Auxiliary clamping device for airtightness detection of liquid cooling module

A technology of air tightness detection and clamping device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., which can solve the detection time lag and the time-consuming workpiece clamping. Effortless, unable to meet the use requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

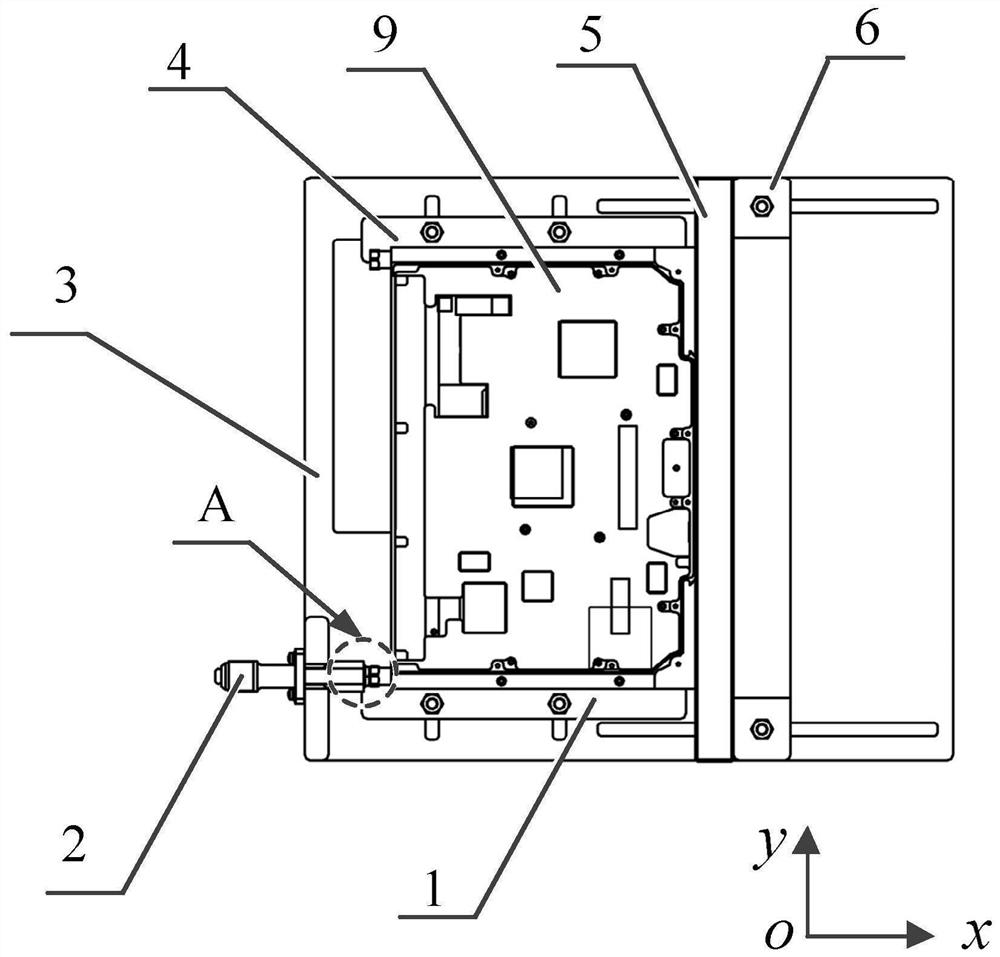

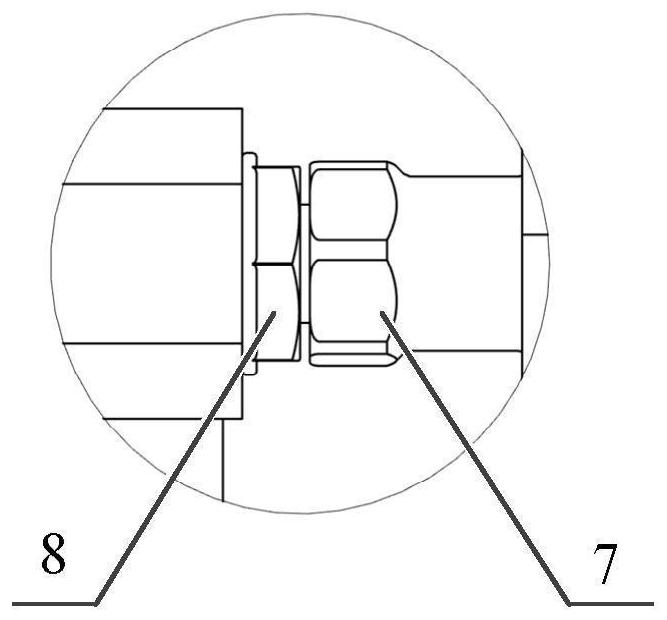

[0016] refer to Figure 1-Figure 3 . In the preferred embodiment described below, an auxiliary clamping device for airtight testing of a liquid-cooled module includes: a strip-shaped positioning bar 5 fixed on the seat plate 3 to clamp the liquid-cooled module 9 to be tested, characterized in that: The two sides of the positioning bar 5 are provided with the first mobile lock bar 1 and the second mobile lock bar 4 fixedly connected to the slide rails. The chute of the slide rail slides into the clamping area of the door-shaped angle plate formed symmetrically in the x direction, and is fixed on the bar-shaped positioning bar 5 by sliding adjustment through the screws on the two parallel angle plate chutes; the clamping is on the first The liquid cooling module 9 to be tested between the moving lock bar 1 and the second moving lock bar 4 slides towards each other, forming a clamping area with the x-direction positioning bar 5, and the detection head 2 is fixed on the seat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com