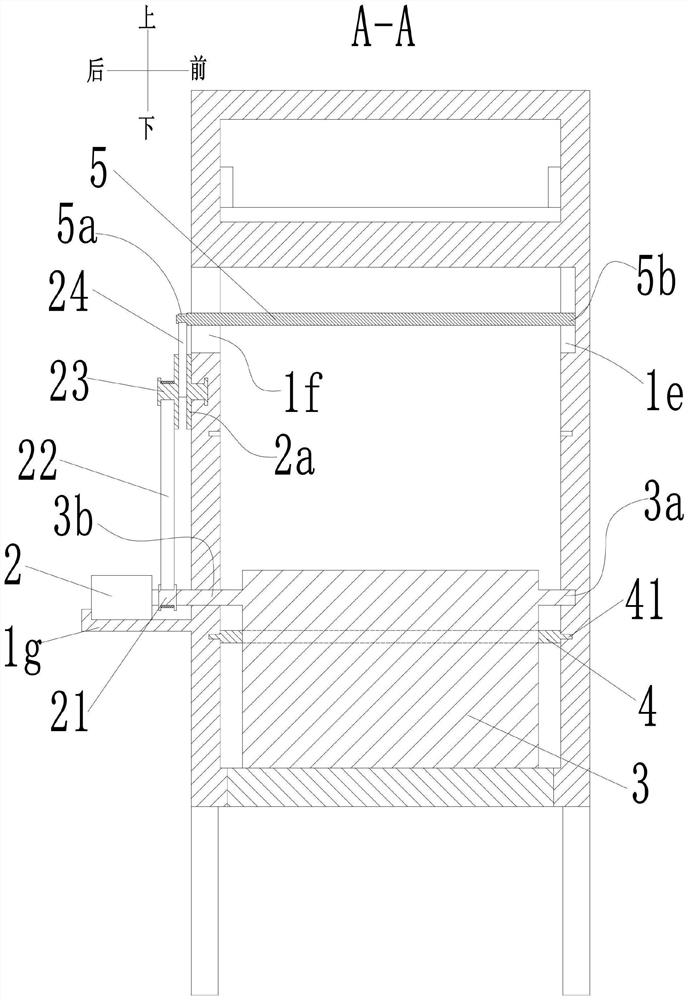

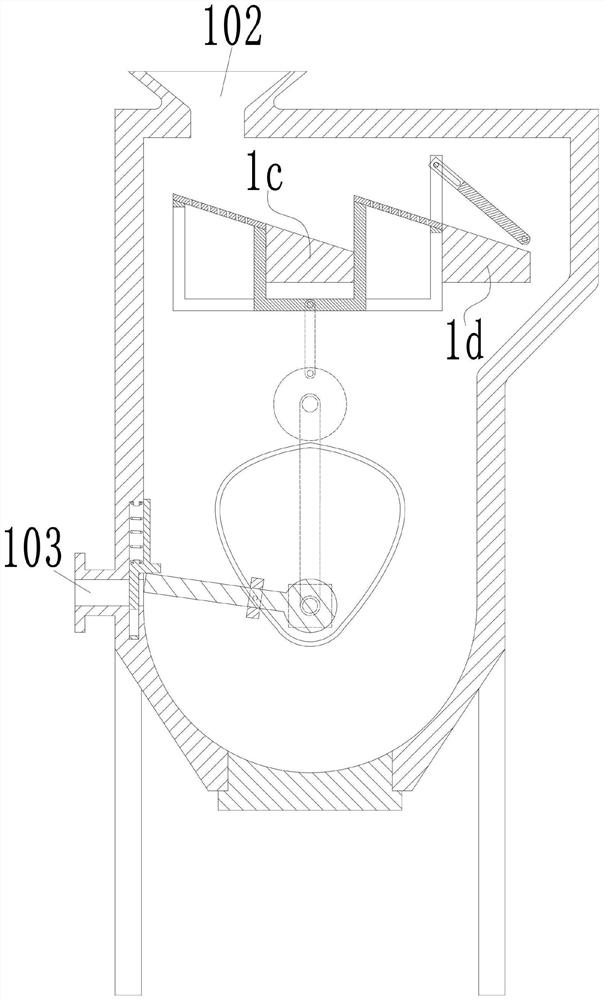

[0032] see Figure 1-6 Shown, a kind of asphalt concrete preparation process, described asphalt concrete preparation process uses the mixing box 1 that is arranged along the vertical direction, the lower end of described mixing box 1 is a mixing chamber, and the bottom of described mixing box 1 is provided with mixing chamber 101 is connected to the discharge port 104, the discharge port 104 is provided with a material cover 11, the upper end of the mixing tank 1 is provided with a stone inlet 102, and the mixing tank 1 is provided with an asphalt inlet 103 on the side wall near the lower end; The lower end of the stone inlet 102 in the mixing box 1 is provided with a stone screening and crushing assembly, the mixing box 1 is provided with a stirring assembly in the mixing chamber 101, and the side wall of the mixing box 1 is provided with a switch that cooperates with the mixing assembly. assembly, the switch assembly is used to control the opening and closing of the asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com