Kneading equipment for cooked wheaten food processing

A kind of equipment and pasta technology, applied in the direction of mixing/kneading with horizontal installation tools, mixing/kneading with vertical installation tools, application, etc., can solve the problems of affecting the output speed of pasta, low degree of automation, high labor cost, etc., to achieve Convenient collection, good effect, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

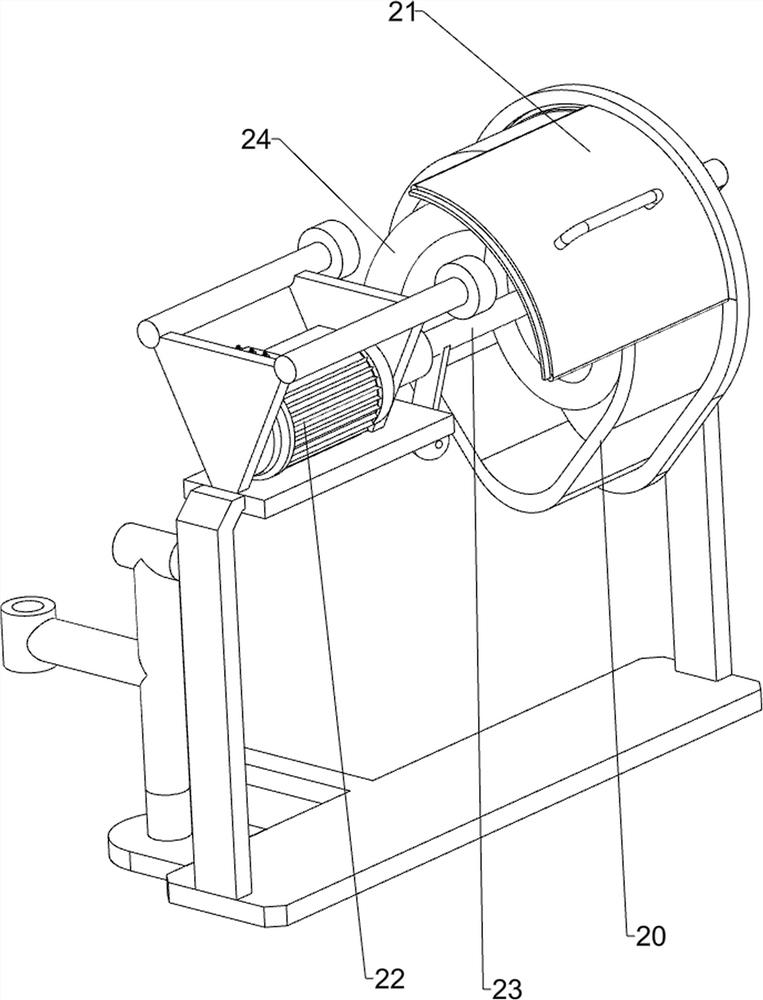

[0030] A kneading equipment for pasta processing, such as figure 1 , figure 2 with image 3 As shown, it includes a support frame 1 , a dough mixing assembly 2 and a feeding assembly 3 , the upper front side of the support frame 1 is provided with the mixing assembly 2 , and the lower side of the dough assembly 2 is provided with the feeding assembly 3 .

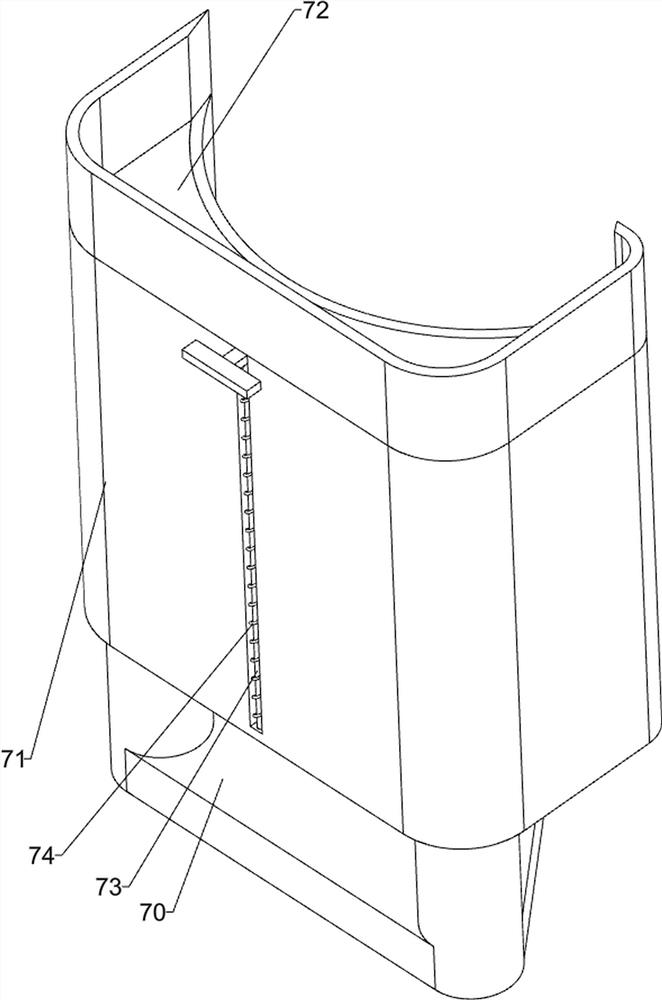

[0031] The dough mixing assembly 2 includes a mixing bucket 20, a cover plate 21, a motor 22, a first transmission shaft 23 and an agitator 24. The mixing bucket 20 is provided on the right front side of the upper part of the support frame 1, and the upper right side of the mixing bucket 20 is slidingly provided with a cover plate. 21. A motor 22 is provided on the left side of the upper part of the support frame 1, and a first transmission shaft 23 is provided in the middle of the mixing bucket 20 in a rotating manner. The left side of the first transmission shaft 23 is connected to the output shaft of the motor 22. Stir...

Embodiment 2

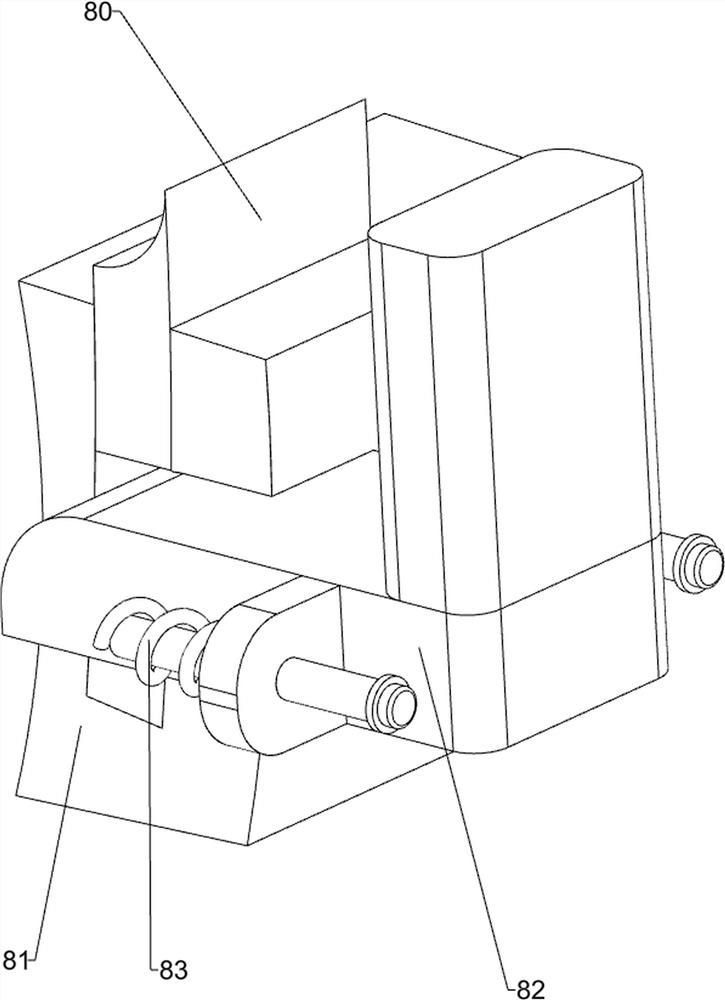

[0035] On the basis of Example 1, such as Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a fixed assembly 4 is also included, and the fixed assembly 4 includes a fixed block 40, a slide bar 41, a block 42, a first spring 43, a first wedge-shaped rod 44 and a second spring 45, and the front and rear of the bottom right side of the mixing bucket 20 Symmetry is provided with fixed block 40, and the inner side of fixed block 40 is all slidably provided with slide bar 41, and the inner side of slide bar 41 is all provided with clamping block 42, and clamping block 42 all cooperates with each other between stopper 36, same side slide bar 41 and The first springs 43 are connected between the fixed blocks 40, and the first springs 43 are respectively sleeved in the fixed blocks 40. The left side of the mixing bucket 20 is slidingly provided with a first wedge-shaped rod 44, and the first wedge-shaped rod 44 and the slide rod 41 Cooperating with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com