Preparation process of sulfonyl isocyanate with high conversion rate

A technology with high conversion rate of sulfonyl isocyanate, applied in the preparation of sulfonyl amide, organic chemistry, chemical instruments and methods, etc., can solve the problems of long cycle, low precision of phosgene introduction, complicated preparation process, etc., and achieve convenient operation , Improve the preparation conversion rate, improve the effect of the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

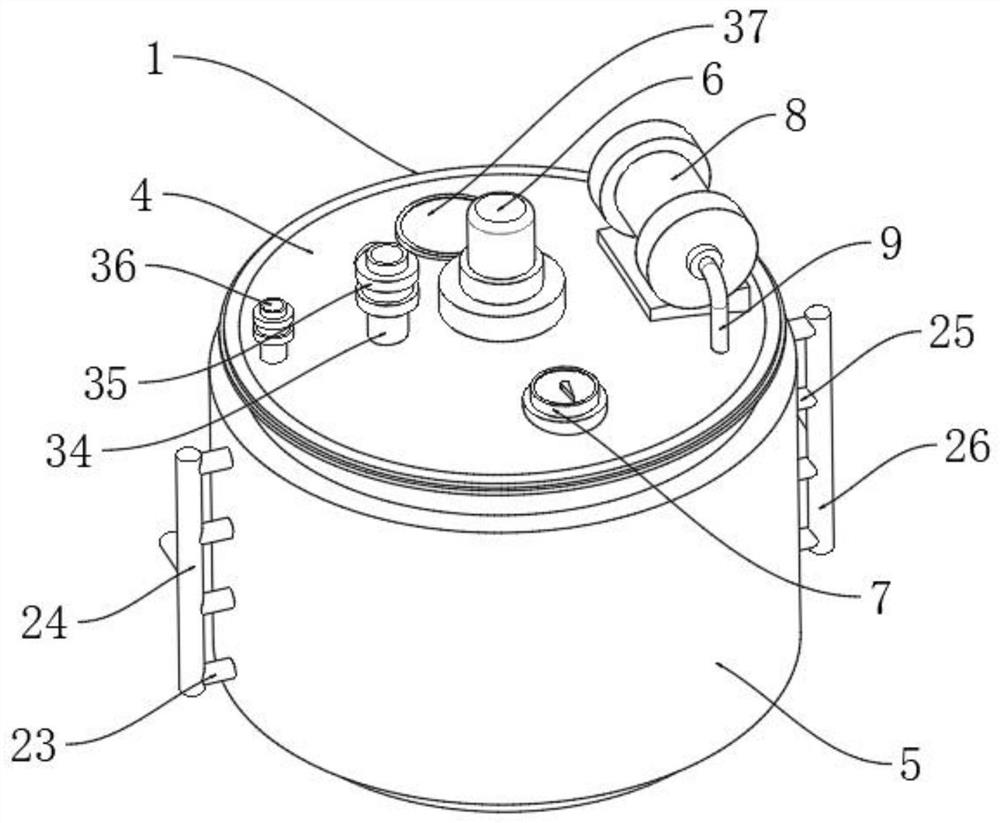

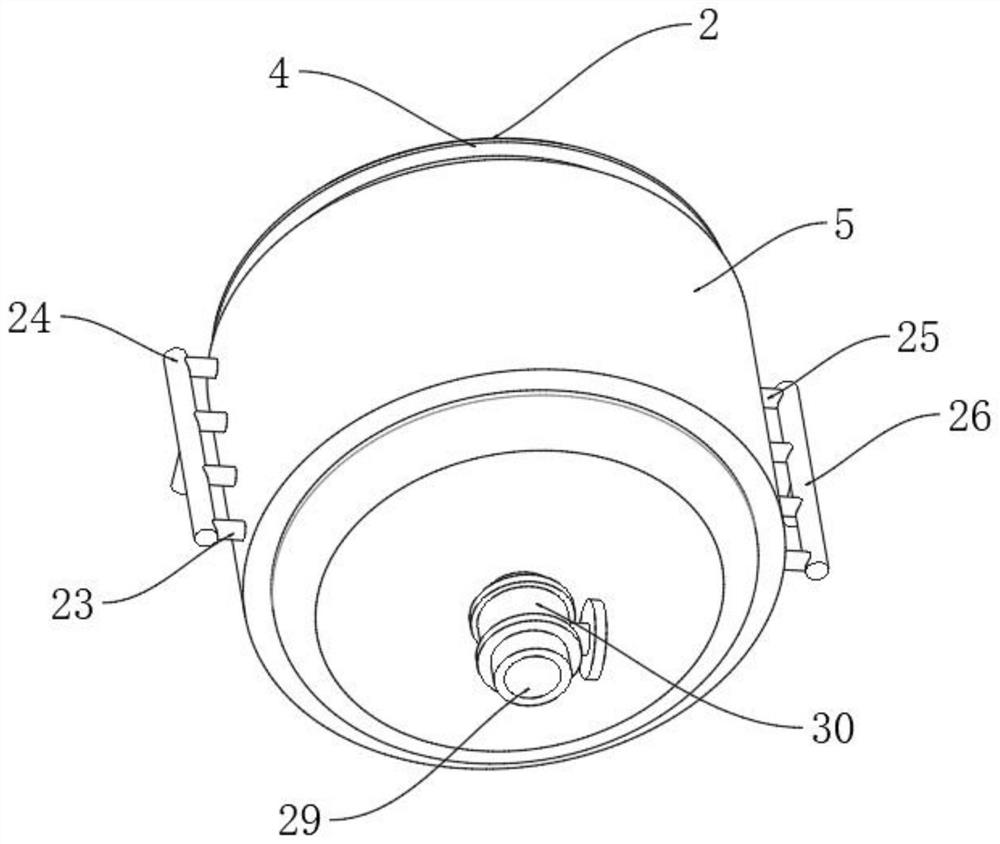

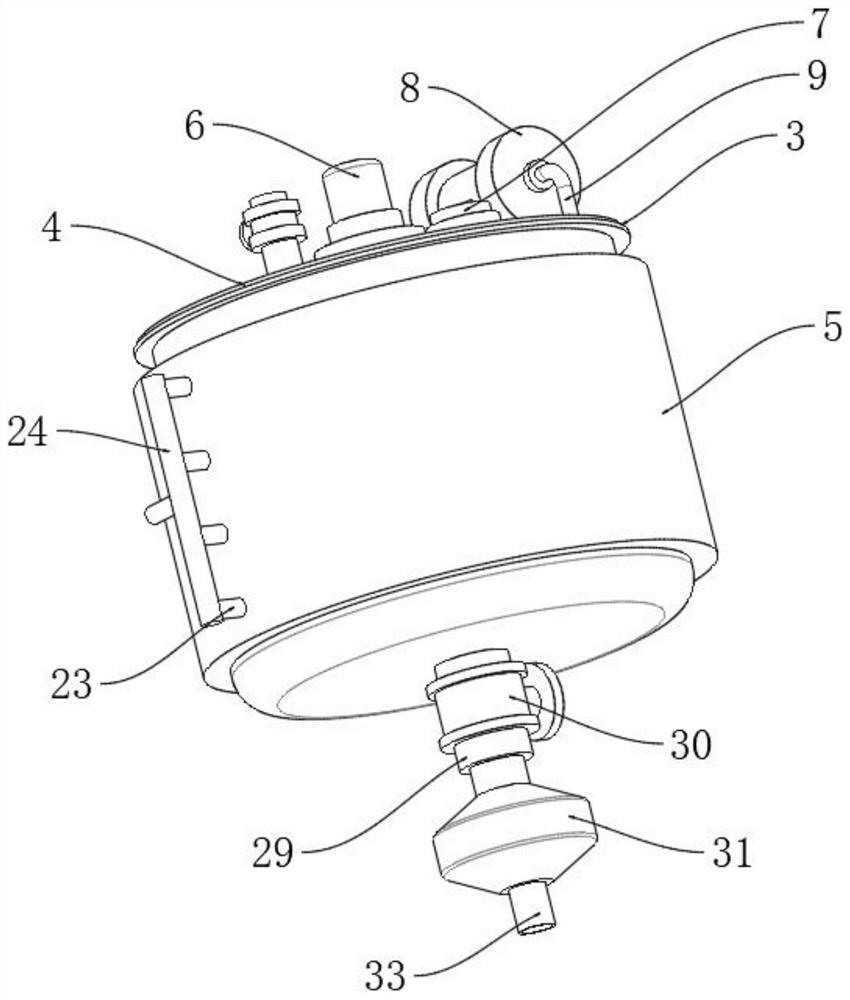

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0034] see Figure 1-7 , an embodiment provided by the present invention: a process for preparing sulfonyl isocyanate with high conversion rate, the sulfonyl isocyanate with high conversion rate is processed by a preparation device, and the preparation device includes a first reaction kettle 1, a second reaction kettle 2, a second reaction kettle Three reaction kettles 3, cover plates 4, heating and cooling jackets 5, motors 6, temperature controllers 7, pressurizing pumps 8, pressurizing pipes 9, solid phosgene dripping tanks 10, liquid outlet pipes 11, first solenoid valves 12 , measuring cylinder 13, force measuring rod 14, weighing and measuring module 15, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com