Assembling and disassembling equipment, system and method for liquid trap welding tool pull rod of thermal management system

A technology of thermal management system and loading and unloading equipment, which is applied in the field of parts assembly, can solve the problems of easy to produce flexible shaking and low efficiency of the liquid collector rod, achieve high market promotion value, solve the effect of flexible shaking, and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

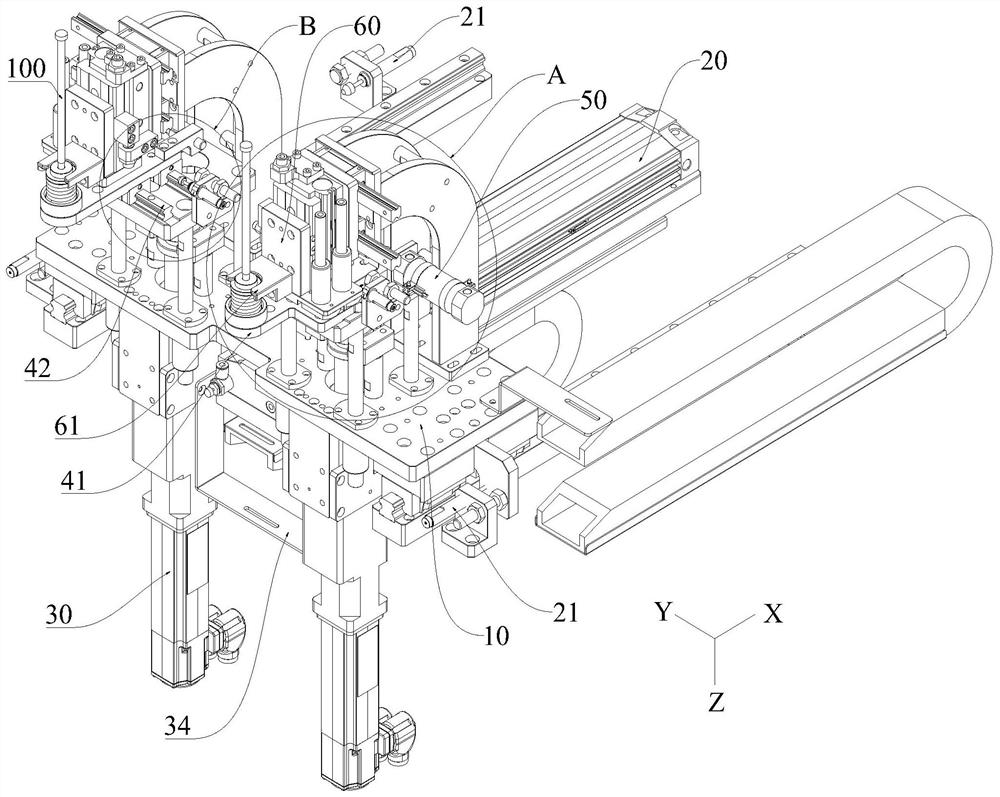

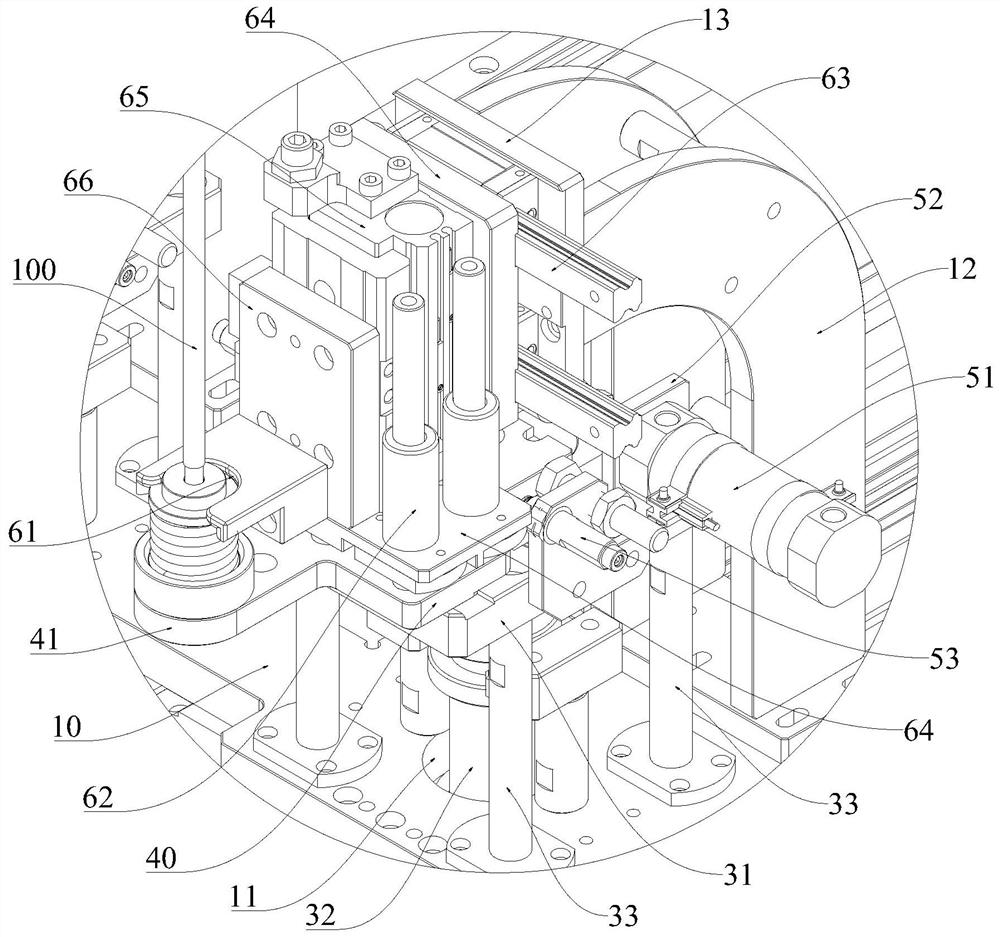

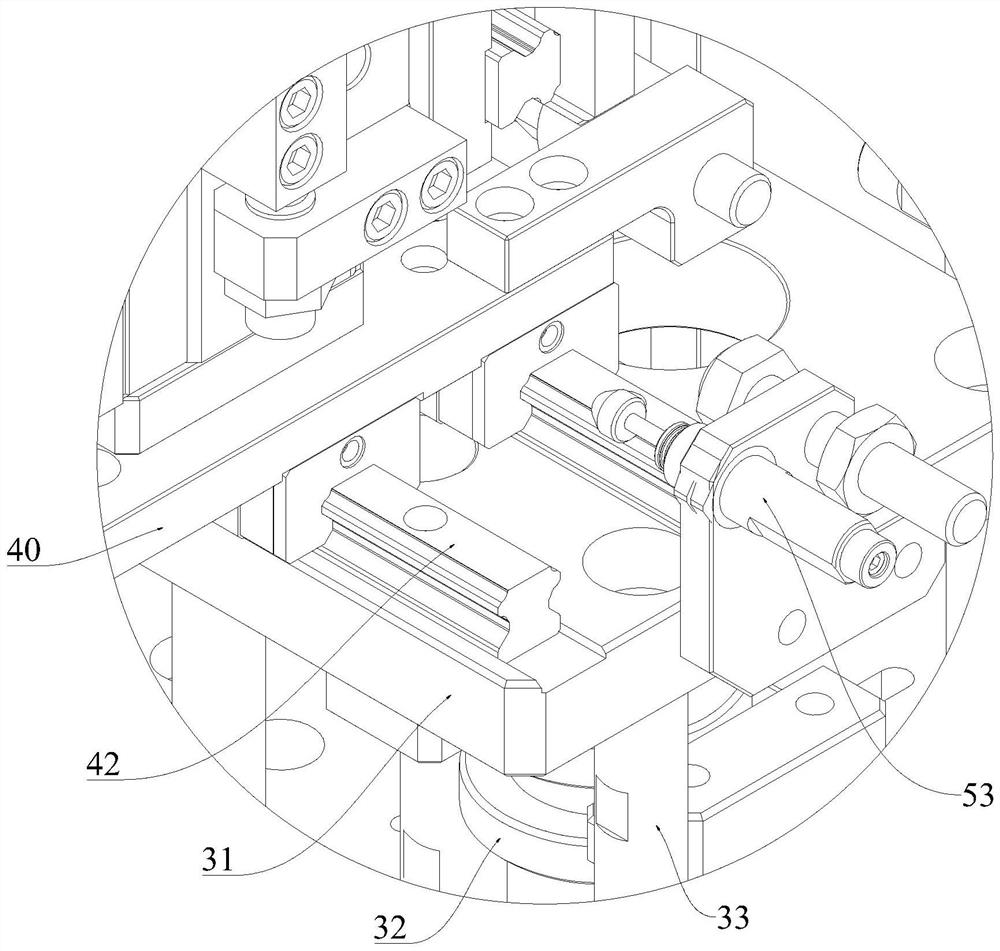

[0054] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the orientation nouns such as "up", "down", X-axis, Y-axis and Z-axis mentioned in this article are preceded by figure 1 orientation as a reference.

[0055] The invention provides a heat management system liquid collector welding tooling pull rod loading and unloading equipment, such as Figure 1 to Figure 6 As shown, it includes an installation platform 10 , an X-axis translation mechanism 20 , a Z-axis jacking mechanism 30 , a bearing plate 40 , a Y-axis translational mechanism 50 and a Z-axis pressing mechanism 60 . Wherein, the X-axis translation mechanism 20 can drive the installation platform 10 to move along the X-axis direction. The X-axis translation mechanism 20 can specifically include an X-axis transfer cylinder and an X-axis guide rail, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com