Cleaning type chip sorting device with suction nozzle convenient to disassemble and assemble

A sorting device, a clean technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inconvenient disassembly, influence on adsorption effect, easy leakage of screw-fixed structure, etc. Disassembly, convenient for inspection and cleaning, convenient for disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be described in conneffled and complete, and it is clear that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Embodiments in the present invention, those of ordinary skill in the art are in the range of protection of the present invention without making creative labor.

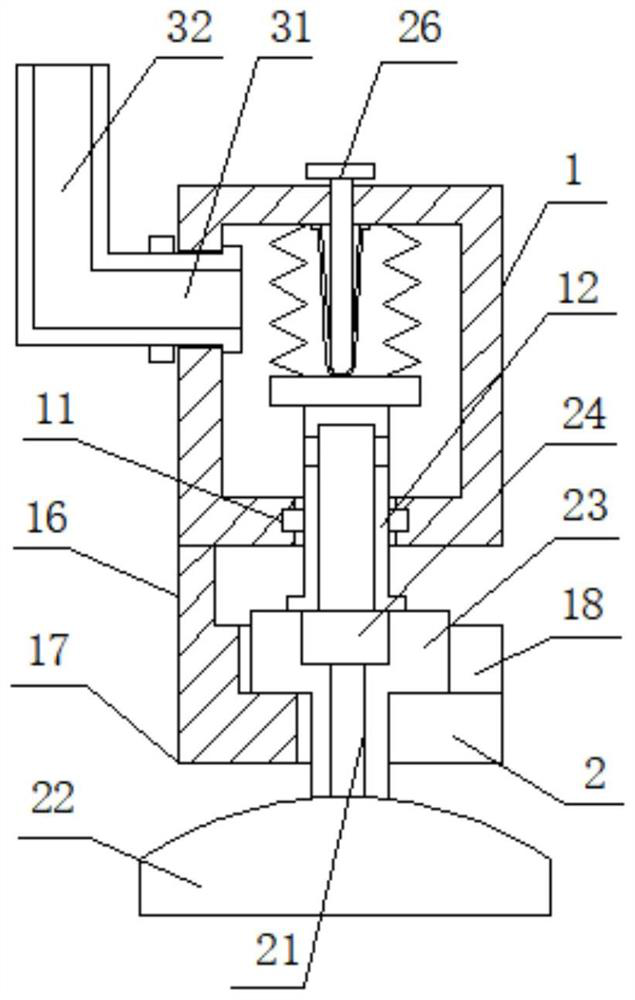

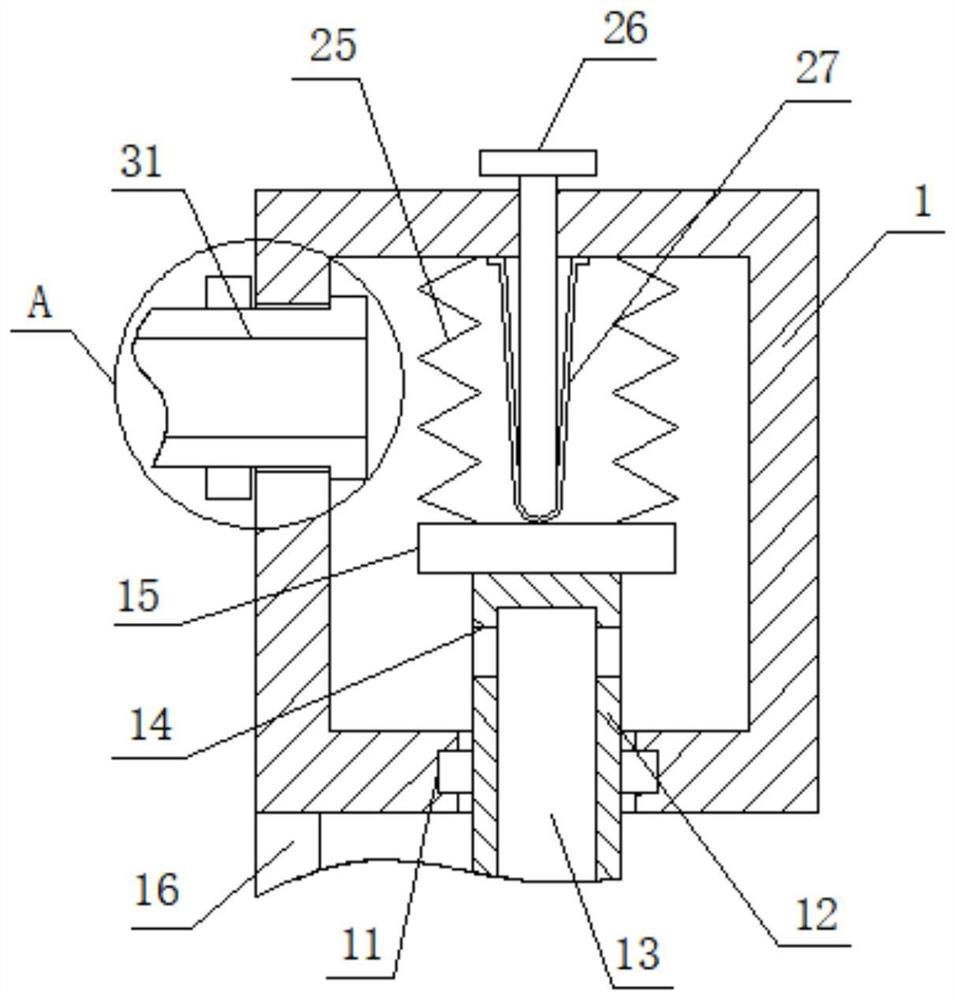

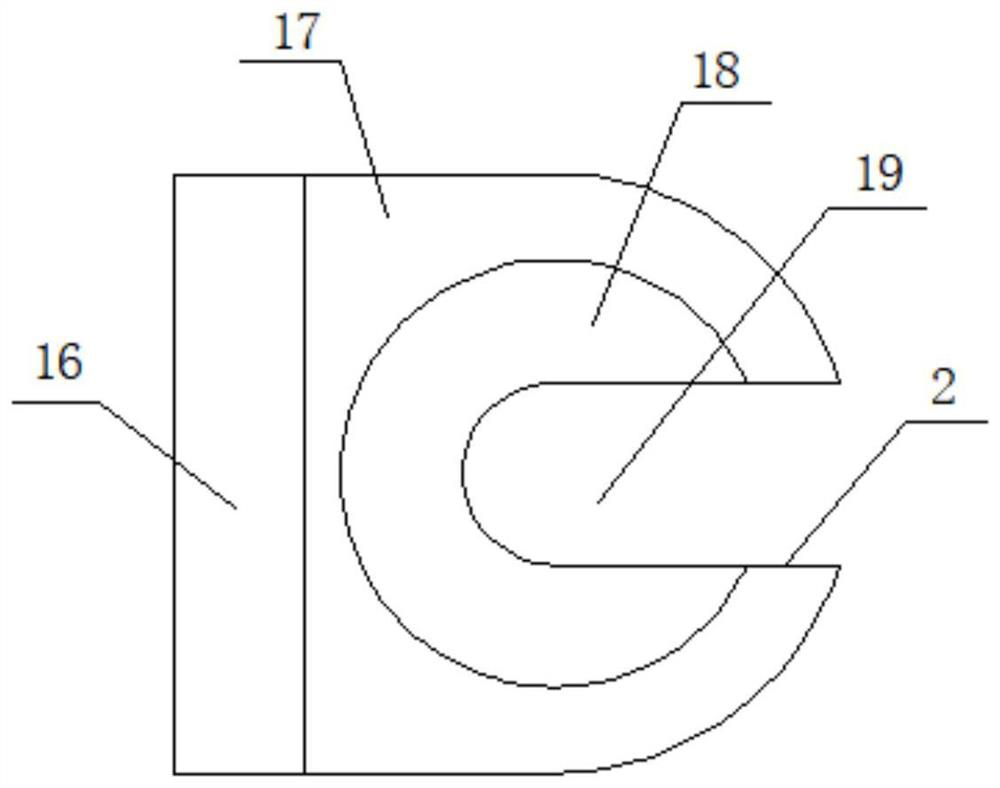

[0032] See Figure 1-4 A cleaning chip sorting device having a nozzle disassembly and installation, including a connecting barrel 1, see figure 1 , figure 2 with image 3 One end surface of the connecting barrel 1 is provided with a sealing hole 11, and the side surface of the sealing hole 11 is slidably mounted having a connecting tube 12, and one end surface of the connecting pipe 12 is provided with a cavity 13, and a communication hole 14 is provided on both sides of one end surface of the cavity 13. After the jacking pipe 12, the communication hole 14 is located inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com