Rail vehicle aluminum profile self-positioning polishing tool

A rail vehicle, self-positioning technology, applied in the direction of grinding workpiece brackets, grinding machines, manufacturing tools, etc., can solve the problems of structural damage, assembly errors, time-consuming and other problems of the car body, and achieve the effect of precise placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

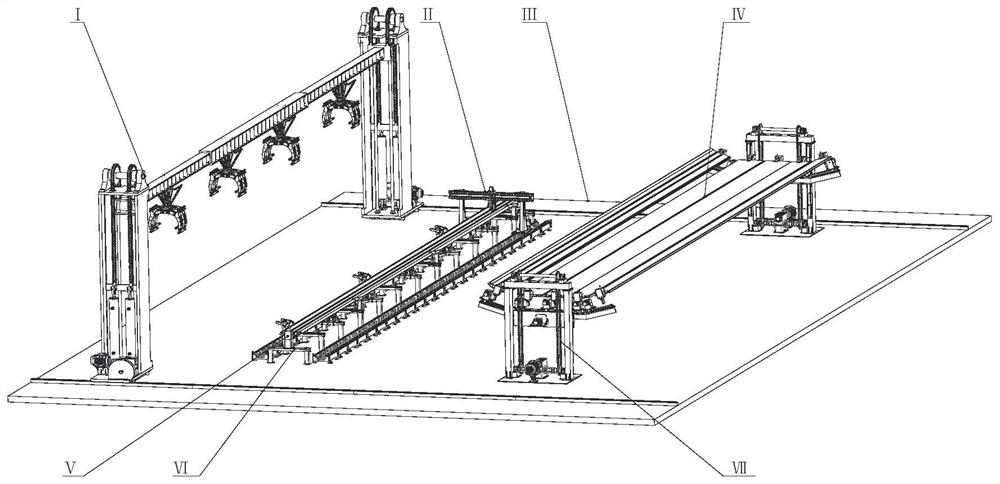

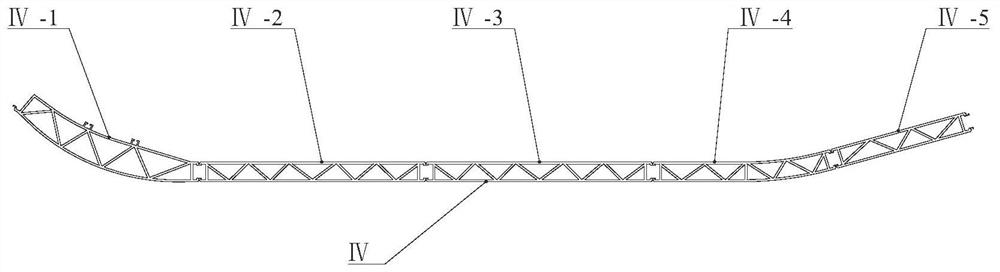

[0057] figure 1 for the overall schematic diagram. As shown in the figure, it mainly includes rail vehicle aluminum profile self-positioning and handling equipment Ⅰ, closed-loop grinding control system Ⅱ, floor Ⅲ, rail vehicle side wall hollow extruded aluminum alloy profile combination Ⅳ, self-positioning device Ⅴ, and aluminum profile grinding positioning clip Tight tooling Ⅵ and aluminum profile automatic assembly and welding front and back flip tooling Ⅶ.

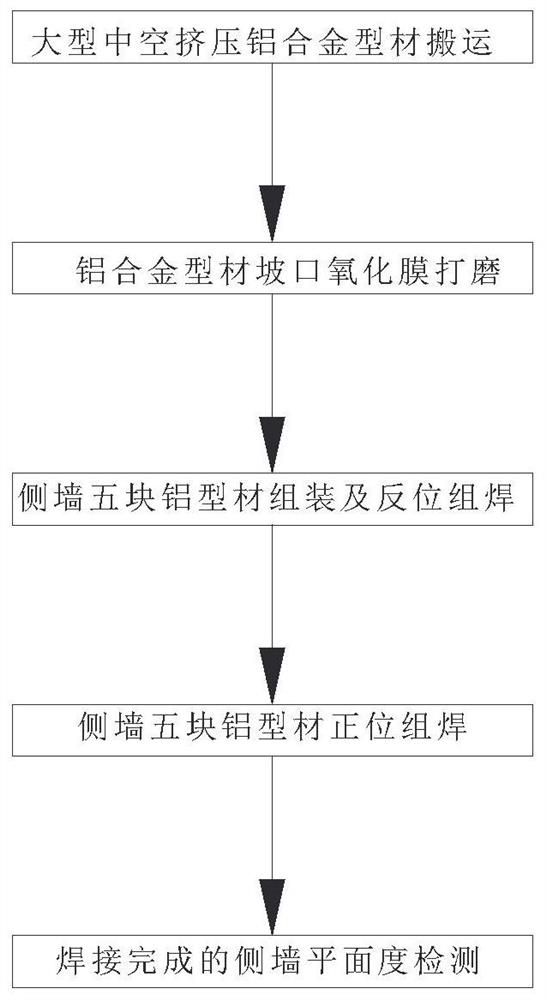

[0058] figure 2 Flow chart of manufacturing process for rail vehicle body side wall. As shown in the figure, the first step of the traditional side wall manufacturing process is: use the hoisting device to clamp the hollow extruded aluminum alloy profile with the processed groove from the material rack, hoist it, and install the aluminum profile grinding tool; the second step of the process is : Grinding the oxide film on the groove of the hollow extruded aluminum alloy profile; the third step of the process is: us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com