Process for synchronously preparing low-nitrogen-content bio-oil and hydrothermal carbon from sludge

A nitrogen content and bio-oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oils. It can solve the problems of unsatisfactory water content, high pollution risk, and high energy consumption, and improve the quality of bio-oil. , mild reaction conditions and good fuel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: application example

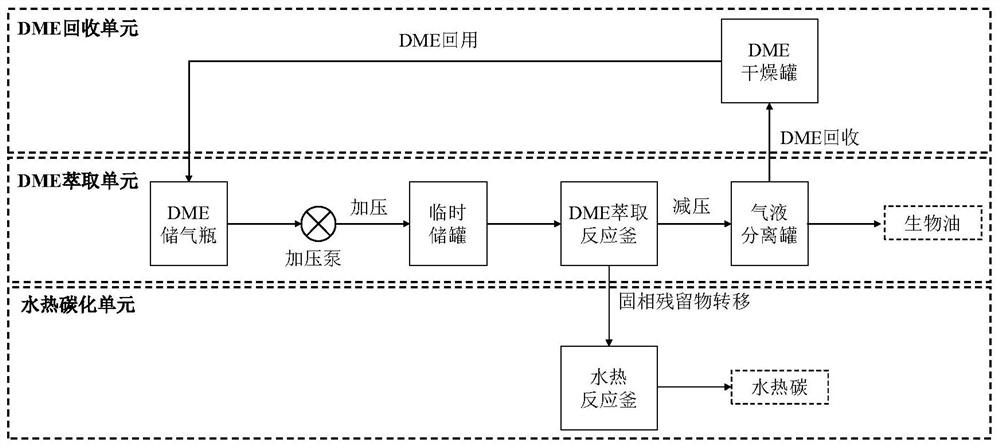

[0036] The process for synchronous preparation of bio-oil with low nitrogen content in sludge and hydrothermal carbon, specifically includes the following steps:

[0037] Step 1: Pressurize and liquefy the DME in the DME gas cylinder through the booster pump and store it in the L-DME temporary storage tank for later use. After the booster pump is boosted, the pressure is 0.5-3MPa; Mud (moisture content 85%) was put into the DME extraction reactor, and then passed into L-DME to control the mass ratio of L-DME to the water content in the sludge, reaction time, reaction temperature, stirring speed distribution 15, 20min, 25 ℃, 750r / min.

[0038] Step 2: After the reaction is completed, open the valve below the DME extraction reactor and use the pressure difference (0.5Mpa) between the DME extraction reactor and the gas-liquid separation tank to pass through the filter screen (180 mesh stainless steel filter screen) laid at the bottom of...

Embodiment 2

[0041] Get 50g of sewage plant municipal dewatering sludge (moisture content 85%), measure the ash content and carbon content of former sludge, put this sludge into DME extraction reactor afterwards, obtain biological oil and water according to the process method of embodiment 1 Hot carbon, the properties of the measured product are shown in Table 1.

[0042] Table 1 Comparison of raw sludge and product properties

[0043]

[0044] a Based on dry basis weight

[0045] b Based on ash-free dry basis weight

[0046] It can be seen from Table 1 that L-DME extraction can greatly reduce the nitrogen content and improve the quality of bio-oil; at the same time, after the reaction, the C content increases by about 1.3 times, and the obtained hydrothermal carbon specific surface area can reach 15.782m2 / g, Subsequent modification can be further improved, so that it can be used as an adsorption material.

Embodiment 3

[0048] Get 50g of sewage plant municipal dewatered sludge (moisture content 85%) and put it into the reactor, then pass into liquid dimethyl ether, control the mass ratio of liquid dimethyl ether and water content in the sludge, reaction time, reaction temperature, stir The speed distribution is 15, 20min, 25°C, 750r / min. After the reaction is completed, the moisture content of the sludge is measured by the drying method.

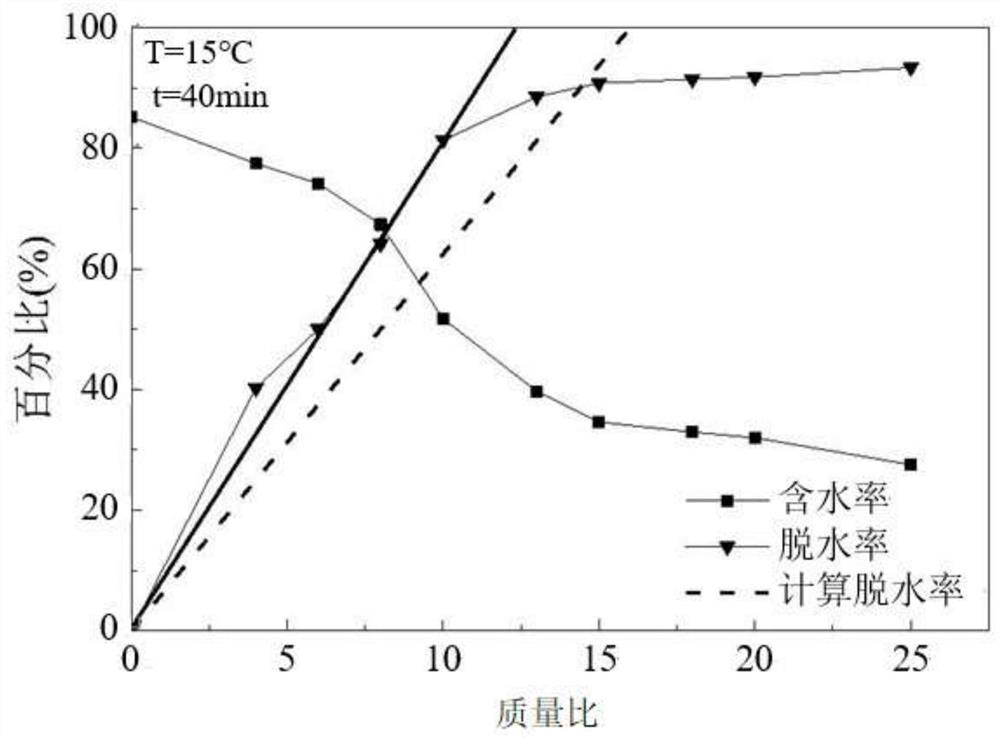

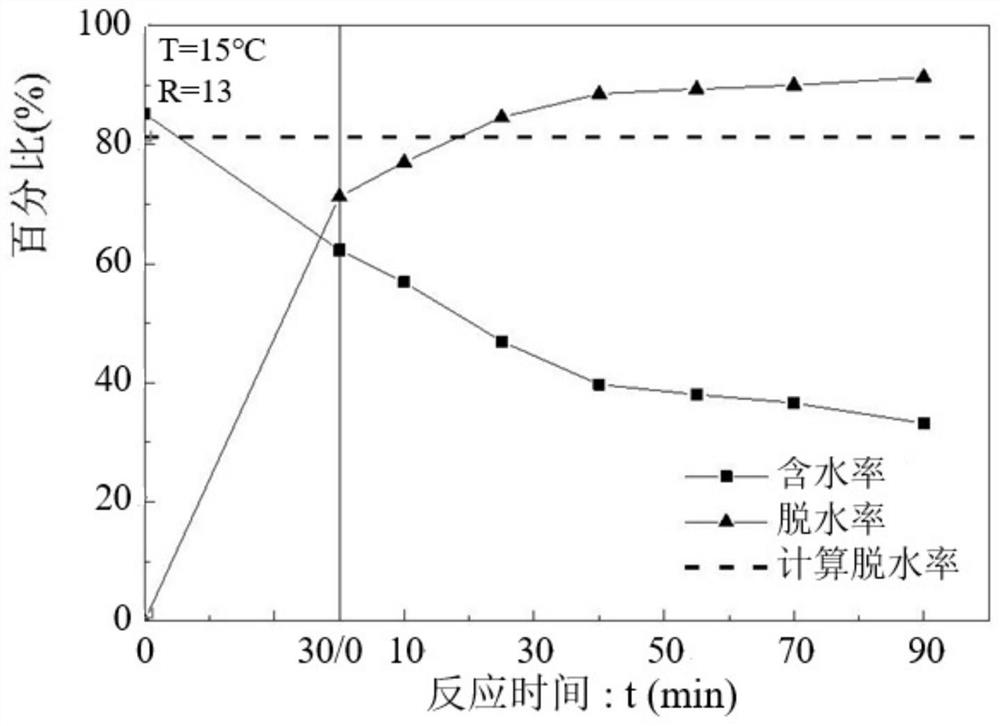

[0049] Depend on figure 2 , 3 , 4. It can be seen that the effect is better when the mass ratio of liquid dimethyl ether to sludge water content is 10 to 13 times, the reaction time is 30 to 40 minutes, and the reaction temperature is 20 to 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com