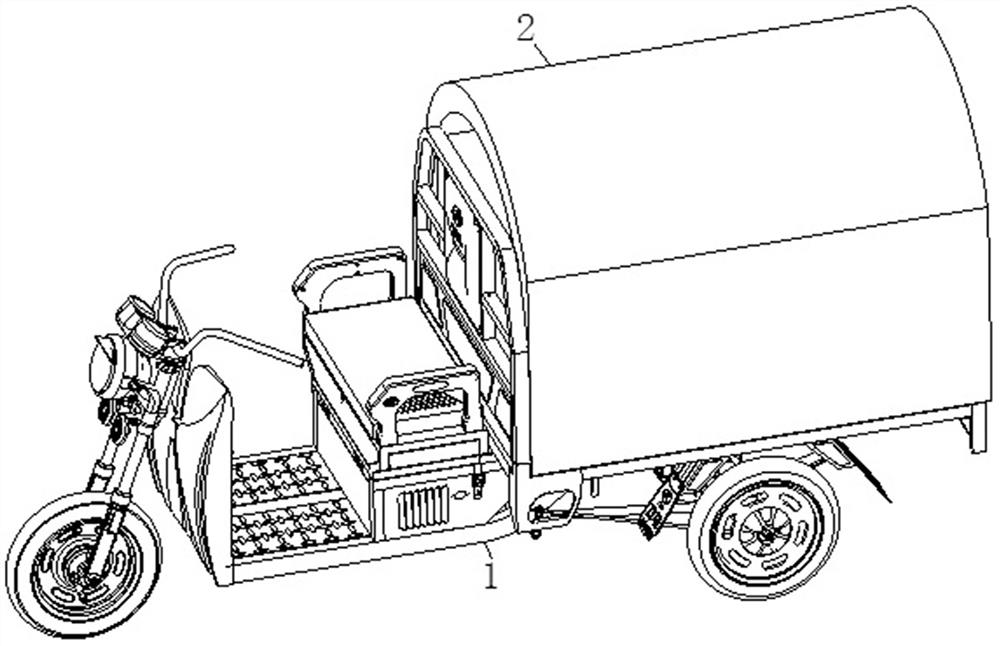

Electric tricycle for transportation

A technology of electric tricycles and carriages, which is applied in the direction of motor vehicles, transportation and packaging, vehicles with elevated loading platforms, etc., to achieve the effect of ensuring safety and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

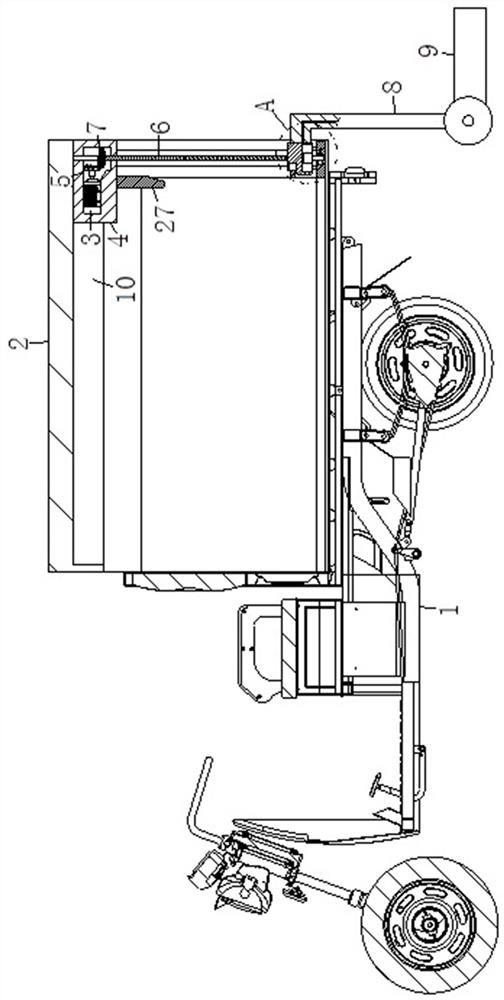

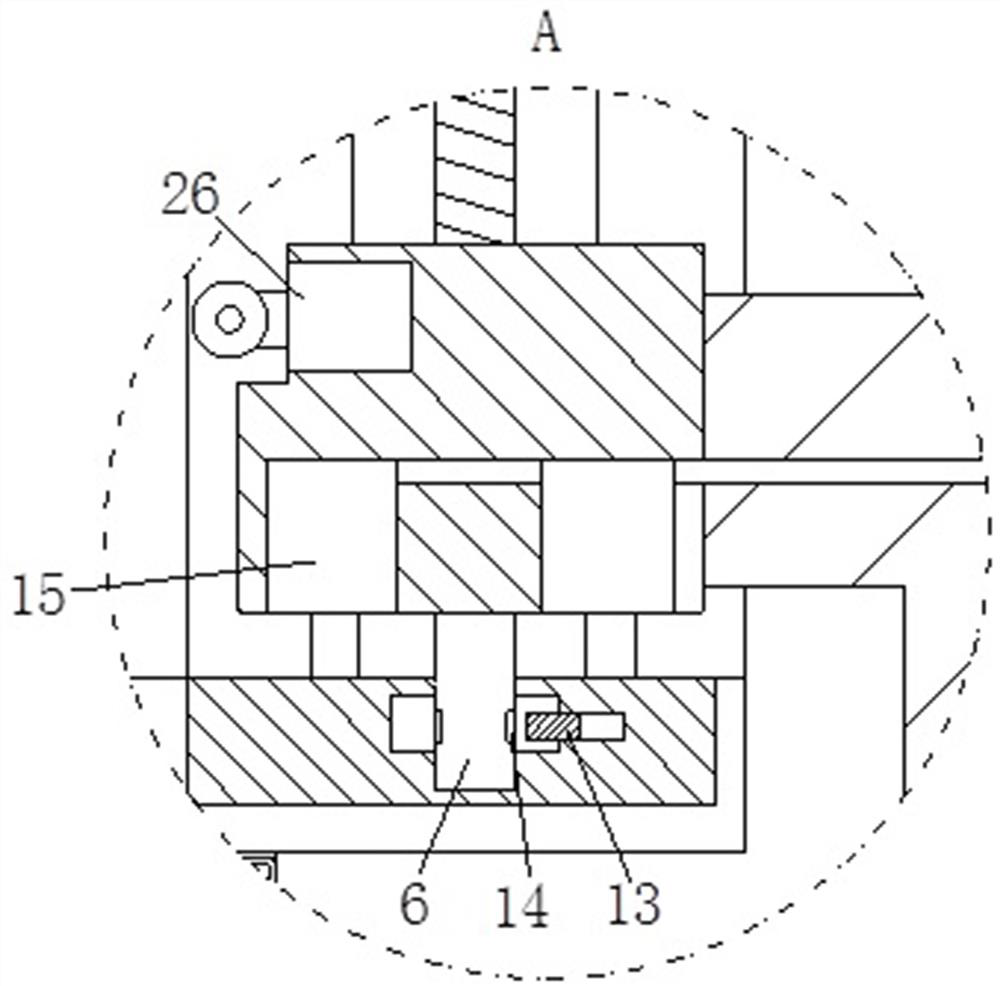

[0032] see Figure 1-Figure 6 As shown, an electric tricycle used for transportation includes a car body 1, a compartment 2 and a motor 3; the top of the car body 1 is fixedly connected with a compartment 2; the interior of the compartment 2 is provided with a connecting block near the rear of the vehicle 4; the inside of the connection block 4 is fixedly connected with a motor 3 near the top of the connection block 4; the output shaft of the motor 3 is fixedly connected with a first bevel gear 5; the surface of the connection block 4 is connected with a screw rod in rotation 6; the surface of the screw mandrel 6 is fixedly connected with the second bevel gear 7 near the top position of the screw mandrel 6, and the second bevel gear 7 is engaged with the first bevel gear 5; the nut of the screw mandrel 6 The surface is fixedly connected with a connecting rod 8; the surface of the connecting rod 8 is close to the bottom position of the connecting rod 8 and is connected with a p...

Embodiment 2

[0041] see Figure 7 with Figure 8 As shown, the positions between the two ball grooves 28 are equipped with mounting grooves; the inside of the mounting grooves are provided with balls 34; during work, by setting the balls 34 on the surface of the shaped plate 25, when the shaped plate When 25 is concave, the adjacent balls 34 will be squeezed together. At this time, the balls 34 in the squeezed state will not rotate directly to ensure the stability of the goods and personnel at this position. When in a flat state, the balls 34 stop squeezing each other, and the goods can be easily unloaded by pushing them.

[0042] The groove bottom of the safety groove 21 is fixedly connected with the second air bag 35 arranged evenly; Both are connected to each other through pipelines; the inside of the control groove 36 is fixedly connected with a telescopic bag 37; the top surface of the telescopic bag 37 is fixedly connected with a control block 38; the top surface of the control blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com