Intelligent assembling system and method for swing frame assembly of intelligent gas meter based on Internet of Things

An assembly system, Internet of Things technology, applied in conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of insufficient assembly of rotating frame components, time-consuming and laborious, affecting product quality, etc., to improve assembly efficiency and assembly. Quality, increased contact area, precise clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

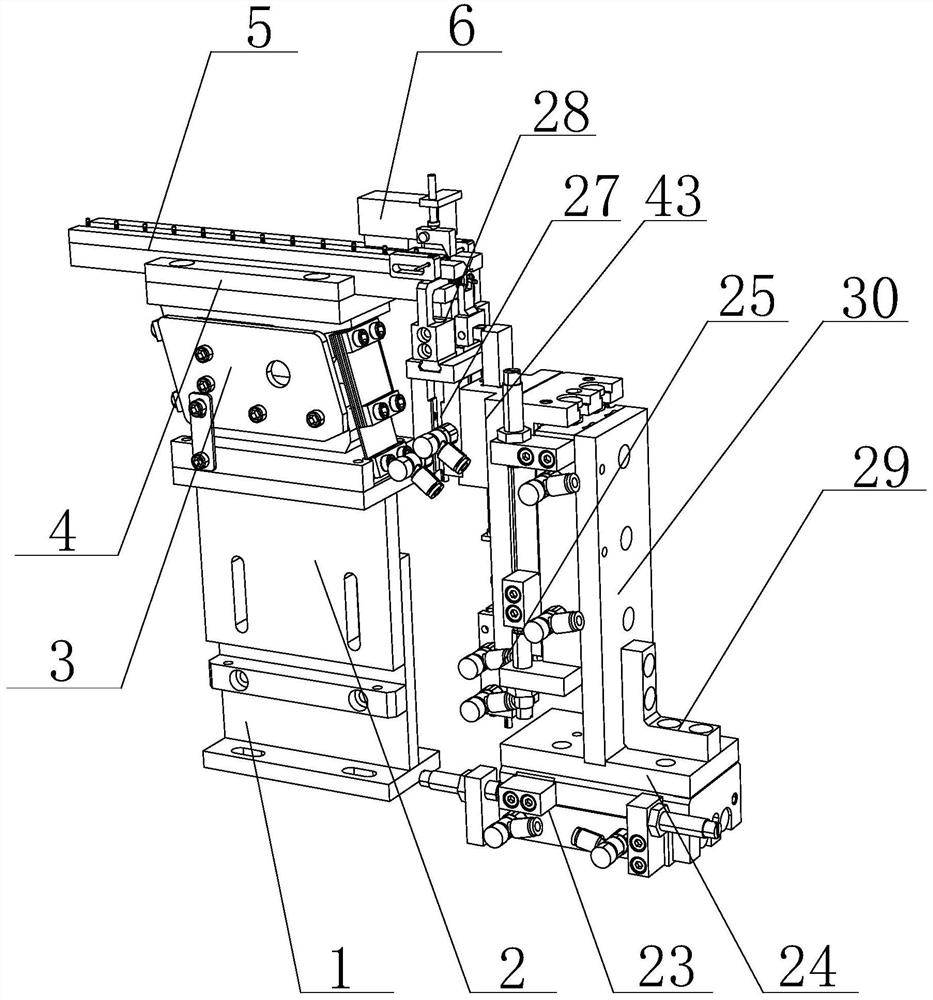

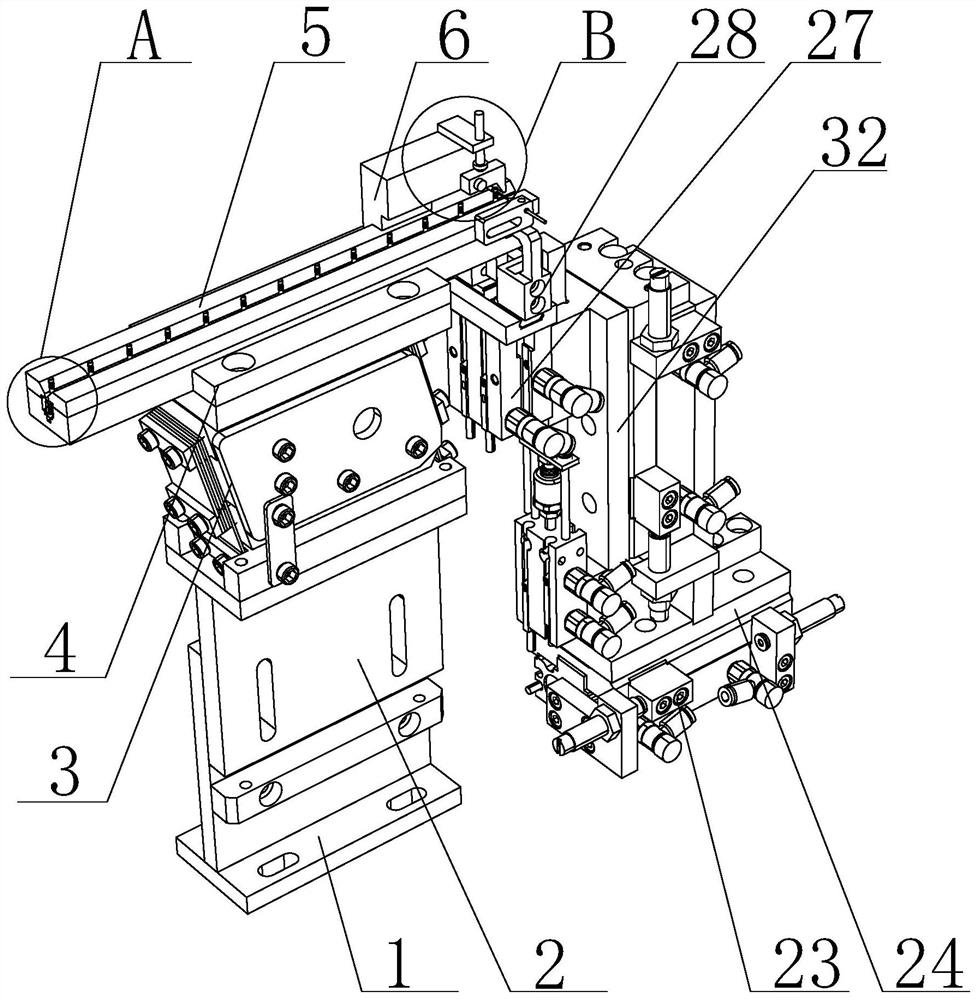

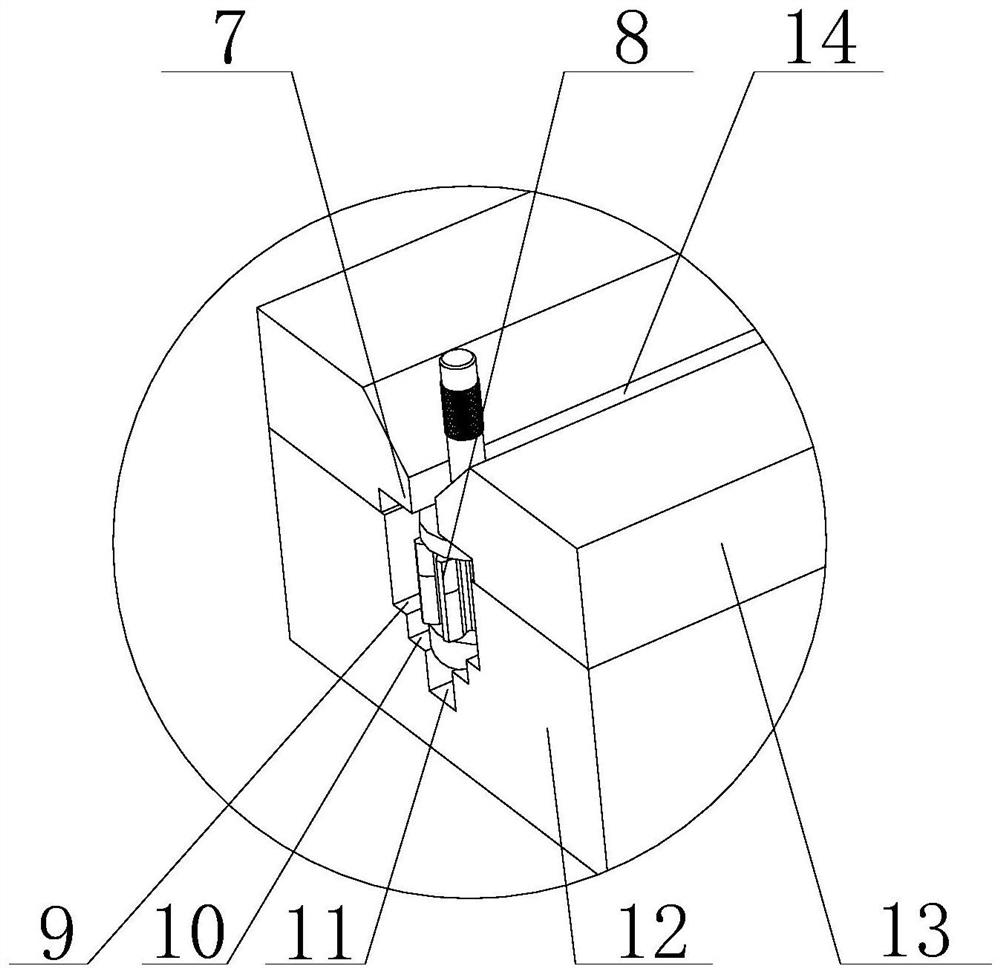

[0062] like Figure 1 to Figure 8 As shown, the present invention includes a management platform, a feeding mechanism and an assembly mechanism, the feeding mechanism includes a track 5, and the track 5 can limit the orientation of the rotating shaft 20 on the swing frame assembly 8, and transport the swing frame assemblies to the assembly mechanism one by one ; The assembly mechanism includes a grabbing assembly and a mounting assembly, the grabbing assembly is used to grab the gear 21 of the rotary frame assembly 8 on the output end of the feeding mechanism, and the mounting assembly is used to grab the rotary frame assembly 8 The frame assembly 8 is transferred to the assembly line, and the rotating shaft of the swivel frame assembly 8 can be pushed into the assembly hole.

[0063] The management platform set in this technical solution is a controller, which is connected with the feeding mechanism and the assembly mechanism. The set feeding mechanism can be used to automati...

Embodiment 2

[0098] The intelligent assembly method of the intelligent gas meter swivel frame assembly of the Internet of Things includes the following steps:

[0099] 1) The swing frame assembly 8 enters the track 5 through the vibrating plate, and uses the track 5 to move the swing frame assembly one by one toward the output port;

[0100] 2) When the inner swing frame assembly on the track 5 moves to the swing block 18, the swing block 18 blocks the swing frame assembly;

[0101] 3) The installation component drives the grabbing component to move to the track 5, uses the positioning unit 39 to clamp the rotation direction of the swing frame assembly, and after roughly positioning the swing frame assembly, the clamping unit 28 clamps the swing frame assembly;

[0102] 4) The horizontal movement cylinder 23 drives the grasping assembly to move in the horizontal direction. When the clamping unit 28 clamps the swing frame unit and moves, the swing frame assembly exerts force on the swing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com