A kind of impact-resistant, flame-retardant liner and its preparation method

An impact-resistant, liner technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problem that products and raw materials without airworthiness certification, liners cannot meet the performance of civil aircraft, and affect phenolic materials Mechanical properties and other issues, to achieve the effect of optimization of composite material forming technology, optimization of liner configuration design, and reduction of raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

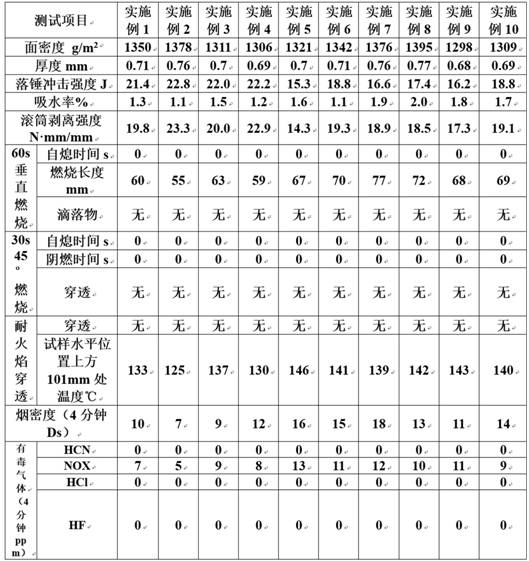

Examples

Embodiment 1

[0061] The impact-resistant and flame-retardant lining board of this embodiment is prepared by laying multi-layer phenolic resin prepreg, and the outermost layer of the phenolic resin prepreg is laid with a surface decorative film; the raw material for the preparation of the phenolic resin prepreg Includes phenolic resins and reinforcements. The area weight of phenolic resin prepreg is 400±20g / m 2 ; The content of phenolic resin in the phenolic resin prepreg is 44wt%~47wt%.

[0062] Wherein, the thickness of the surface decoration film is 25 μm; the color is white.

[0063] The reinforcing material is high-strength glass fiber fabric, the weaving method is satin weave, and it is a satin weave structure with eight three-flying weft surfaces.

[0064] The preparation raw material of phenolic resin comprises the following components according to the calculation in parts by mass:

[0065] 20 parts of thermoplastic phenolic resin, 80 parts of thermosetting phenolic resin, 2 part...

Embodiment 2

[0082] The impact-resistant and flame-retardant lining board of this embodiment is prepared by laying multi-layer phenolic resin prepreg, and the outermost layer of the phenolic resin prepreg is laid with a surface decorative film; the raw material for the preparation of the phenolic resin prepreg Includes phenolic resins and reinforcements. The area weight of phenolic resin prepreg is 400±15g / m 2 ; The content of phenolic resin in the phenolic resin prepreg is 38wt%~42wt%.

[0083] Wherein, the thickness of the surface decoration film is 25 μm; the color is white.

[0084] The reinforcing material is high-strength glass fiber fabric, the weaving method is satin weave, and it is a satin weave structure with eight three-flying weft surfaces.

[0085] The preparation raw material of phenolic resin comprises the following components according to the calculation in parts by mass:

[0086] 80 parts of thermoplastic phenolic resin, 20 parts of thermosetting phenolic resin, 7 part...

Embodiment 3

[0104] The impact-resistant and flame-retardant lining board of this embodiment is prepared by laying multi-layer phenolic resin prepreg, and the outermost layer of the phenolic resin prepreg is laid with a surface decorative film; the raw material for the preparation of the phenolic resin prepreg Includes phenolic resins and reinforcements. The area weight of phenolic resin prepreg is 360±10g / m 2 ; The content of phenolic resin in the phenolic resin prepreg is 42wt%~45wt%.

[0105] Wherein, the thickness of the surface decoration film is 25 μm; the color is white.

[0106] The reinforcing material is high-strength glass fiber fabric, the weaving method is satin weave, and it is a satin weave structure with eight three-flying weft surfaces.

[0107] The phenolic resin is calculated according to the mass parts and the preparation raw materials include the following components:

[0108] 80 parts of thermoplastic phenolic resin, 20 parts of thermosetting phenolic resin, 5 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com