Metal-modified hollow HZSM-5 catalyst for aromatization of glycerin and preparation method of metal-modified hollow HZSM-5 catalyst

A HZMS-5, metal modification technology, which is applied in the field of fine chemicals, can solve the problems of short catalyst life and achieve the effect of simple modification method, easy control of loading capacity and easy control of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

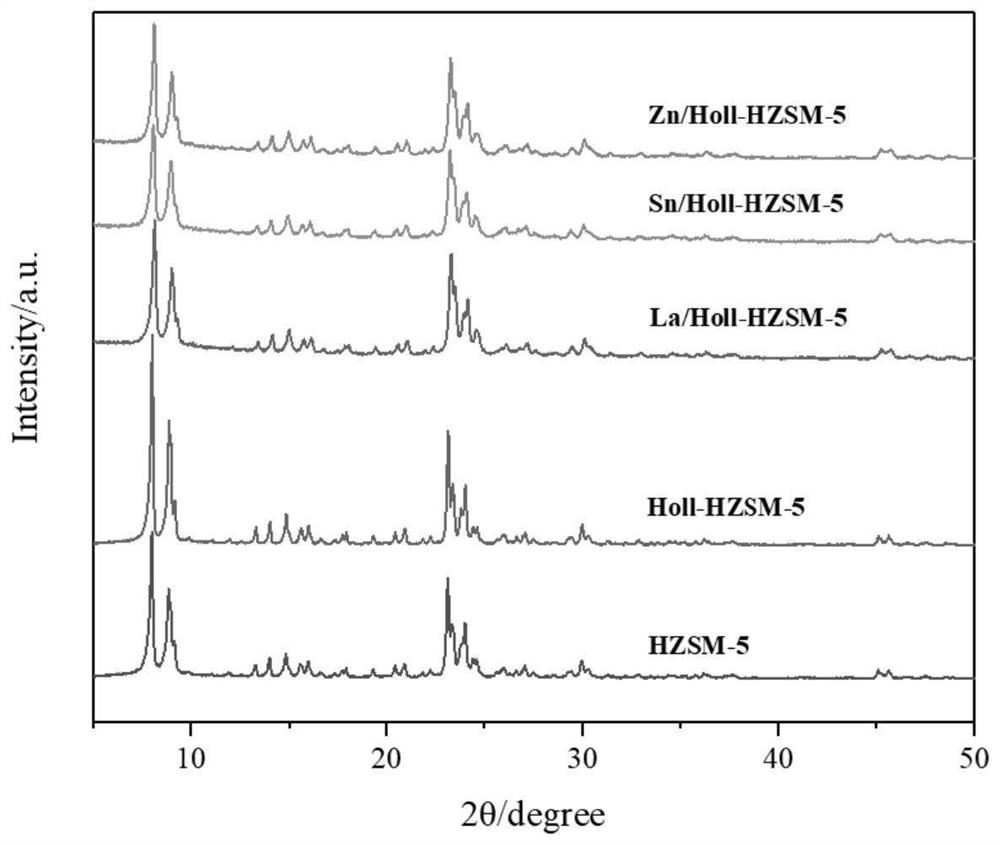

[0026] Mix 10g of HZSM-5 powder with 10% (mass percent) tetrapropylammonium hydroxide solution at a ratio of 10mL / g, then heat in a hydrothermal kettle at 180°C for 24h, then filter, wash, and dry at 100°C for 12h , Calcined at 540°C for 6h to obtain hollow HZSM-5. Mix 5g of hollow HZSM-5 with 10mL of 5% (mass fraction) zinc nitrate solution, sonicate for 5 minutes, let stand for 12 hours, then filter, wash, dry overnight, and roast at 500°C for 3 hours to obtain Zn-modified Hollow HZSM-5 molecular sieve catalyst, the catalyst TEM characterization results are as attached figure 1 As shown in (a), the hollow structure of the catalyst can be clearly seen, and the XRD characterization results are shown in the attached figure 2 As shown in the Zn / Holl-HZSM-5 curve, it can be seen that the catalyst has the characteristic peak of HZSM-5, and the result of ICP-AES shows that the content of Zn in the catalyst is 1.1%.

Embodiment 2

[0028] Mix 10g of HZSM-5 powder with 1% (mass percent) tetrapropylammonium hydroxide solution at a ratio of 20mL / g, then place in a hydrothermal kettle and heat at 200°C for 72h, then filter, wash, and dry at 100°C for 12h , Calcined at 540°C for 6h to obtain hollow HZSM-5. Mix 5g of hollow HZSM-5 with 20mL of 3% (mass fraction) tin chloride solution, sonicate for 30 minutes, let stand for 48 hours, then filter, wash, dry overnight, and bake at 500°C for 3 hours to obtain Sn-modified The hollow HZSM-5 molecular sieve catalyst. The TEM characterization results of the catalyst are attached figure 1 As shown in (b), the hollow structure of the catalyst can be clearly seen, and the XRD characterization results are shown in the attached figure 2 As shown in the Zn / Holl-HZSM-5 curve, it can be seen that the catalyst has the characteristic peak of HZSM-5, and the result of ICP-AES shows that the content of Sn in the catalyst is 1.2%.

Embodiment 3

[0030] Mix 10g of HZSM-5 powder with 50% (mass percent) tetrapropylammonium hydroxide solution at a ratio of 2mL / g, then place in a hydrothermal kettle and heat at 120°C for 4h, then filter, wash, and dry at 100°C for 12h , Calcined at 540°C for 6h to obtain hollow HZSM-5. Mix 5g of hollow HZSM-5 with 20mL of 15% (mass fraction) lanthanum nitrate mixed solution, sonicate for 15 minutes, let stand for 24 hours, then filter, wash, dry overnight, and roast at 500°C for 3 hours to obtain La modified The hollow HZSM-5 molecular sieve catalyst. The TEM characterization results of the catalyst are attached figure 1 As shown in (c), the hollow structure of the catalyst can be clearly seen, and the XRD characterization results are shown in the attached figure 2 As shown in the La / Holl-HZSM-5 curve, it can be seen that the catalyst has the characteristic peak of HZSM-5, and the result of ICP-AES shows that the content of La in the catalyst is 5.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com