Square steel column and I-shaped steel beam connecting structure

A connection structure, I-shaped technology, applied in the direction of building structure, construction, etc., can solve problems such as complicated procedures, and achieve the effect of realizing rigid connection, strengthening rigid connection, and reducing weakening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

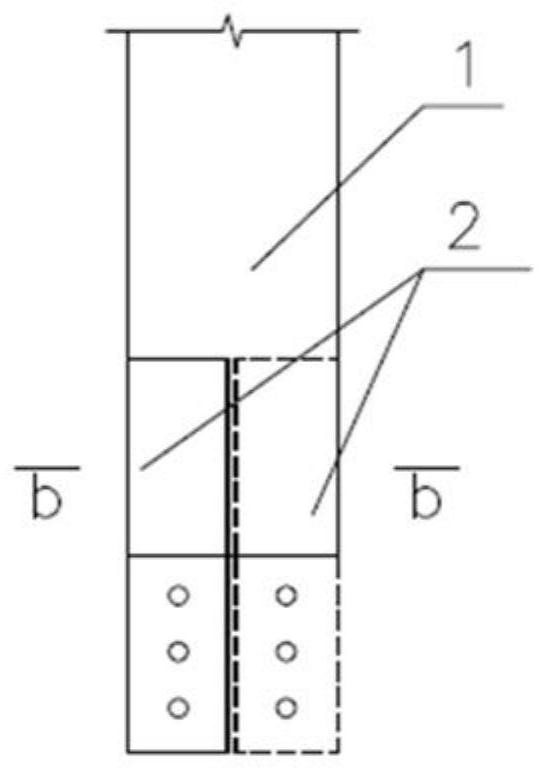

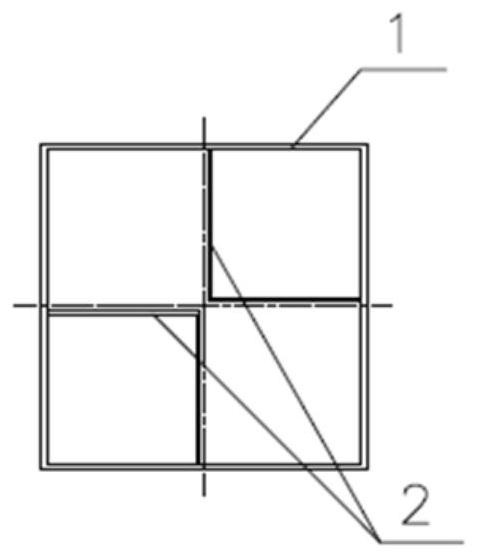

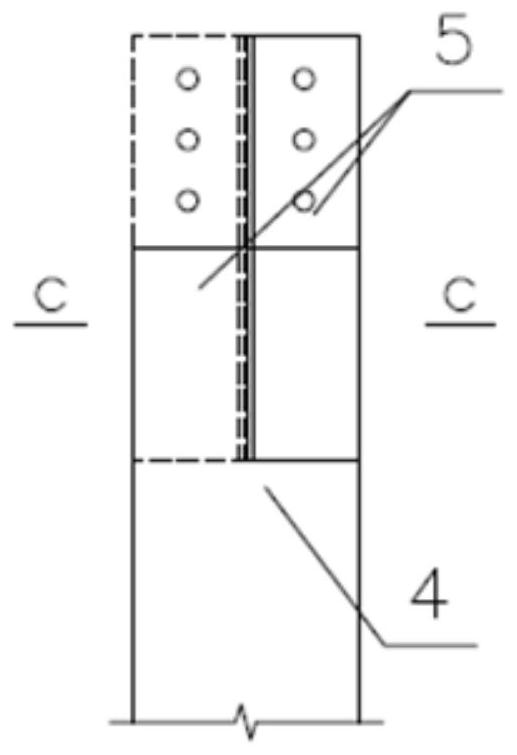

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1~4 Shown, the connection structure of square steel column and I-shaped steel beam of the present invention comprises steel column, I-shaped steel beam 3 and connector; Steel column comprises upper steel column 1 and lower steel column 4 that are arranged relatively, and upper steel The bottom of the column 1 and the top of the lower steel column 4 are provided with a cross-shaped groove, and the connecting parts include the upper steel column connecting part 2 and the lower steel column connecting part 5 placed up and down overlappingly, and the upper steel column connecting part 2 and the lower steel In the overlapping area of the column connector 5, the upper steel column connector 2 is provided with bolt hole I, and the lower steel column connector 5 is provided with bolt hole II; the upper steel column connector 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com