Calibration method, device, electronic equipment and storage medium for camera line deviation

A calibration method and line deviation technology, applied in the optical field, can solve the problems of depth data recovery failure, missing depth map, affecting the normal use of the camera, etc., to avoid efficient calibration, simplify the calibration procedure, and quickly put it back into use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

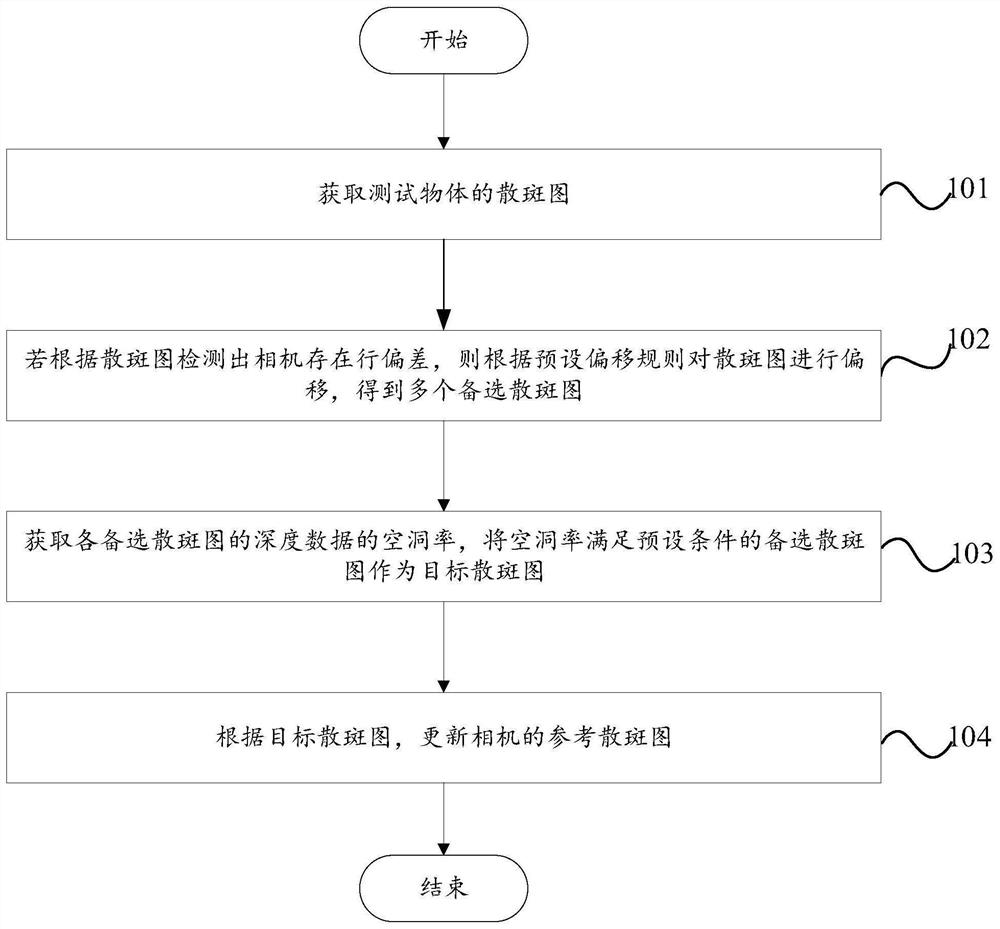

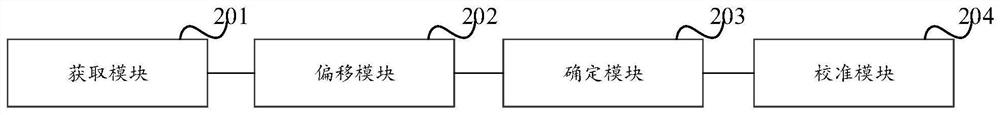

[0016] In order to achieve efficient detection and calibration of the line deviation existing in the camera, the embodiment of the present invention provides a

[0017] The camera line deviation calibration method provided by the embodiment of the present invention is based on the acquired speckle pattern of the test object.

[0019] The implementation details of the camera line deviation calibration method recorded in the application will be described below in conjunction with specific embodiments.

[0020] The first aspect of the embodiment of the present invention provides a camera line deviation calibration method, the specific camera calibration method [0020]

[0021] Step 101, obtain the speckle image of the test object.

[0026] In another example, after the calibration device obtains a candidate speckle pattern for each offset, the

[0027] Q

[0032] In an example, the calibration device uses the candidate speckle pattern whose void ratio satisfies a preset condition as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com