Straw cutting and arranging device and using method thereof

A technology of straightening and straw, which is applied in the field of straw cutting and straightening devices, can solve the problems of affecting farmers' use efficiency of fields, consuming more labor straw, and increasing farmers' labor intensity, so as to achieve thorough straw treatment, avoid straw dispersion, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

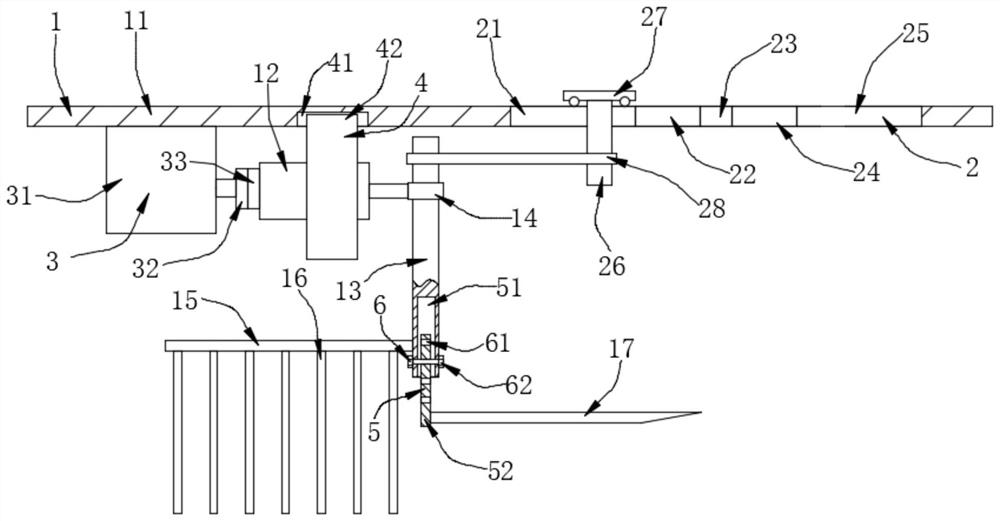

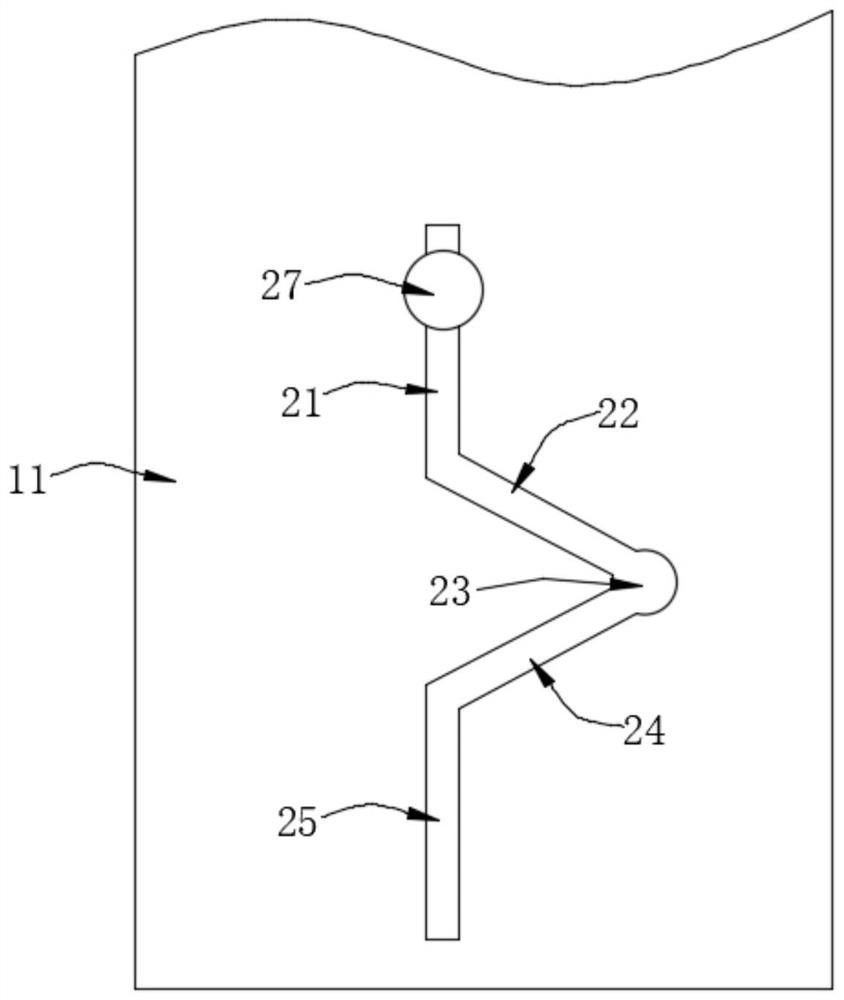

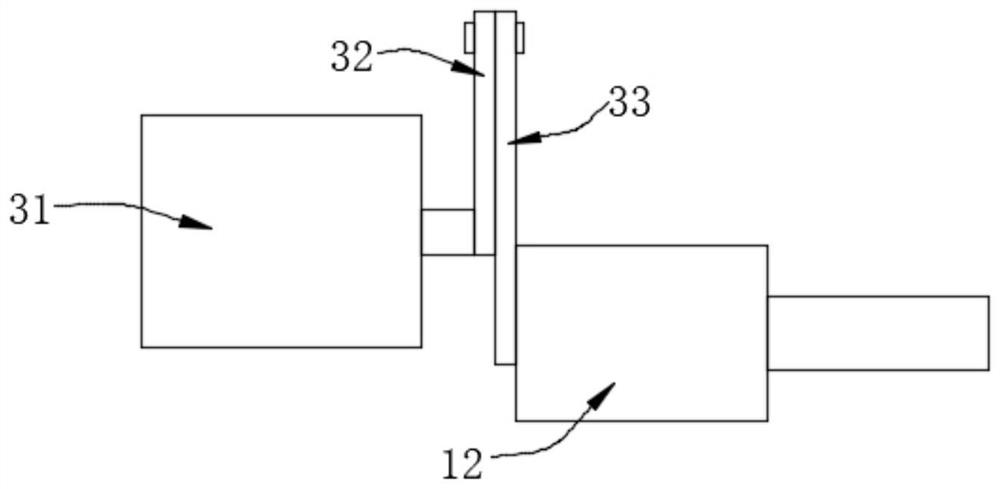

[0040] see Figure 1-4 , the present invention provides a technical solution: a rice straw cutting and regularizing device, including a main body component 1, a rotating component 2, a moving component 3, a limiting component 4, an adjusting component 5 and a fixing component 6:

[0041] The main body assembly 1 includes a beam plate 11, a telescopic rod 12, a first rod body 13, a collar 14, a first plate body 15, a driving rod 16 and a cutting knife 17;

[0042] The bottom of the beam plate 11 is provided with a telescopic rod 12, and one side of the telescopic rod 12 is provided with a first rod body 13, and the outer wall of the first rod body 13 is provided with a collar 14, and the inner side wall of the collar 14 is connected with the first rod body 13. The outer wall is rotationally connected, and one end of the telescopic rod 12 is fixedly connected to the outer wall of the collar 14;

[0043] A rotating assembly 2 is installed below the main assembly 1, a moving asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com