Internal cleaning type instrument and apparatus

A technology for instrumentation and internal cleaning, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc. The effect of avoiding disassembly and cleaning, avoiding secondary residues, and promoting thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

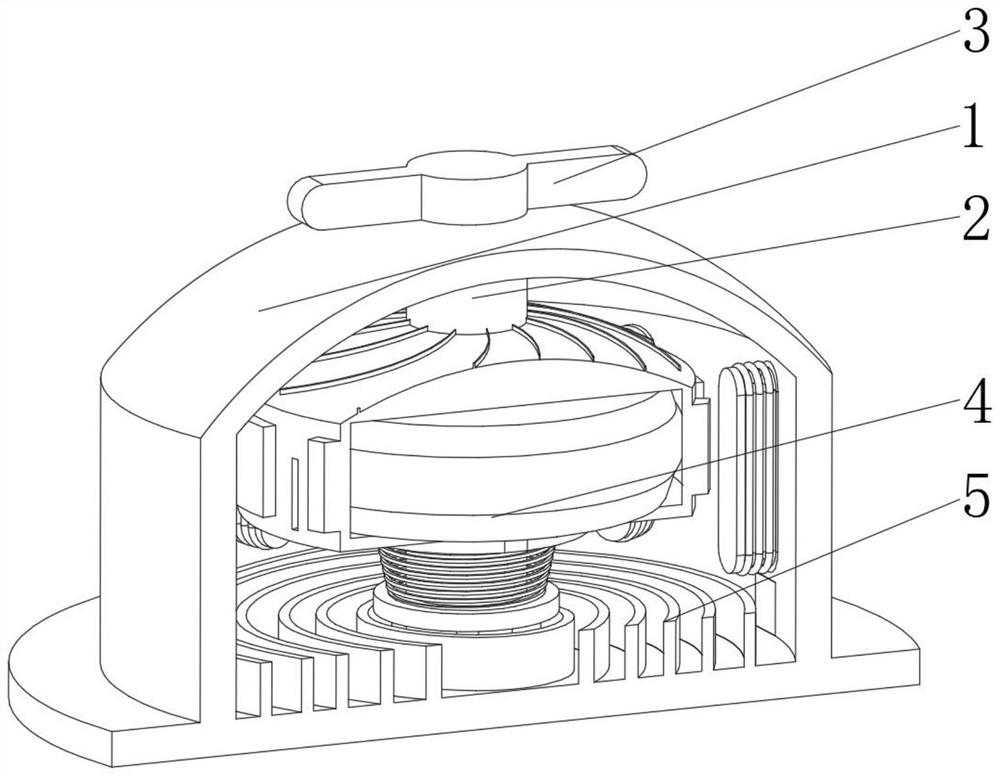

[0035] see Figure 1-3 , the present invention provides a technical solution: an internal cleaning instrument, specifically comprising:

[0036] Transparent cover 1, the transparent cover 1 has a spherical cover body, a rotating rod 2 installed in the middle of the spherical covering body, and a torsion plate 3 fixed on the top of the rotating rod 2; through the penetrating design of the rotating rod 2, the equipment can pass through Driven by external power, avoiding disassembly and cleaning of internal components, ensuring the tightness between components, and avoiding the cumbersome reassembly after disassembly.

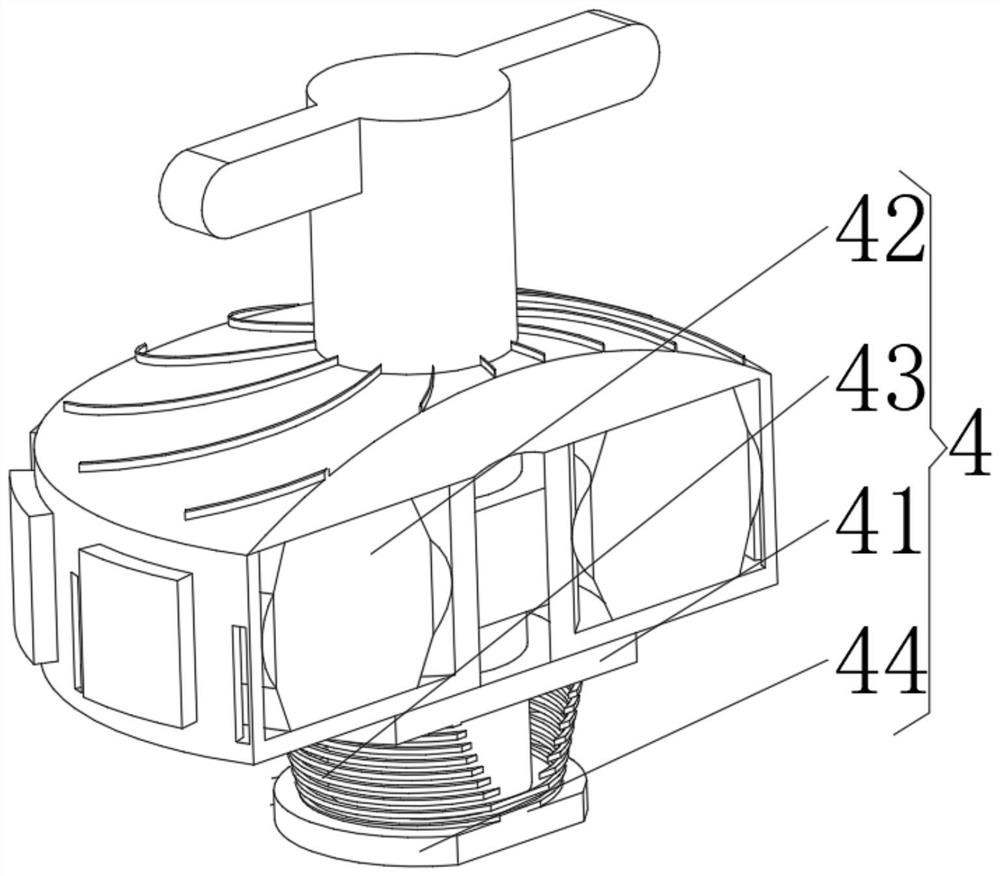

[0037] The instrument mechanism 4, the instrument mechanism 4 is installed in the middle of the outer surface of the rotating rod 2, and is installed on the protective mechanism 5 at the bottom of the instrument mechanism 4, the instrument mechanism 4 includes:

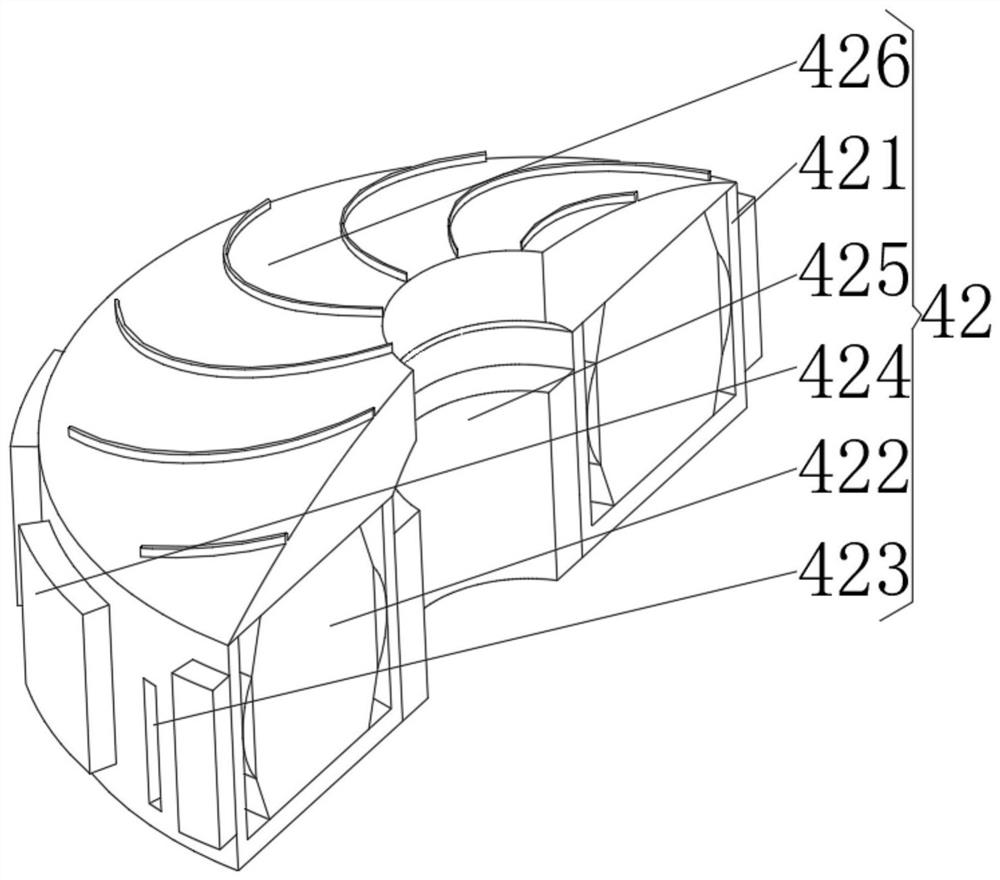

[0038] Top ring 41, the top ring 41 has a smooth ring plate, and a ventilation instrument 42 installe...

Embodiment 2

[0044] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: the annular instrument 422 includes an instrument ring a1, and a semi-annular capsule a2 fixed on the outer surface of the instrument annulus a1, and is set in the semi-annular capsule a2 The pressure balance hole a3 on the outer surface, and the arc spring plate a4 installed on the inner surface of the semi-circular capsule a2. The design of the elastic bag composed of the semi-circular bag a2 and the arc-shaped spring plate a4 can offset the impact force of the internal components when they rotate, and at the same time, the design of the pressure balance hole a3 balances the pressure inside and outside, and the airflow through the inside and outside of the component The mutual exchange of components restores the components, and the mutual exchange of internal and external airflow reduces the heat generated during the movement and prolongs the continuous working time of...

Embodiment 3

[0046] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the protective mechanism 5 includes: a bottom plate 51, which has a disc plate body, and a cross rod installed in the middle of the top of the disc plate body 52, and the ring box 53 that is fixed on the top of the disc plate body, and the ventilation hole 54 that is offered at the top of the disc plate body near the position of the ring box 53, and the clockwork spring 55 that is installed on the outer surface of the cross bar 52, and is fixed on The heating coil 56 on the inner surface of the ring box 53 . Utilizing the movement of the balance magnetic block 424 in Embodiment 1, the heating coil 56 can cut the magnetic induction coil, realize internal heating and heating, increase the volume of the internal air flow, and cooperate with the design of the different inclination angles of the inclined through hole 423 itself, so that the internal The unev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com