Building interior wall thickness detection method

A thickness detection, in-building technology, used in mechanical thickness measurement, measuring devices, mapping and navigation, etc., can solve the problems of cutting corners, unevenness, and inability to detect the flushness of walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

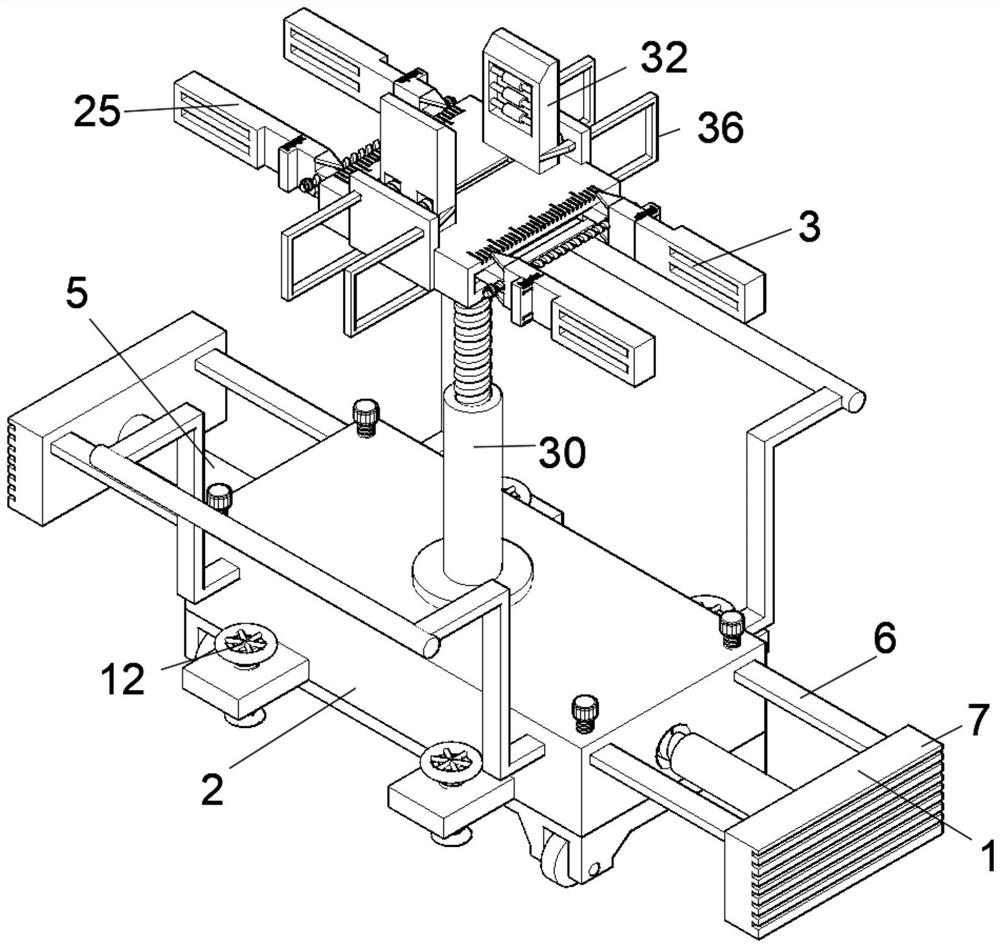

[0030] see Figure 1-2 , an embodiment provided by the present invention: a method for detecting the thickness of the inner wall of a building, comprising a mobile support chassis 2, the inner center of the mobile support chassis 2 is fixedly connected with a measuring buckle device 3, and the two ends of the mobile support chassis 2 slide symmetrically A fixed limit device 1 is plugged in;

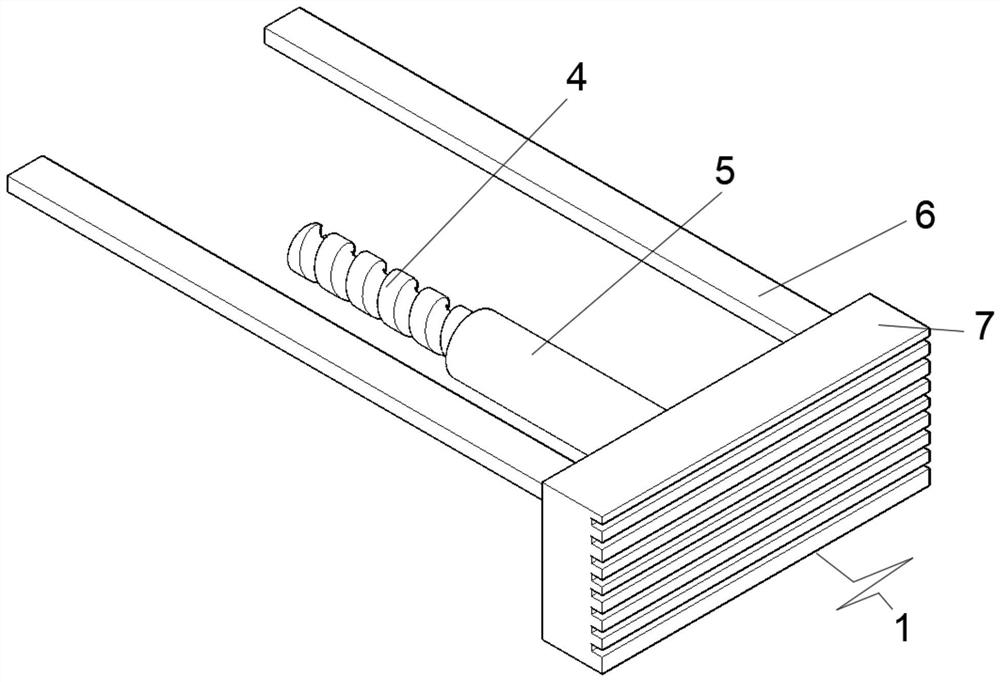

[0031] like image 3 , the fixed limit device 1 includes a fixed threaded rod 4, a threaded sleeve 5, a fixed limit insertion rod 6 and a moving contact clamp 7, the fixed threaded rod 4 is screwed into the inner center of the threaded sleeve 5, and the threaded sleeve 5 Rotationally connected to the center of one side of the mobile contact clamp 7 near the fixed threaded rod 4, the fixed limit insertion rod 6 is symmetrically fixedly connected to the side of the mobile contact clamp 7, and the fixed limit insertion rod 6 is located on both sides of the threaded sleeve 5. end;

[0032]...

Embodiment 2

[0040] On the basis of Example 1, such as Figure 10 As shown, the mobile pallet 32 also includes a protective gasket 37 and an anti-skid top plate 38, the protective gasket 37 is fixedly connected to the side end of the mobile pallet 32, the anti-skid top plate 38 is fixedly connected to the top of the mobile pallet 32, and the protective pad Sheet 37 and non-slip top plate 38 are made of wear-resistant plastics.

[0041] In the implementation of this embodiment, when the movable pallet 32 is a protective gasket 37 and an anti-slip top plate 38, the protective gasket 37 can be fixedly connected to the side end of the movable pallet 32, so that it can avoid friction with the wall , damage the mobile clamping plate 32, and fix it on the top of the mobile clamping plate 32 through the anti-slip top plate 38, which can avoid rigid collision with the wall when the wall is docked, and the materials of the protective gasket 37 and the anti-slip top plate 38 are resistant Grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com